Method for preparing high-foamability egg albumen powder through cooperative modification of enzymolysis and fermentation

A technology of synergistic fermentation and egg white powder, applied to bacteria used in food preparation, food ingredients as odor improvers, sugary food ingredients, etc., can solve the problem of the disappearance of the functional properties of egg white, the inability to solve the fishy smell of egg white, and the failure to exert microorganisms, etc. problems, to achieve the effect of facilitating human digestion and absorption, easy digestion and absorption of human body, and degradation of allergic ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

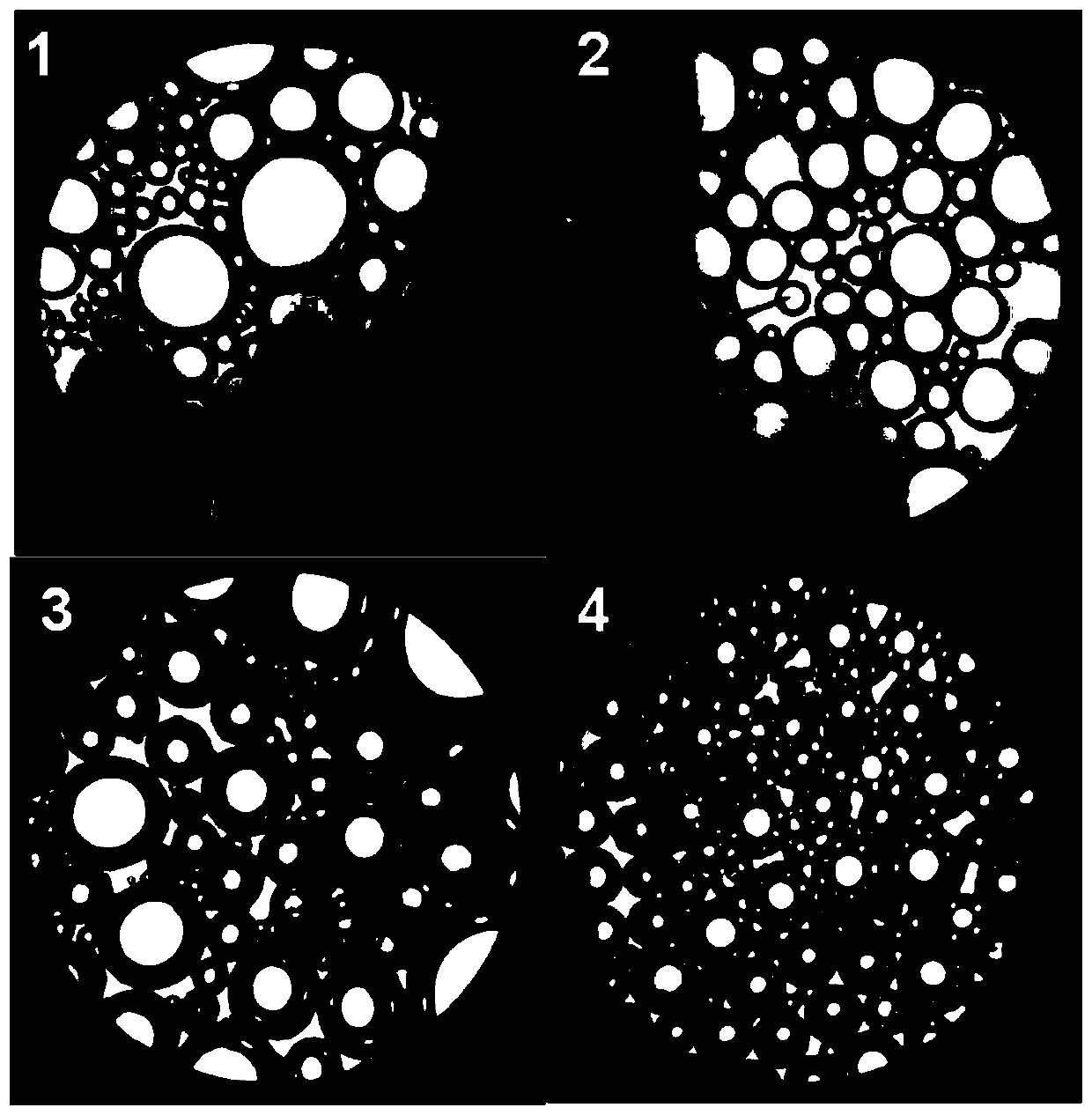

Image

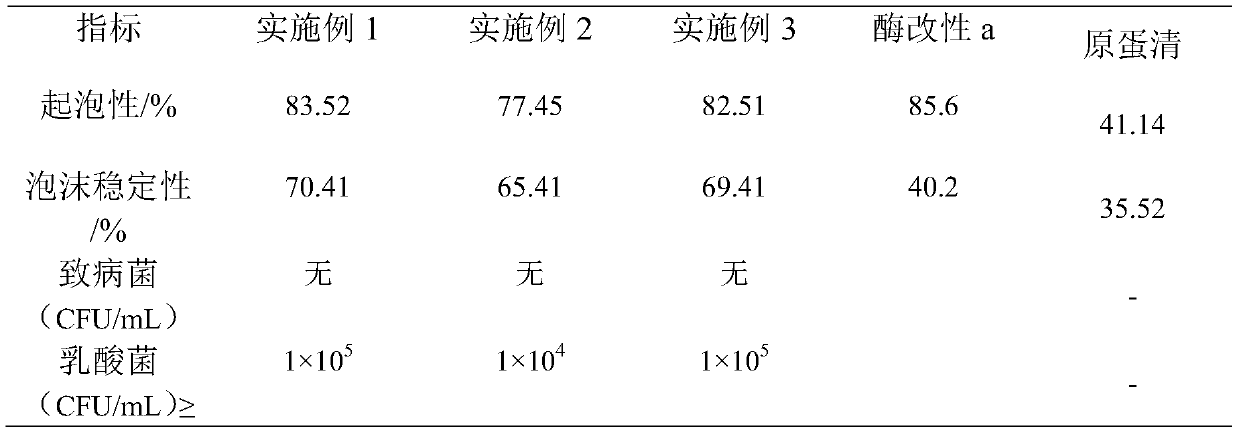

Examples

Embodiment 1

[0031] A process for preparing high-foaming egg white powder through enzymatic hydrolysis and collaborative fermentation modification, specifically comprising the following steps:

[0032] 1) Raw material preparation: select fresh eggs, use an egg separator to separate the egg whites, carefully remove the frenulum to obtain fresh egg white liquid, add 50% (accounting for the mass ratio of the diluted mixed liquid) distilled water or ionized water to dilute to obtain the mixed liquid;

[0033] 2) Homogenization: Take the mixed solution and homogenize it at a homogenization pressure of 30MPa and a homogenization temperature of 55°C;

[0034] 3) Filtration: the mixed solution after taking the homogeneous solution is filtered through a 60-mesh sieve to obtain the filtrate;

[0035] 4) Enzymolysis: the filtrate was enzymolyzed for 105 minutes at a temperature of 50° C. with 5% enzyme added, and the enzyme was selected from subtilisin, papain and bromelain;

[0036] 5) Enzyme inact...

Embodiment 2

[0042] A process for preparing high-foaming egg white powder through enzymatic hydrolysis and collaborative fermentation modification, specifically comprising the following steps:

