Polypropylene foaming material based on recycled plastic and preparation method thereof

A technology for foaming materials and recycling plastics, applied in the field of foaming materials, can solve the problems of high purity requirements and low recycling efficiency of recycled plastics, and achieve the effects of green insulation performance, improved recycling efficiency, and increased use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of the polypropylene foam material based on reclaimed plastics, and this preparation method comprises the following steps:

[0027] (1) Weigh 55-90% polypropylene by weight, 10-40% recycled plastic by weight, and 1-10% foaming agent by weight, mix them evenly, and then extrude and granulate Prepare expandable polypropylene particles; and preferably, in the polypropylene, the molar ratio of propylene is 60-95%;

[0028] and

[0029] (3) After the foamed polypropylene beads prepared in step (2) are steam-molded, a halogen-free flame-retardant polypropylene foam material is obtained.

[0030] Wherein, in the above step (1), the polypropylene is, for example, selected from at least one of propylene-ethylene binary random copolymers and propylene-ethylene-butylene terpolymers. The recycled plastic is at least one selected from waste polypropylene, waste polyethylene, waste polycarbonate, waste polyvinyl chloride, waste po...

Embodiment 1

[0040] Blend polypropylene, recycled polypropylene, talcum powder, and stabilizer into the twin-screw, according to the weight percentage, polypropylene 58%, recycled polypropylene 40%, talc powder 1%, stabilizer 1%, at 200 ° C Through twin-screw extrusion and cold water cutting to obtain blend particles, the particle diameter is 0.7-1.3 mm, the length is 1-1.6 mm, and the aspect ratio is 1.2-1.5.

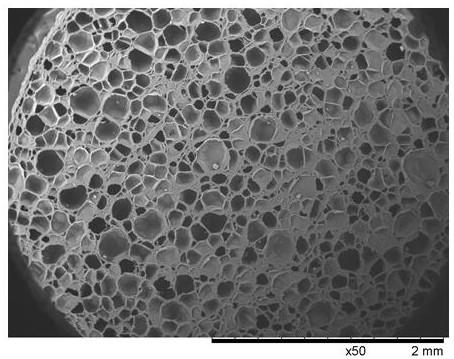

[0041] Put 2kg of blend particles, 20kg of water, 500g of pentane, 100g of montmorillonite, and 50g of calcium stearate into the reaction kettle, pass in carbon dioxide, heat to 120°C, maintain the pressure at 2.1MPa for 30 minutes, pass through the quick pressure relief valve, Unload the contents of the kettle to atmospheric pressure and dry to obtain 15 times expanded polypropylene beads with a density of 0.06 g / cm 3 ,in figure 1 It is a schematic diagram of the particle cross-section electron microscope picture of expanded polypropylene beads.

[0042]The dried expanded polypr...

Embodiment 2

[0045] Blending polypropylene, recycled polyethylene, zinc borate, and antioxidants into the twin-screw, according to the weight percentage, polypropylene 68%, recycled polyethylene 30%, zinc borate 1%, antioxidant 1%, at 190 ° C Through twin-screw extrusion and cold water cutting to obtain blend particles, the particle diameter is 0.7-1.3 mm, the length is 1-1.6 mm, and the aspect ratio is 1.2-1.5.

[0046] Put 2kg of blend particles, 20kg of water, 100g of organoclay, and 50g of sodium benzenesulfonate into the reactor, feed in carbon dioxide, heat to 130°C, maintain the pressure at 2.3MPa for 30 minutes, pass through the rapid pressure relief valve, and drain the reactor within 30s. The material is unloaded to atmospheric pressure and dried to obtain 20 times expanded polypropylene beads with a density of 0.045 g / cm 3 .

[0047] The dried expanded polypropylene beads were loaded in a pressure tank of 0.5 MPa for 12 hours, and the water vapor pressure was 0.25 MPa, and mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com