Method for preparing reinforced and toughened stimuli-responsive flexible packaging anti-oxidation composite film

A stimuli-responsive, enhanced and toughened technology, applied in coatings and other directions, can solve problems such as unresolved excitation mechanisms, achieve the effect of maintaining quality and safety, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Dispersion of carbon nanotubes in PET resin:

[0039] a. Prepare a mixture of phenol:tetrachloroethane=3:2 in parts by mass, stir evenly, and add carbon nanotubes (L-MWCNT-1020) and PET resin. Among them, the mass ratio of carbon nanotubes: PET resin: mixed solution is 1:100:450;

[0040]b. Use an ultrasonic cell disruptor to sonicate for two hours, stir at room temperature for three hours, repeat three times to form a homogeneous phase, and remove the solvent in a rotary evaporator;

[0041] c. Heat the PET containing carbon nanotubes at 120° C. for 20 hours in a vacuum drying oven.

[0042] (2) Preparation of modified BOPET:

[0043] d. Use a twin-screw extruder with a temperature of 200-230°C in the front section and a temperature of 230-250°C in the back section to re-granulate the mixture to form master batches, and dry them for later use.

[0044] e. Using the extruder, set the temperature on the panel to 200-250°C, set the screw speed to 40r / min, the speed...

Embodiment 2

[0072] (1) Dispersion of carbon nanotubes in PET resin

[0073] a. Prepare a mixture of phenol:tetrachloroethane=3:2 in parts by mass, stir evenly, and add carbon nanotubes (L-MWCNT-1020) and PET resin. Among them, the mass ratio of carbon nanotubes: PET resin: mixed solution is 1:120:480;

[0074] b. Use an ultrasonic cell disruptor to sonicate for two hours, stir at room temperature for three hours, repeat three times to form a homogeneous phase, and remove the solvent in a rotary evaporator;

[0075] c. Heat the PET containing carbon nanotubes at 120° C. for 20 hours in a vacuum drying oven.

[0076] (2) Preparation of modified BOPET:

[0077] d. Use a twin-screw extruder with a temperature of 200-230°C in the front section and a temperature of 230-250°C in the back section to re-granulate the mixture to form master batches, and dry them for later use.

[0078] e. Using the extruder, set the temperature on the panel to 200-250°C, set the screw speed to 45r / min, the speed...

Embodiment 3

[0101] (1) Dispersion of carbon nanotubes in PET resin

[0102] a. Prepare a mixture of phenol:tetrachloroethane=3:2 in parts by mass, stir evenly, and add carbon nanotubes (L-MWCNT-1020) and PET resin. Among them, the mass ratio of carbon nanotubes: PET resin: mixed solution is 1:140:500;

[0103] b. Sonicate for two hours with an ultrasonic cell disruptor, stir at room temperature for three hours, repeat three times to form a homogeneous phase, and remove the solvent in a rotary evaporator.

[0104] c. Heat the PET containing carbon nanotubes at 120° C. for 20 hours in a vacuum drying oven.

[0105] (2) Preparation of modified BOPET:

[0106] d. Use a twin-screw extruder with a temperature of 200-230°C in the front section and a temperature of 230-250°C in the back section to re-granulate the mixture to form master batches, and dry them for later use.

[0107] e. Using the extruder, set the temperature on the panel to 200-250°C, set the screw speed to 50r / min, the speed o...

