Tetraphenylethylene-labeled responsive quaternized polyvinyl alcohol, and preparation method and application thereof

A technology for salinizing polyvinyl alcohol and tetraphenylethylene, which is applied in the field of tetraphenylethylene-labeled responsive quaternary ammonium salted polyvinyl alcohol and its preparation and application, to achieve excellent antibacterial performance, simple process operation, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

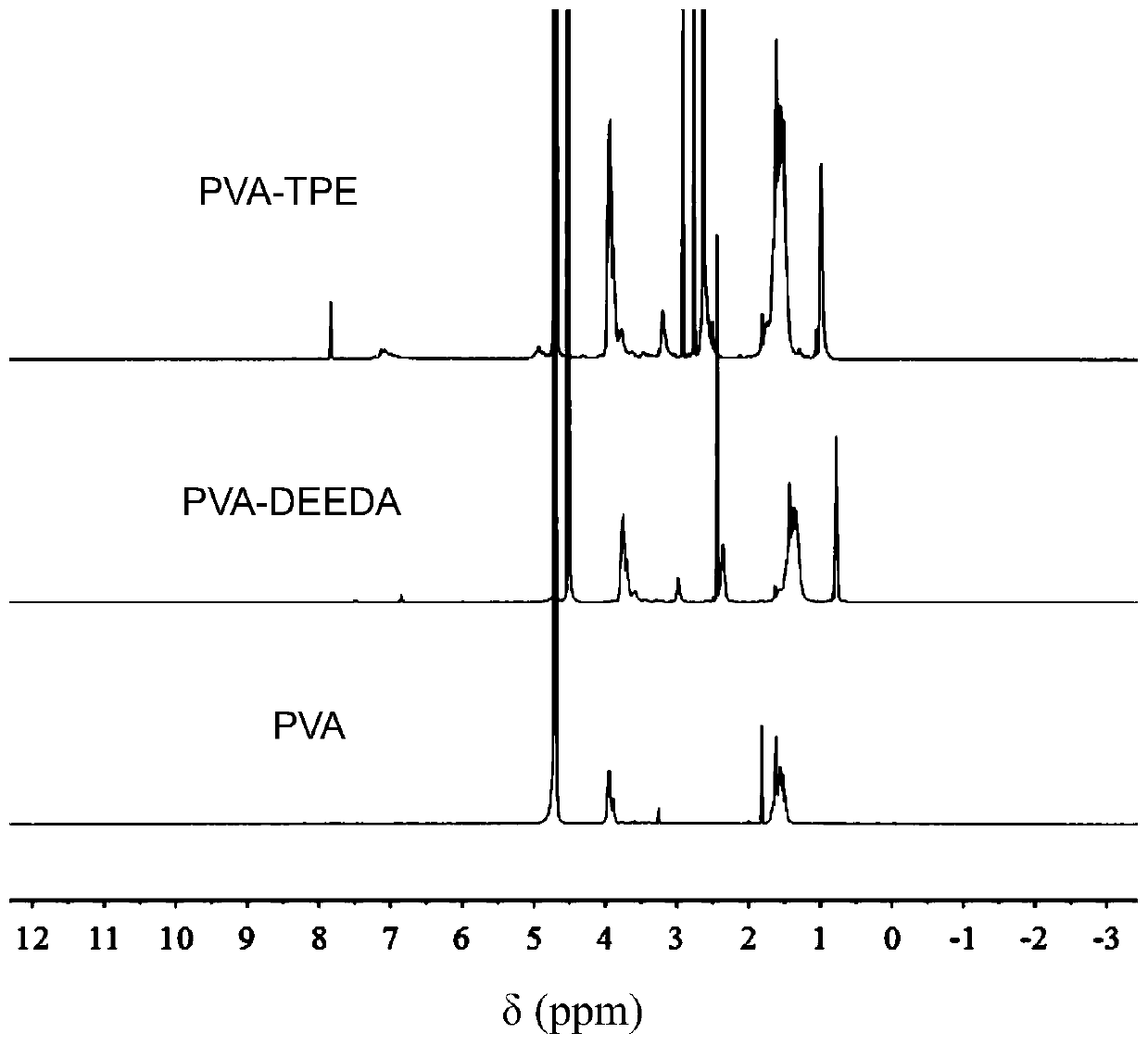

[0042] (1) Preparation of PVA-DEEDA: Polyvinyl alcohol (5.0 g, 0.12 mol of hydroxyl group) was dissolved in 100 mL of DMSO, stirred at 90° C. to dissolve. After completely dissolving, cool down to room temperature, add CDI (7.8g, 0.048mol) to the above solution for activation for 3 hours, then slowly add DEEDA (6.7mL, 0.048mol) to the above solution for 20 hours at 22°C. Add 50 mL of 25% ammonia solution and stir for 1 hour to remove unreacted CDI. Finish the reaction, precipitate in acetone, dissolve the precipitate in deionized water, dialyze for 3 days, and freeze-dry to obtain modified polyvinyl alcohol. The weight average molecular weight of polyvinyl alcohol is preferably 85,000 to 124,000.

[0043] (2) Preparation of PVA-TPE: PVA-DEEDA (600mg, 16.4mmol) obtained in step (1) was dissolved in 12mL DMSO, stirred until completely dissolved, and then TPE-CH 2 Br (35 mg, 0.082 mmol), heated at 70°C for 24 hours, precipitated with acetone, dissolved in deionized water, dialy...

Embodiment 2

