AGV visual navigation color zone and manufacturing method thereof

A visual navigation and ribbon technology, applied in the direction of adhesives, film/flake adhesives, etc., to achieve the effects of easy processing, good needle-punching resistance and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

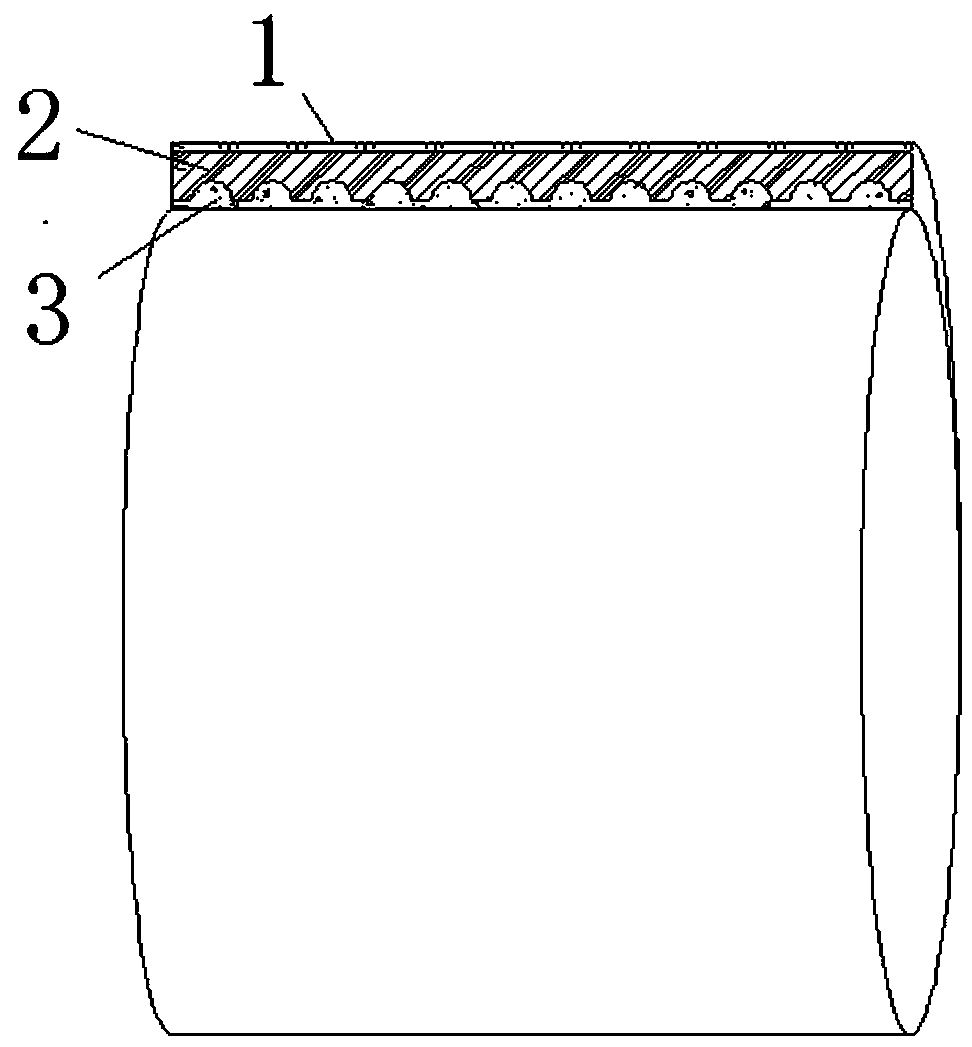

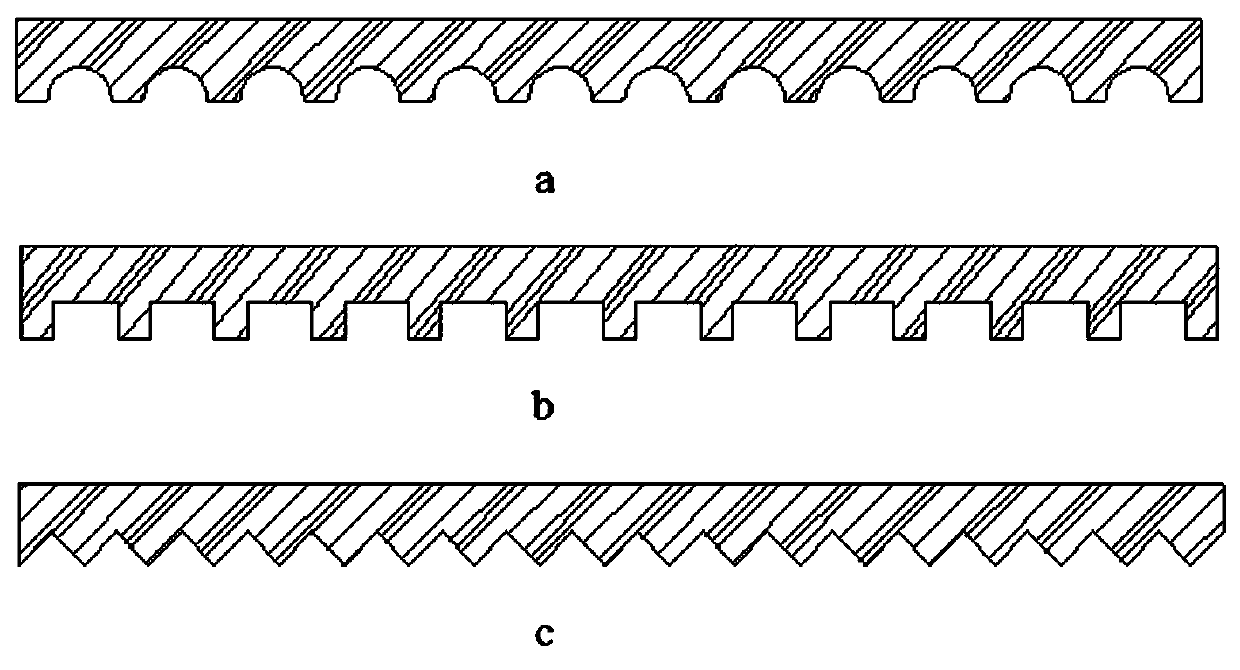

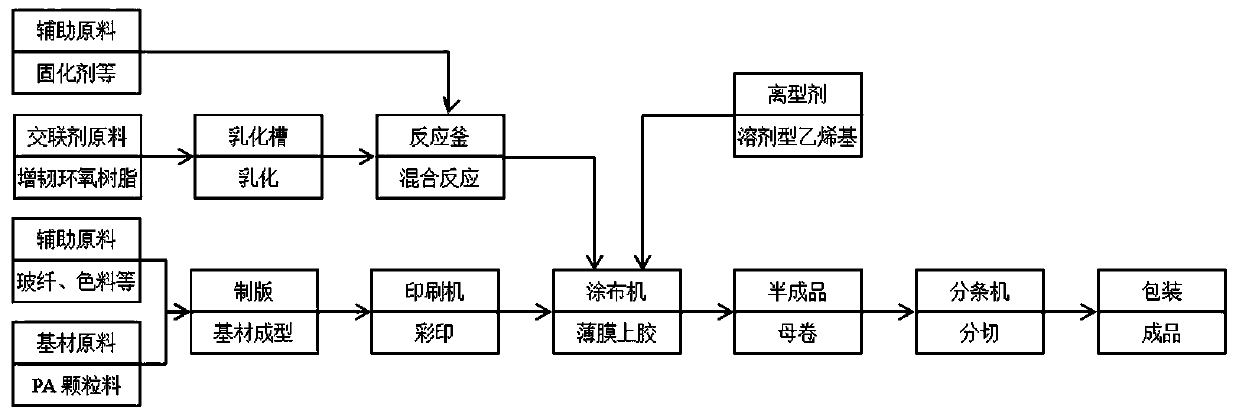

[0049] Add 30wt% glass fiber and use PA resin containing 50wt% PA66 as raw material to prepare a substrate with a width of 50mm and a thickness of 1mm. One side of the substrate is pressed figure 2 b Forming: Toughened epoxy resin and curing agent in a ratio of 4:1, adding diluent, accelerator, coupling agent and other auxiliary materials to make adhesive in a reactor.

[0050] The prepared base material was spread out and glued by a coating machine, the amount of release agent added was 0.1 g, and the thickness of the obtained adhesive layer was 20 um. After the adhesive layer and the release agent layer are completely cured, they are rolled, and the release force of the rolled ribbon is 20g.

[0051] After testing, the adhesive strength of the ribbon is 28MPa, and the T-peel strength is 50N / cm.

[0052] The ribbon can bond cement, metal, plastic, ceramics, hard rubber, wood, etc.

[0053] The ribbon has been repeatedly rolled over 10,000 times by a 5-ton forklift on the c...

Embodiment 2

[0055] Using PA resin without adding glass fiber and containing 80wt% PA6 as raw material, a substrate with a width of 30 mm and a thickness of 0.5 mm was prepared, and one side of the substrate was pressed figure 2 a Forming: Toughened epoxy resin and curing agent in a ratio of 6:1, adding diluent, accelerator, coupling agent and other auxiliary materials to make adhesive in a reactor.

