Method for treating wastewater containing impregnating agent

A treatment method and wetting agent technology, which are applied in the field of wastewater treatment containing wetting agents, can solve problems such as failure to meet environmental protection standards, low biodegradability, and complex wastewater components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

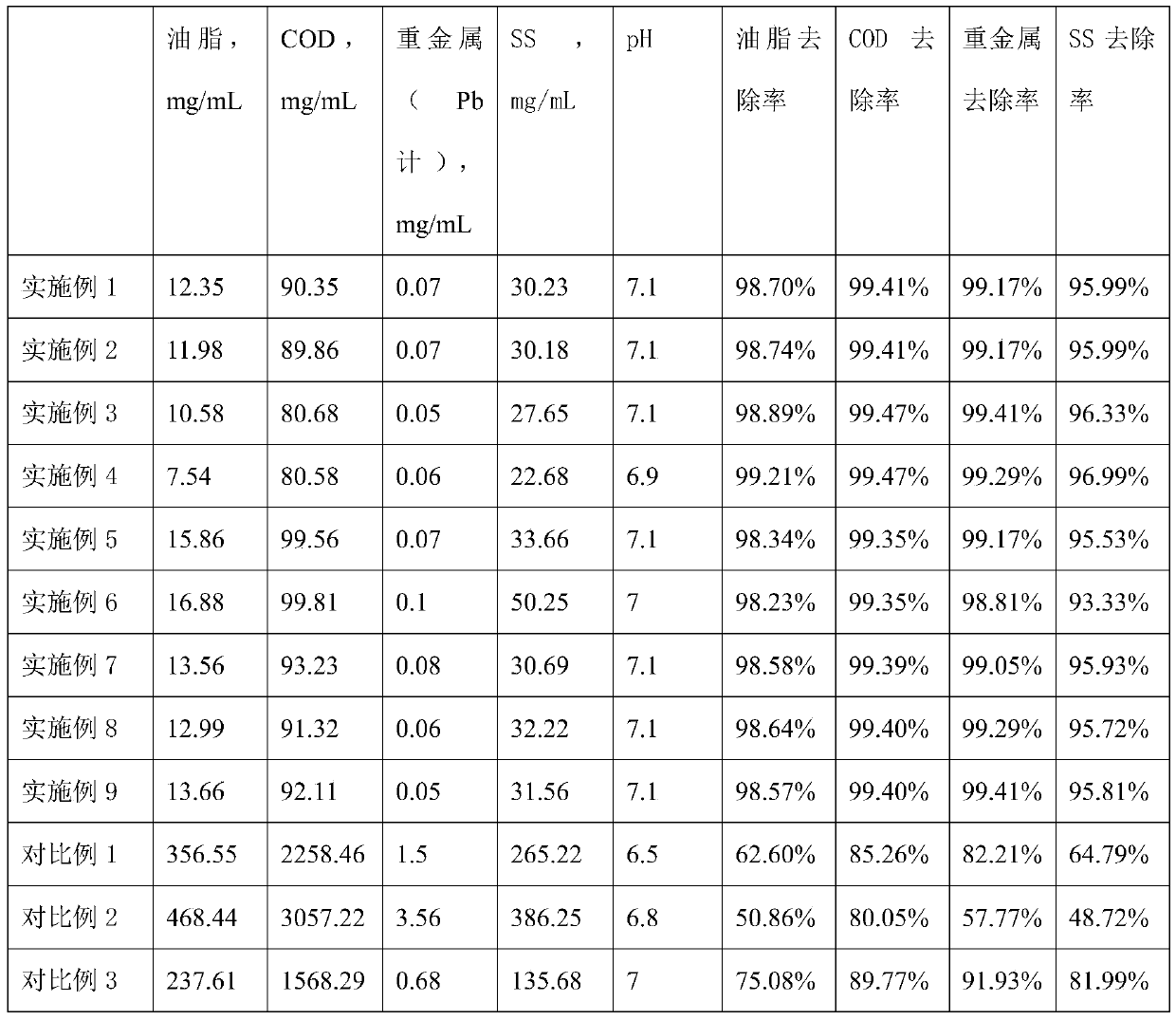

[0028] Present embodiment uses waste water composition to see table 1

[0029] Table 1

[0030] project Fat, mg / mL COD, mg / mL Heavy metal (Pb), mg / mL SS, mg / mL pH concentration 953.37 15326.58 8.43 753.22 7.1

[0031] Wastewater treatment methods are as follows:

[0032] (1) Put 100kg of waste water containing wetting agent into the insulated reaction kettle, stir, and the stirring speed is 100-150r / min;

[0033] (2) Direct current is used to energize the waste water containing wetting agent, the anode material is iron, the cathode material is graphite, and the voltage is 15V;

[0034] (3) Add NaOH in the reactor, stir well, make pH between 8.8-9.0;

[0035] (4) Add 1 kg of polyacrylamide to the reaction kettle, and after half a minute, add 2 kg of potassium aluminum sulfate dodecahydrate, stir for 0.5 min, and the stirring speed is 200-300 r / min. After stirring, the detected pH is 7.2, which meets the requirements;

[0036] (5) Add 5kg of ...

Embodiment 2-3

[0039] The difference from Example 1 is that the voltages in step (2) are 22V and 30V respectively.

Embodiment 4

[0041] The difference from Example 1 is that the amount of polyacrylamide added in step (4) is 1.67 kg, and the amount of potassium aluminum sulfate dodecahydrate added is 3.34 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com