[0052] (1) Preparation of PVA-DEEDA: Polyvinyl alcohol (5.0 g, 0.12 mol of hydroxyl group) was dissolved in 100 mL of DMSO, stirred at 90° C. to dissolve. After completely dissolving, cool down to room temperature, add CDI (9.2 g, 0.06 mol) to the above solution for activation for 3 hours, then slowly add DEEDA (8 mL, 0.06 mol) to the above solution for 20 hours at 22°C. Add 50 mL of 25% ammonia solution and stir for 1 hour to remove unreacted CDI. Finish the reaction, precipitate in acetone, dissolve the precipitate in deionized water, dialyze for 3 days, and freeze-dry to obtain modified polyvinyl alcohol. The weight average molecular weight of polyvinyl alcohol is preferably 85,000 to 124,000.

[0053] (2) Preparation of PVA-TPE: PVA-DEEDA (600mg, 16.4mmol) obtained in step (1) was dissolved in 12mL DMSO, stirred until completely dissolved, and then TPE-CH 2 Br (35 mg, 0.082 mmol), heated at 70°C for 24 hours, precipitated with acetone, dissolved in deionized water, dialy...

Embodiment 3

[0055] (1) Preparation of PVA-DEEDA: Polyvinyl alcohol (5.0 g, 0.12 mol of hydroxyl group) was dissolved in 100 mL of DMSO, stirred at 90° C. to dissolve. After completely dissolving, cool down to room temperature, add CDI (11.7g, 0.072mol) to the above solution for activation for 3 hours, then slowly add DEEDA (10mL, 0.072mol) to the above solution for 20 hours at 22°C. Add 50 mL of 25% ammonia solution and stir for 1 hour to remove unreacted CDI. Finish the reaction, precipitate in acetone, dissolve the precipitate in deionized water, dialyze for 3 days, and freeze-dry to obtain modified polyvinyl alcohol. The weight average molecular weight of polyvinyl alcohol is preferably 85,000 to 124,000.

[0056] (2) Preparation of PVA-TPE: PVA-DEEDA (600mg, 16.4mmol) obtained in step (1) was dissolved in 12mL DMSO, stirred until completely dissolved, and then TPE-CH 2 Br (35 mg, 0.082 mmol), heated at 70°C for 24 hours, precipitated with acetone, dissolved in deionized water, dialy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com