[0056] The prepared base material was spread and glued by a coating machine, the amount of release agent added was 0.2 g, and the thickness of the obtained adhesive layer was 30 um. After the adhesive layer and the release agent layer are completely cured, they are rolled, and the release force of the rolled ribbon is 10g.

[0057] Tested and tested, the adhesive strength of the ribbon is 25MPa, and the T-peel strength reaches 60N / cm.

[0058] The ribbon can bond cement, metal, plastic, ceramics, hard rubber, wood, etc.

[0059] The ribbon has been repeatedly rolled over 10,000 times by a ...

Embodiment 3

[0061] Using PA resin with 20wt% glass fiber and 60wt% PA66 / PA6 as raw material, a substrate with a width of 40mm and a thickness of 0.1mm was used, and one side of the substrate was pressed figure 2 c Forming: Toughened epoxy resin and curing agent in a ratio of 8:1, adding diluent, accelerator, coupling agent and other auxiliary materials to make adhesive in a reactor.

[0062] The prepared base material was spread and glued by a coating machine, the amount of release agent added was 0.08g, and the thickness of the obtained adhesive layer was 50um. After the adhesive layer and the release agent layer are completely cured, the ribbon is rolled, and the release force of the rolled ribbon is 28g.

[0063] After testing, the adhesive strength of the ribbon is 25MPa, and the T-peel strength is 56N / cm.

[0064] The ribbon can bond cement, metal, plastic, ceramics, hard rubber, wood, etc.

[0065] The ribbon has been repeatedly rolled over 10,000 times by a 5-ton forklift on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com