[0043] 1) Raw material preparation: select fresh eggs, use an egg separator to separate the egg whites, carefully remove the frenulum to obtain fresh egg white liquid, add 50% (accounting for the mass ratio of the diluted mixed liquid) distilled water or ionized water to dilute to obtain the mixed liquid;

[0044] 2) Homogenization: Take the mixed solution and homogenize it at a homogenization pressure of 30MPa and a homogenization temperature of 65°C;

[0045] 3) Filtration: the mixed solution after taking the homogeneous solution is filtered through a 30-mesh sieve to obtain the filtrate;

[0046]4) Enzymolysis: take the filtrate and add 10% of the enzyme amount, and enzymolyze it for 105 minutes at a temperature of 55° C., and the enzyme is selected from subtilisin, alkaline protease and papain;...

Embodiment 3

[0053] A process for preparing high-foaming egg white powder through enzymatic hydrolysis and collaborative fermentation modification, specifically comprising the following steps:

[0054] 1) Raw material preparation: select fresh eggs, use an egg separator to separate the egg whites, carefully remove the frenulum to obtain fresh egg white liquid, add 40% (accounting for the mass ratio of the diluted mixed liquid) distilled water or ionized water to dilute to obtain the mixed liquid;

[0055] 2) Homogenization: Take the mixed solution and homogenize it at a homogenization pressure of 30MPa and a homogenization temperature of 55°C;

[0056] 3) Filtration: the mixed solution after taking the homogeneous solution is filtered through a 60-mesh sieve to obtain the filtrate;

[0057] 4) Enzymolysis: take the filtrate and add 10% of the enzyme amount, and enzymolyze it for 105 minutes at a temperature of 55° C., and the enzyme is selected from subtilisin, alkaline protease and bromel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com