Degradable mulching film for vegetable cultivation in plateau regions and preparation method and application of mulching film

A technology for degrading mulch and vegetables, applied in the field of materials, can solve the problems of blocking nutrients, destroying the quality of cultivated land, and dead seedlings of vegetables, and achieves good mechanical properties and aging resistance, enhanced mechanical properties, and improved aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

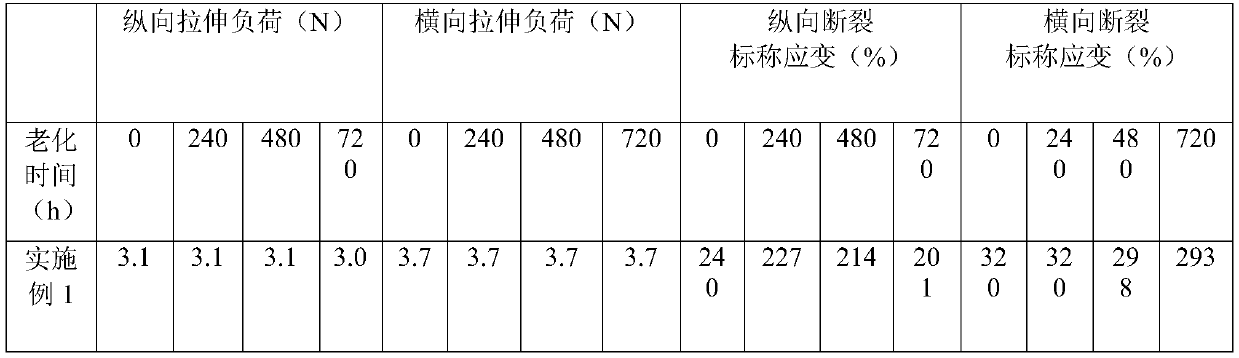

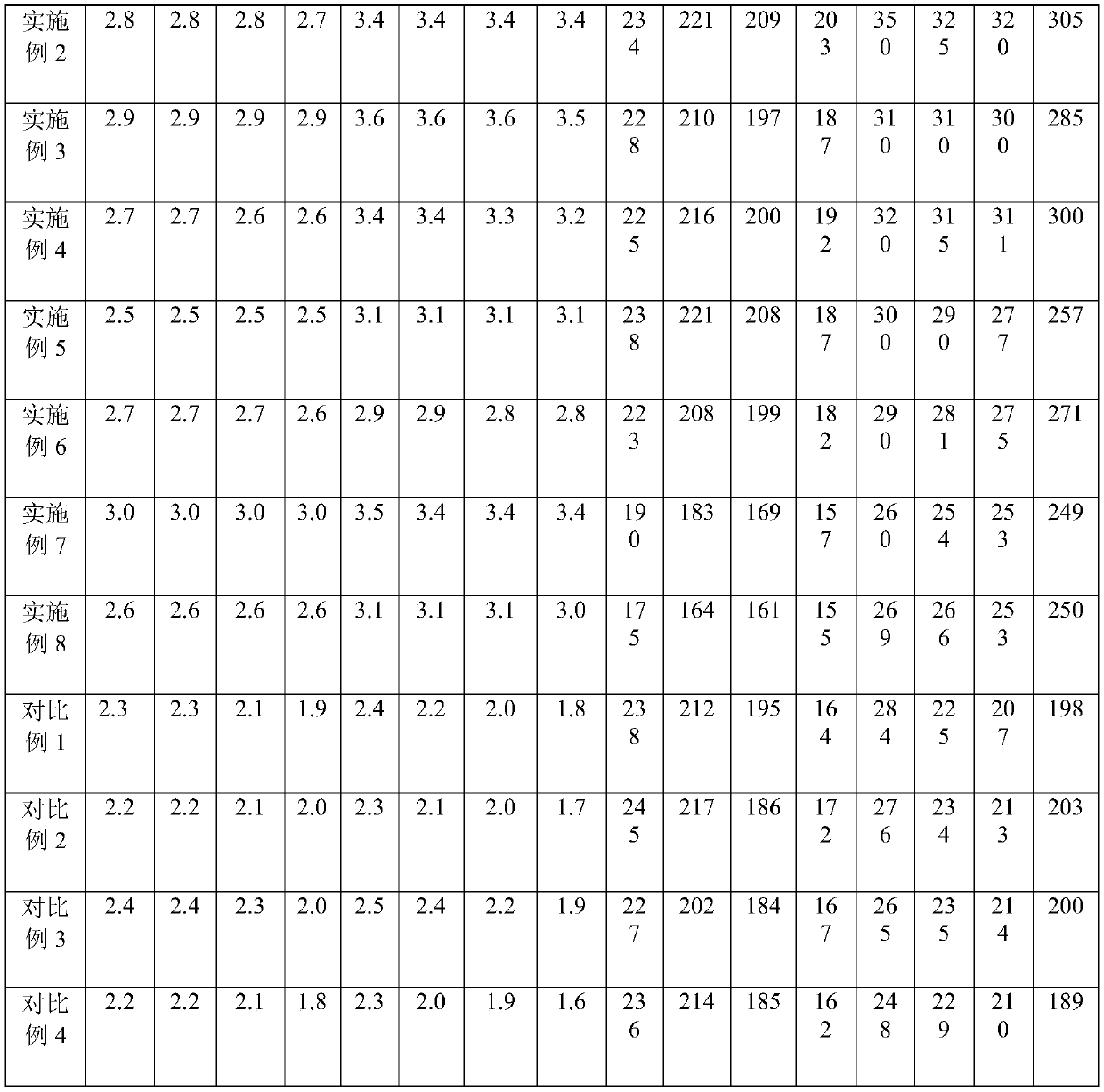

Examples

Embodiment 1

[0020] Example 1 proposes a special material for fully biodegradable mulch film for plateau vegetable planting and its preparation method, which specifically includes:

[0021] PBAT, molecular weight 120,000, 100 parts.

[0022] PLA, molecular weight 80,000, 10 parts.

[0023] Compatibilizer 4370, 0.5 parts.

[0024] calcium carbonate, 8 servings.

[0025] Loaded ultraviolet absorber a, 0.5 parts.

[0027] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0028] The preparation method includes the following steps: put PBAT and PLA in an oven at 60°C, and dry them for 6 hours; put the loaded ultraviolet absorber a, zinc oxide, antioxidant 168, and antioxidant 1010 in a stirrer, and put them in a stirrer for 100r / min and stir for 2 hours; then add 4370 and calcium carbonate to the high mixer for mixing at a speed of 1000r / min and mix for 2 minutes. Then the mixed material is put into a screw extruder for extrusion granulation, and th...

Embodiment 2

[0031] Example 2 proposes a special material for fully biodegradable mulch film for plateau vegetable planting and its preparation method, which specifically includes:

[0032] PBAT, molecular weight 120,000, 100 parts.

