Insulating material and polyethylene-based mica synergistically reinforced insulating and flame-retardant cable, and preparation methods thereof

A technology for reinforced insulation and flame retardant cables, which is applied in the direction of insulated cables, cable/conductor manufacturing, insulators, etc. It can solve problems such as the adverse effects of electrical properties, insulation properties and mechanical properties, and achieve the effect of comprehensive flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

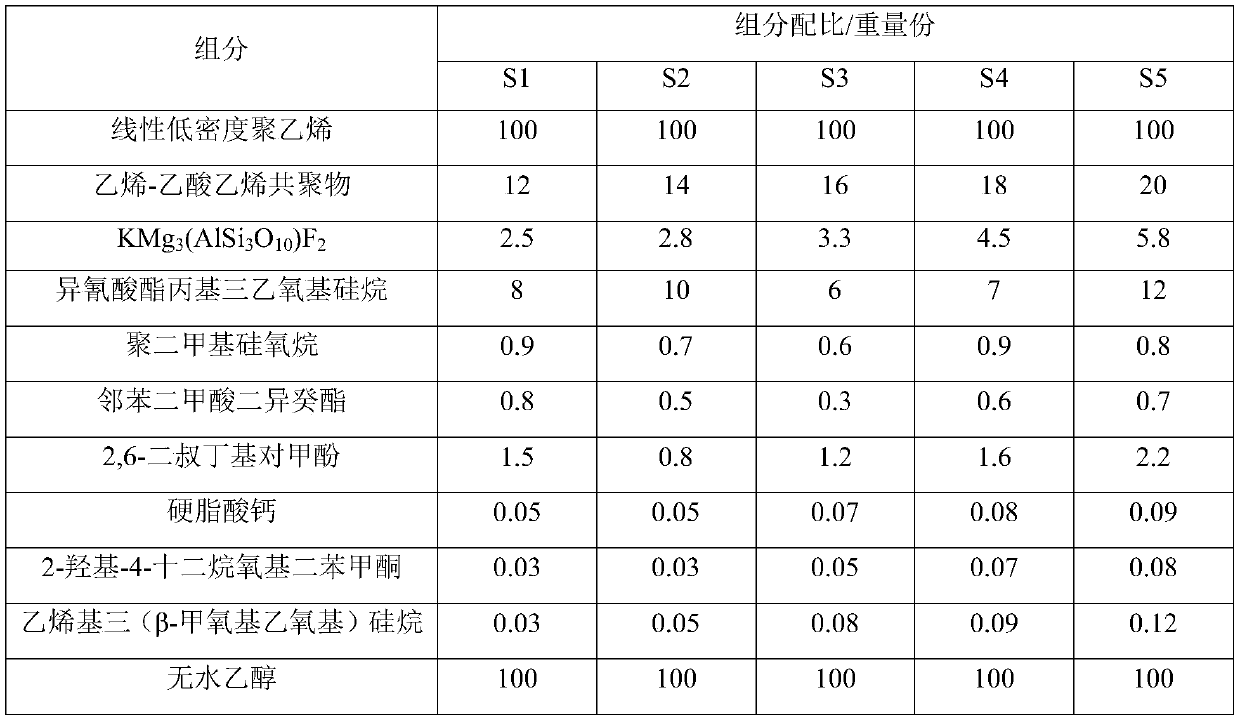

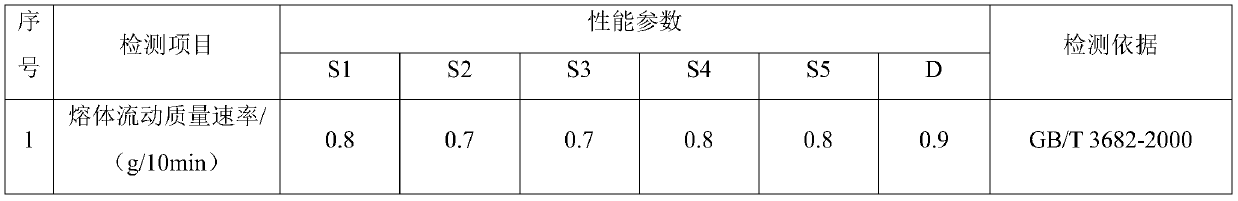

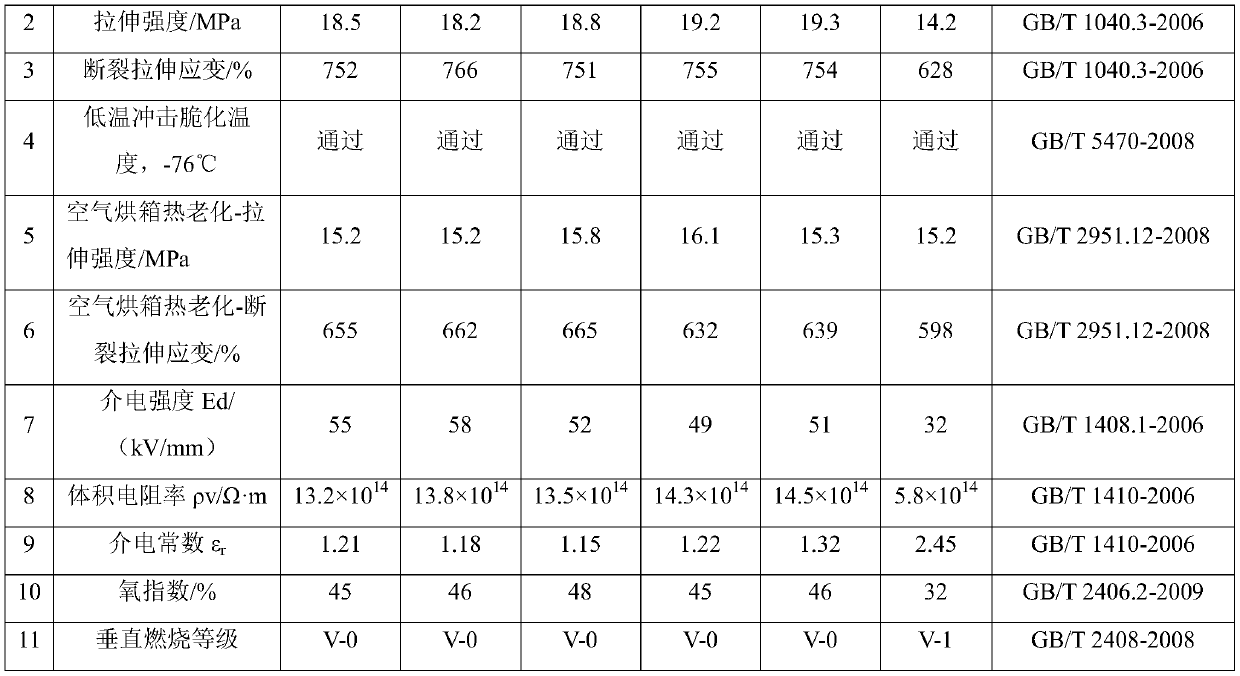

Embodiment 1

[0026] 1. Using annealed copper material to make a stranded conductor;

[0027] 2. Prepare 100 parts by weight of linear low density polyethylene, 12 parts by weight of ethylene-vinyl acetate copolymer, KMg 3 (AlSi 3 o 10 )F 2 2.5 parts by weight, 8 parts by weight of isocyanate propyl triethoxysilane, 0.9 parts by weight of polydimethylsiloxane, 0.8 parts by weight of diisodecyl phthalate, 2,6-di-tert-butyl p-cresol 1.5 parts by weight, 0.05 parts by weight of calcium stearate, 0.03 parts by weight of 2-hydroxy-4-dodecyloxybenzophenone, 0.03 parts by weight of vinyl tris (β-methoxyethoxy) silane, none 100 parts by weight of water ethanol, for subsequent use;

[0028]3. Add 0.03 parts by weight of vinyl tris(β-methoxyethoxy)silane to 100 parts by weight of absolute ethanol and mix thoroughly, and continue to add 2.5 parts by weight of mica (KMg 3 (AlSi 3 o 10 )F 2 ) powder, stirred at a constant temperature of 95°C for 25 minutes to obtain modified mica powder;

[00...

Embodiment 2

[0034] 1. Using annealed copper material to make a stranded conductor;

