Non-vacuum-state rolled titanium steel composite plate and preparation method thereof

A composite plate, non-vacuum technology, applied in metal rolling, chemical instruments and methods, manufacturing tools, etc., can solve the problems of non-green, environmentally friendly and sustainable production methods, explosion and composite method noise pollution, environmental pollution, and weather effects. and other problems, to achieve the effect of low requirements for workers and equipment, meeting standards and processing requirements, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

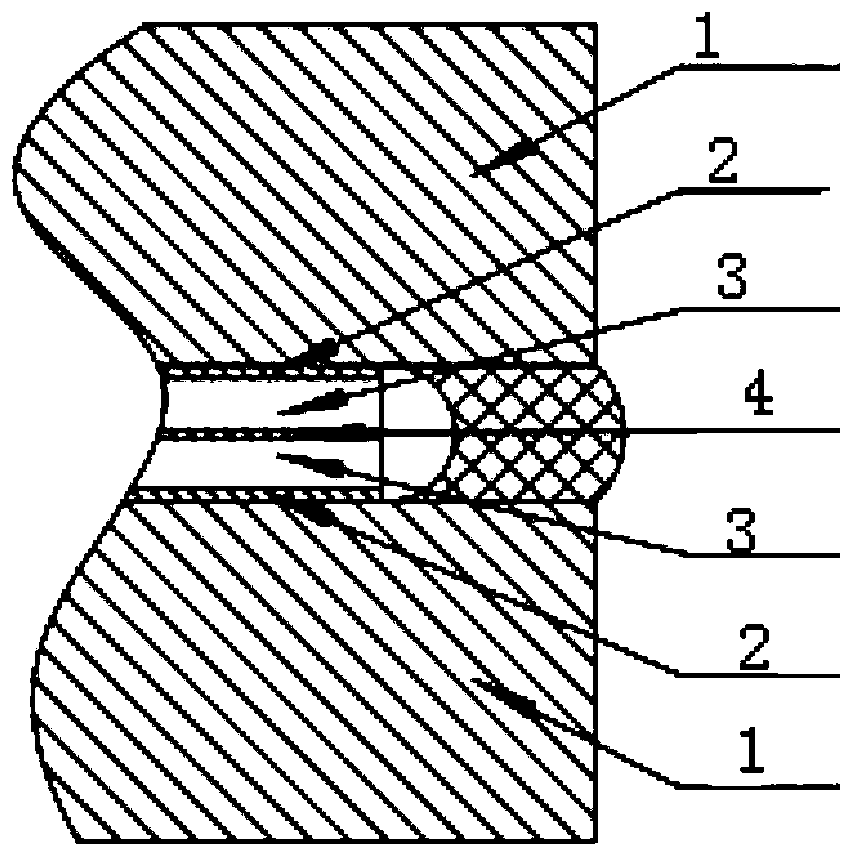

[0025] A method for preparing a non-vacuum rolling titanium-steel clad plate, the specific steps are as follows:

[0026] 1) Select a carbon steel plate with a thickness of 100mm, a transition layer with a thickness of 1.5mm and a titanium plate with a thickness of 10mm, cut the plate to the required size, and do surface treatment;

[0027] 2) To prepare a release agent, take alumina powder or magnesium oxide powder and organic matter powder with a mesh size greater than 40 and mix with water in a ratio of (2-3): (1-2): 100 and stir evenly, and apply it on the titanium plate The non-bonded surface of the product should be left to dry or placed in an oven for drying, and the temperature of the oven should not be higher than 180°C;

[0028] 3) Place the side of the titanium plate coated with the release agent opposite, and fix it by spot welding;

[0029] 4) Stack the carbon steel plate, transition layer and titanium plate in sequence, and the stacking order is: carbon steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com