Preparation method for vildagliptin

A synthesis method and cyano technology, applied in the direction of organic chemistry and the like, can solve the problems of high price, low product purity, cumbersome vildagliptin reaction route, etc., and achieve a short reaction route, improve product purity, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention discloses a preparation method of vildagliptin, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. It needs to be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention, and relevant personnel can obviously make changes without departing from the content, spirit and scope of the present invention. Changes or appropriate changes and combinations are made to the content described herein to realize and apply the technology of the present invention.

[0023] In the present invention, unless otherwise specified, the scientific and technical terms used herein have the meanings commonly understood by those skilled in the art.

Embodiment 1

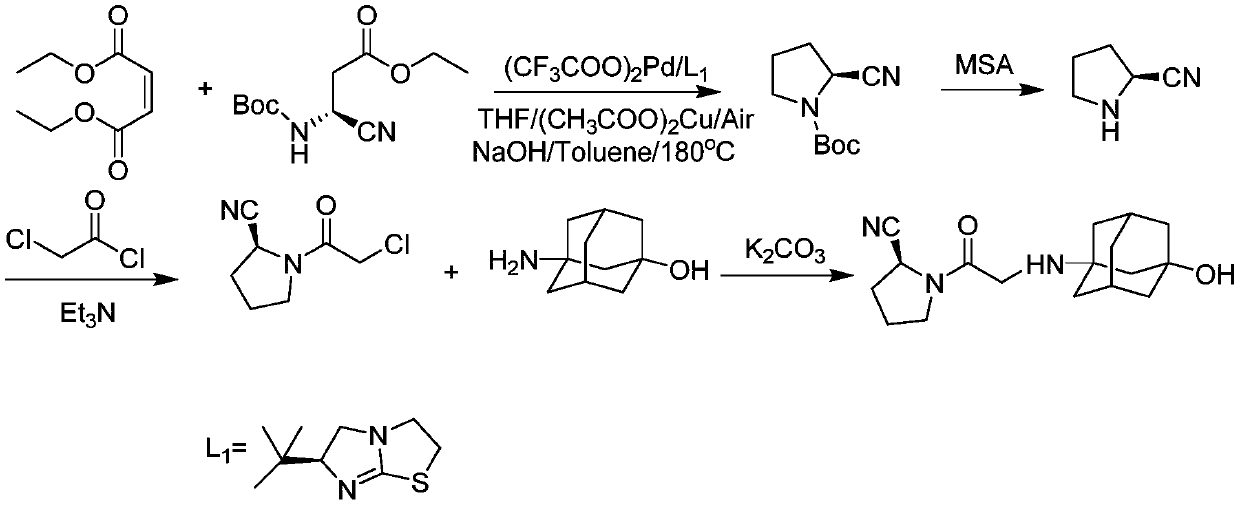

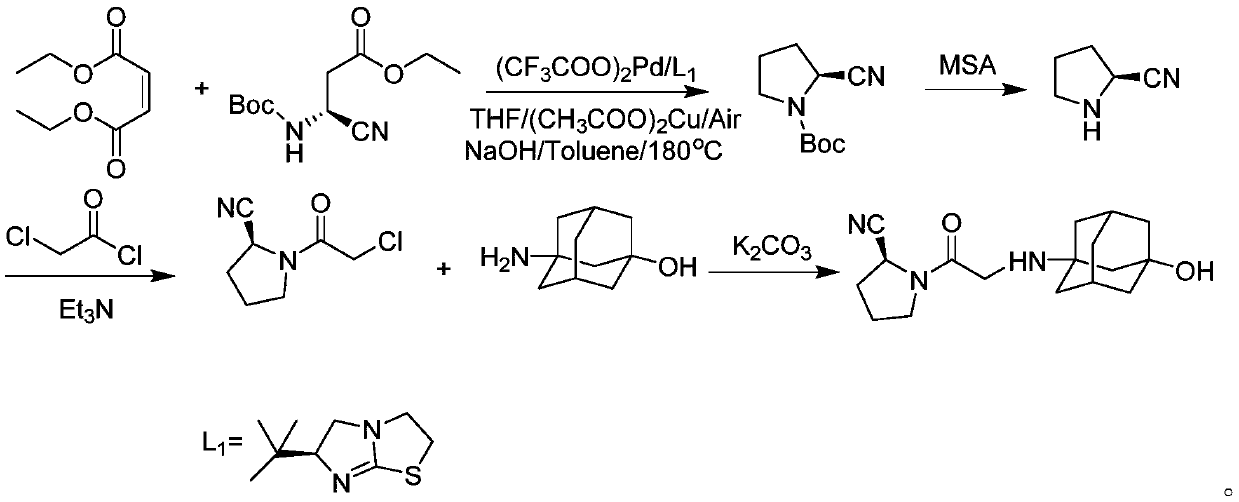

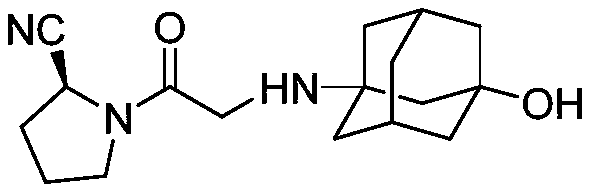

[0025] Embodiment 1: the preparation of (S)-2-cyano-pyrrolidine

[0026]

[0027] In 150mL tetrahydrofuran, add 8.25g (48mmol) butenedioic acid diethyl ester and 12.11g (50mmol) (S)-N-Boc-3-amino-3-cyano-propionic acid ethyl ester, in 0.20g ( In the presence of 0.6mmol) catalyst palladium trifluoroacetate, 0.15g (0.8mmol) 2-tert-butylimidazothiazole chiral ligand (L1) and 17.01g (85mmol) copper acetate, feed air and stir at 50°C for 3 Hours, TLC to monitor the reaction process, after the reaction is complete, add water to separate the layers, dry the organic phase with anhydrous magnesium sulfate overnight, concentrate under reduced pressure, dissolve 50mL of toluene, add 4.37g of solid sodium hydroxide, seal the tube and heat to 180°C under nitrogen protection, React for 10 hours, cool to room temperature, filter, remove the solvent under reduced pressure, and obtain compound (S)-N-Boc-2-cyano-pyrrolidine 8.93g (45.5mmol) through column chromatography, the yield is 95%, e...

Embodiment 2

[0029] Embodiment 2: the preparation of (S)-2-cyano-pyrrolidine

[0030] In 120mL tetrahydrofuran, add 5.16g (30mmol) butenedioic acid diethyl ester and 7.99g (33mmol) (S)-N-Boc-3-amino-3-cyano-propionic acid ethyl ester, in 0.17g ( In the presence of 0.5mmol) catalyst palladium trifluoroacetate, 0.33g (0.6mmol) 2-tert-butylimidazothiazole chiral ligand (L1) and 13.98g (70mmol) copper acetate, feed air, and stir at 40°C for 5 Hours, TLC monitors the reaction process, after the reaction is complete, add water to separate the layers, dry the organic phase with anhydrous magnesium sulfate overnight, concentrate under reduced pressure, dissolve 50mL of toluene, add 4.31g of solid sodium hydroxide, seal the tube and heat to 180°C under nitrogen protection, React for 10 hours, cool to room temperature, filter, remove the solvent under reduced pressure, and obtain compound (S)-N-Boc-2-cyano-pyrrolidine 5.63g (28.7mmol) through column chromatography with a yield of 96%. e.e. >99.9%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com