[0035] 2. Prepare 100 parts by weight of linear low density polyethylene, 14 parts by weight of ethylene-vinyl acetate copolymer, KMg 3 (AlSi 3 o 10 )F 2 2.8 parts by weight, 10 parts by weight of isocyanate propyl triethoxysilane, 0.7 parts by weight of polydimethylsiloxane, 0.5 parts by weight of diisodecyl phthalate, 2,6-di-tert-butyl p-cresol 0.8 parts by weight, 0.05 parts by weight of calcium stearate, 0.03 parts by weight of 2-hydroxy-4-dodecyloxybenzophenone, 0.05 parts by weight of vinyl tris (β-methoxyethoxy) silane, none 100 parts by weight of water ethanol, for subsequent use;

[0036] 3. Add 0.05 parts by weight of vinyl tris(β-methoxyethoxy)silane to 100 parts by weight of absolute ethanol and mix thoroughly, then continue to add 5.8 parts by weight of mica (KMg 3 (AlSi 3 o 10 )F 2 ) powder, stirred at a constant temperature of 95°C for 25 minutes to obtain modified mica powder;

...

Embodiment 3

[0042] 1. Using annealed copper material to make a stranded conductor;

[0043] 2. Prepare 100 parts by weight of linear low density polyethylene, 16 parts by weight of ethylene-vinyl acetate copolymer, KMg 3 (AlSi 3 o 10 )F 2 3.3 parts by weight, 6 parts by weight of isocyanate propyl triethoxysilane, 0.6 parts by weight of polydimethylsiloxane, 0.3 parts by weight of diisodecyl phthalate, 2,6-di-tert-butyl p-cresol 1.2 parts by weight, 0.07 parts by weight of calcium stearate, 0.05 parts by weight of 2-hydroxy-4-dodecyloxybenzophenone, 0.08 parts by weight of vinyl tris (β-methoxyethoxy) silane, none 100 parts by weight of water ethanol, for subsequent use;

[0044] 3. Add 0.08 parts by weight of vinyl tris(β-methoxyethoxy)silane to 100 parts by weight of absolute ethanol and mix thoroughly, then continue to add 3.3 parts by weight of mica (KMg 3 (AlSi 3 o 10 )F 2 ) powder, stirred at a constant temperature of 95°C for 25 minutes to obtain modified mica powder;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com