Method for preparing fermented soybean milk powder through lactobacillus fermentum, prepared fermented soybean milk powder and application

A technology of fermenting Lactobacillus and fermenting soybean milk, which is applied in the preparation of fermented soybean milk powder, fermented soybean milk powder and application fields, can solve the problems of oral flora imbalance, lack of fermented products, and limited, etc., and achieve good stability and significant inhibitory effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

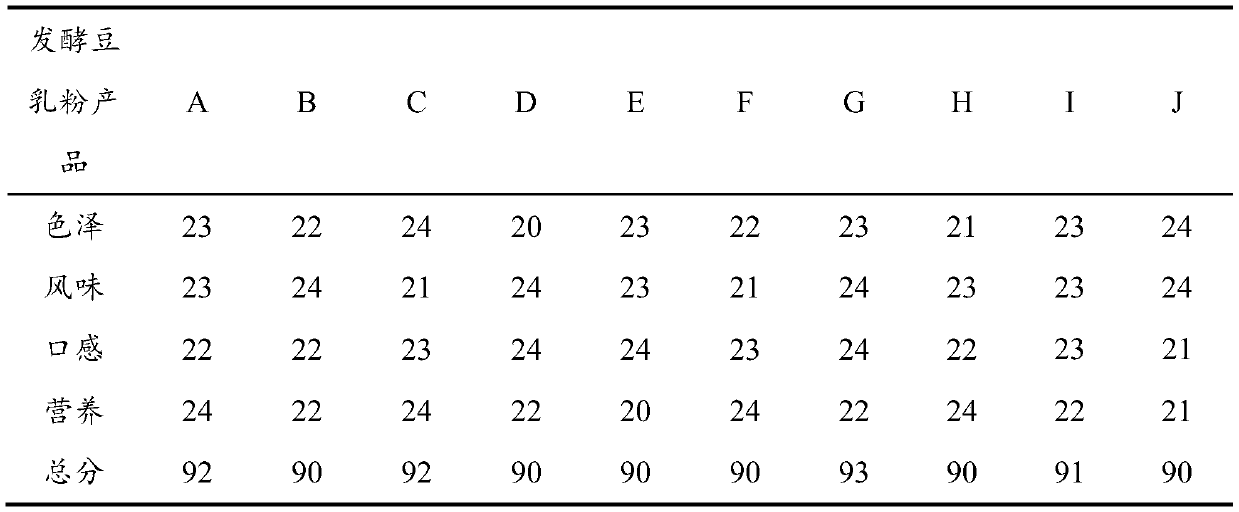

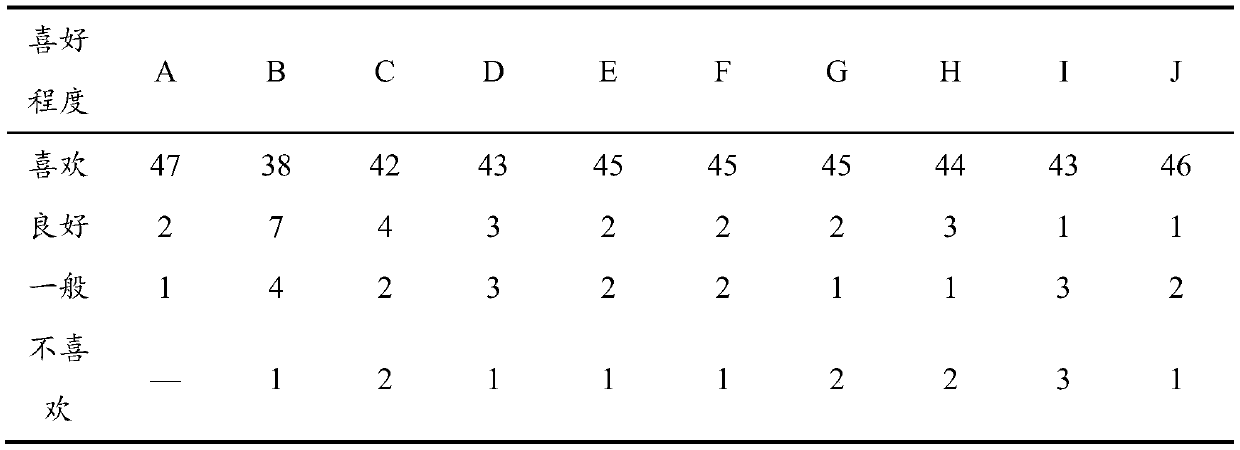

Examples

preparation example Construction

[0027] In a specific embodiment, a method for preparing fermented soybean milk powder is provided, comprising the following steps: inoculating Lactobacillus fermentum (Lactobacillus fermentum) CGMCC No.17321 in soybean milk for fermentation, and obtaining fermented soybean milk powder after freeze-drying .