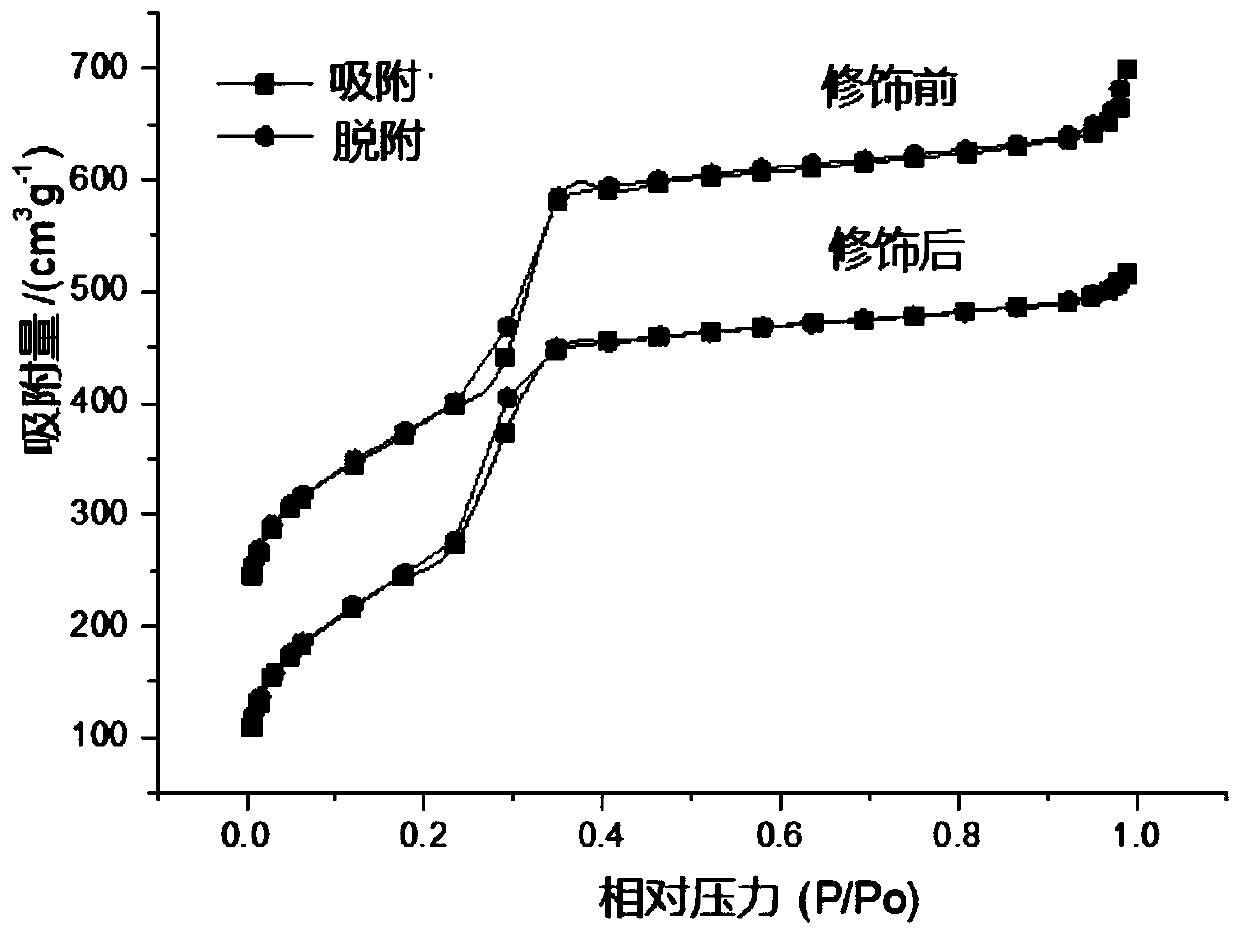

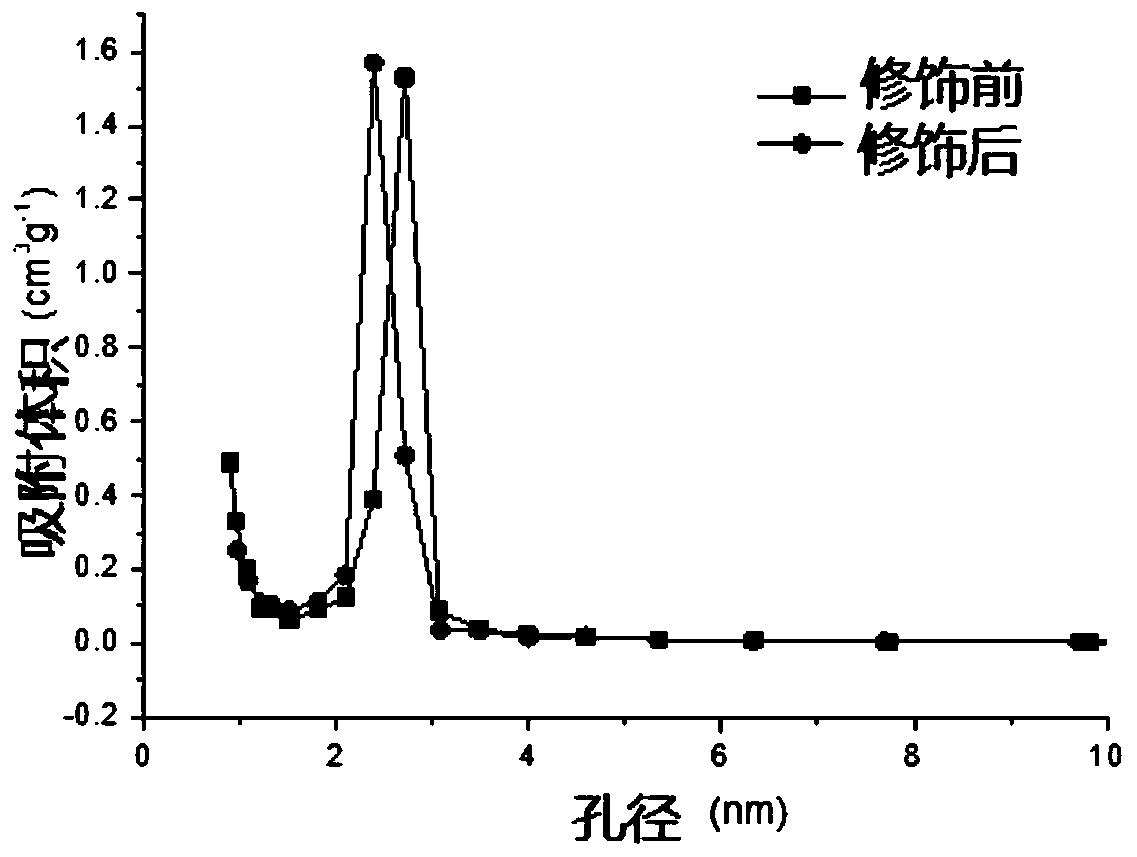

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com