Technology for fluorinating unstable end group of perfluoropolyether

A perfluoropolyether, chemical process technology, applied in the field of fluorine chemical industry, can solve the problems of insufficient gas-liquid contact, increase the amount of exhaust gas, unfavorable environmental protection, etc. The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

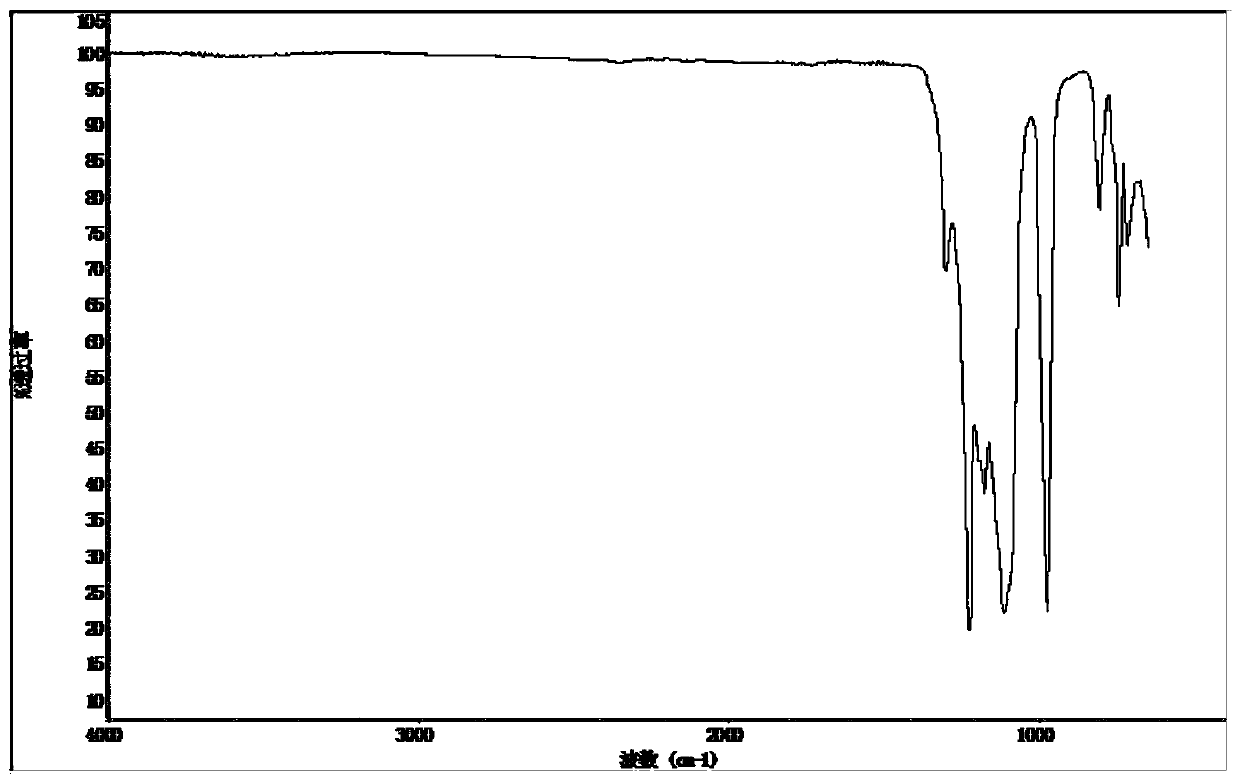

Image

Examples

Embodiment 1

[0052] Embodiment 1 provides a fluorination process for unstable terminal groups of perfluoropolyether, wherein the bubble column fluorination reactor used has a diameter of 20 cm and a height of 250 cm, and pumps 50 L of perfluoropolyether with a number average molecular weight of 5200 Da Ether acid fluoride raw material, and then the reactor is heated to 150°C, the circulation pump is turned on to circulate the material in the reactor, and the pressure of the back pressure valve is set to 0.5MPa. Open the fluorine gas valve, feed in a mixed gas of fluorine gas and nitrogen with a mass concentration of 50% fluorine gas, control the flow rate at 1.5g / min, and after ventilating for one hour, adjust the heating device of the bubble tower fluorination reactor to raise the temperature to 230°C and keep it for 24 hours Finally, stop feeding the mixed gas, turn off the heating, and feed nitrogen for purging. After the temperature drops to 40°C, stop nitrogen purging, open the discha...

Embodiment 2

[0054] Embodiment 2 provides a fluorination process for unstable terminal groups of perfluoropolyether, wherein the bubble column fluorination reactor used has a diameter of 20 cm and a height of 250 cm, and 50 L of perfluoropolyether with a number average molecular weight of 5200 Da Ether acid fluoride raw material, and then the reactor is heated to 150°C, the circulation pump is turned on to circulate the material in the reactor, and the pressure of the back pressure valve is set to 0.5MPa. Open the fluorine gas valve, feed in a mixed gas of fluorine gas and nitrogen with a mass concentration of 50% fluorine gas, control the flow rate at 1.5g / min, and after ventilating for one hour, adjust the heating device of the bubble tower fluorination reactor to raise the temperature to 230°C and keep it for 24 hours Finally, stop feeding the mixed gas, turn off the heating, and feed nitrogen for purging. After the temperature drops to 40°C, stop nitrogen purging, open the discharge va...

Embodiment 3

[0056] Embodiment 3 provides a kind of fluorination process of perfluoropolyether unstable end group, wherein the bubble column fluorination reaction equipment adopted is the same as that of embodiment 1, and the specific process includes pumping 50L of fluoride with a number average molecular weight of 3300Da after vacuuming. Perfluoropolyether acid raw material, and then the reactor is heated to 150°C, the circulation pump is turned on to circulate the material in the reactor, and the pressure of the back pressure valve is set to 0.5MPa. Open the fluorine gas valve, feed in a mixed gas of fluorine gas and nitrogen with a mass concentration of 50% fluorine gas, control the flow rate at 2.5g / min, and after ventilating for one hour, adjust the heating device of the bubble column fluorination reactor to raise the temperature to 255°C and keep it for 24 hours Afterwards, stop feeding fluorine gas, turn off the heating, and feed nitrogen gas for purging. After the temperature drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com