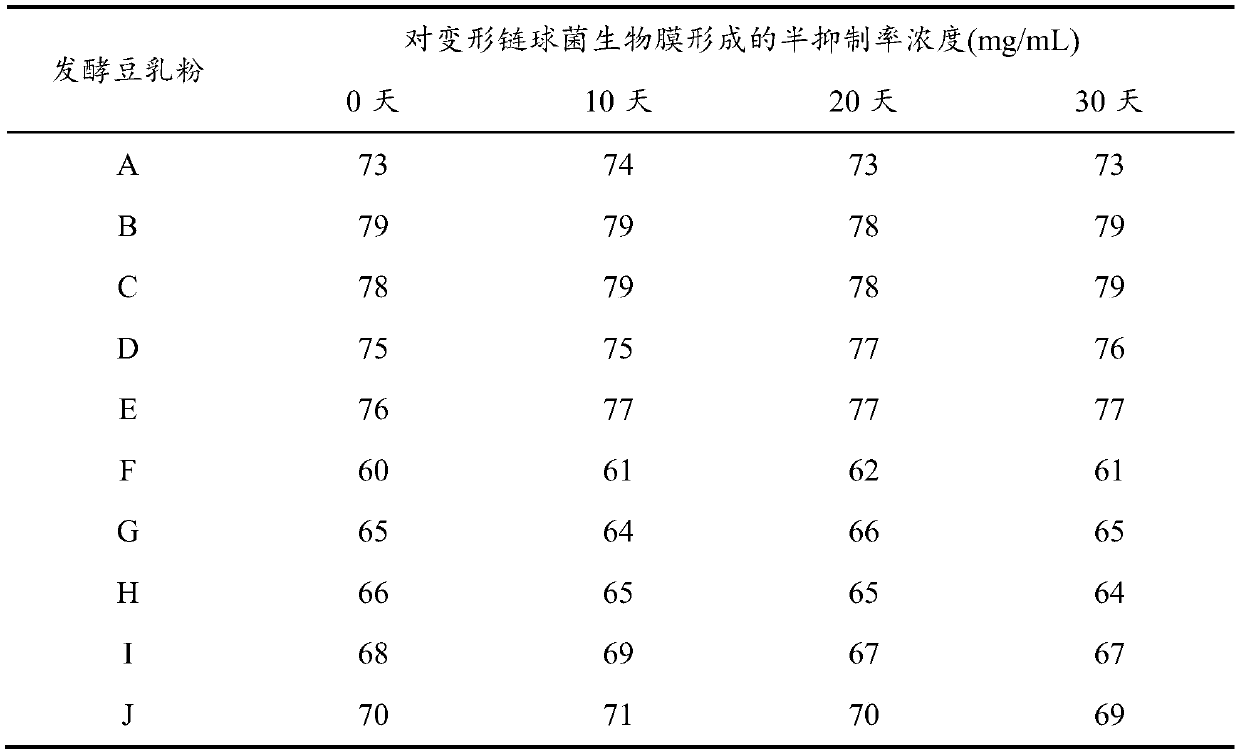

[0028]The preparation method in the above-mentioned technical scheme adopts Lactobacillus fermentum (Lactobacillus fermentum) CGMCC No.17321 for the first time, ferments with soybean milk as a medium, and prepares fermented soybean milk powder with Streptococcus mutans biofilm inhibitory activity, which discloses Lactobacillus fermentum ( Lactobacillus fermentum) CGMCC No.17321 fermented soybean milk powder has a new application of anti-caries. Compared with other strains that can produce fermented soybean milk powder, the fermented soybean milk powder prepared by CGMCC No.17321 has a more significant inhibitory effect on the formation of Streptococcus mutans biofilm, and ...

Embodiment 1

[0044] 1. Materials and methods

[0045] (a) Preparation of Lactobacillus fermentum seeds (fermentation strains): Dissolve the lyophilized powder of Lactobacillus fermentum CGMCC No.17321 with a small amount of sterile distilled water, and use an inoculation loop to take a ring and streak it on the MRS solid medium (Merck Co. Germany), take out after anaerobic culture at 37°C for 24 hours, pick a single colony with an inoculation loop and put it into 1mL MRS liquid (Merck Co. Germany), use a vortex shaker to evenly disperse the colony in the liquid medium, Take it out after 24 hours of anaerobic culture at 37°C, inoculate 50 mL of MRS liquid with 2% (v / v) inoculum, cultivate at 37°C for 24 hours, centrifuge the culture at 9,000 rpm for 10 minutes, discard the supernatant, and wash the bacteria with sterile distilled water After 2 times, suspend with sterile distilled water of the original culture volume to obtain seeds for fermentation, and the bacterial concentration of the s...

Embodiment 2

[0058] 1. Materials and methods

[0059] (a) Preparation of Lactobacillus fermentum seed (fermentation strain) and Streptococcus mutans bacterial suspension: Same as Example 1.

[0060] (b) Preparation of soymilk: After weighing the dried red bean, add five times the mass of water and soak at 37°C for 8 hours, discard the water, add a certain proportion of wet beans and water to the soymilk machine to obtain the desired Soybean milk with solid content was sterilized at 121°C for 20 minutes to obtain aseptic red bean soymilk with specified solid content.

[0061] (c) Determination of the inhibitory rate and IC50 of fermented soybean milk powder to Streptococcus mutans biofilm formation: Same as Example 1.

[0062] 2. Preparation of fermented soybean milk powder

[0063] Lactobacillus fermentum (Lactobacillus fermentum) CGMCC No.17321 was aseptically inoculated into red bean milk with a solid content of 9% (w / w) at an inoculum size of 1% (v / v), cultured at 15°C for 48 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com