[0033] PLA, molecular weight 80,000, 10 parts.

[0034] Compatibilizer 4370, 0.5 parts.

[0035] calcium carbonate, 8 servings.

[0036] Loaded ultraviolet absorber b, 0.5 parts.

[0037] Zinc oxide, 0.3 parts.

[0038] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0039] The preparation method includes the following steps: put PBAT and PLA in an oven at 60°C, and dry them for 6 hours; put the loaded ultraviolet absorber b, zinc oxide, antioxidant 168, and antioxidant 1010 in a stirrer, and put them in a stirrer for 100r / min and stir for 2 hours; then add 4370 and calcium carbonate to the high mixer for mixing at a speed of 1000 rpm, and mix for 2 minutes. Then the mixed material is put into a screw extruder for extrusion granulation, and th...

Embodiment 3

[0042] Example 3 proposes a fully biodegradable mulch special material for plateau vegetable planting and a preparation method thereof, specifically comprising:

[0043] PBAT, molecular weight 120,000, 100 parts.

[0044] PLA, molecular weight 80,000, 10 parts.

[0045] Compatibilizer 4370, 0.5 parts.

[0046] calcium carbonate, 8 servings.

[0047] Loaded ultraviolet absorber c, 0.5 part.

[0048] Zinc oxide, 0.3 parts.

[0049] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0050] The preparation method includes the following steps: put PBAT and PLA in an oven at 60°C, and dry them for 6 hours; put the loaded ultraviolet absorber c, zinc oxide, antioxidant 168, and antioxidant 1010 in a stirrer, and put them in a stirrer for 100r / min and stir for 2 hours; then add 4370 and calcium carbonate to the high mixer for mixing at a speed of 1000 rpm, and mix for 2 minutes. Then the mixed material is put into a screw extruder for extrusion granulation, and the melt t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com