Oriented conductive collagen hydrogel, biomimetic conductive nerve scaffold material and preparation method of oriented conductive collagen hydrogel and biomimetic conductive nerve scaffold material

A scaffold material and conductive glue technology, applied in the fields of biomedical materials and biomedical engineering, can solve the problems of limited cell adhesion sites, poor compatibility, and difficult to achieve conductive hydrogels, and achieve the promotion of elongation and nerve related problems. Functional expression, good biocompatibility, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

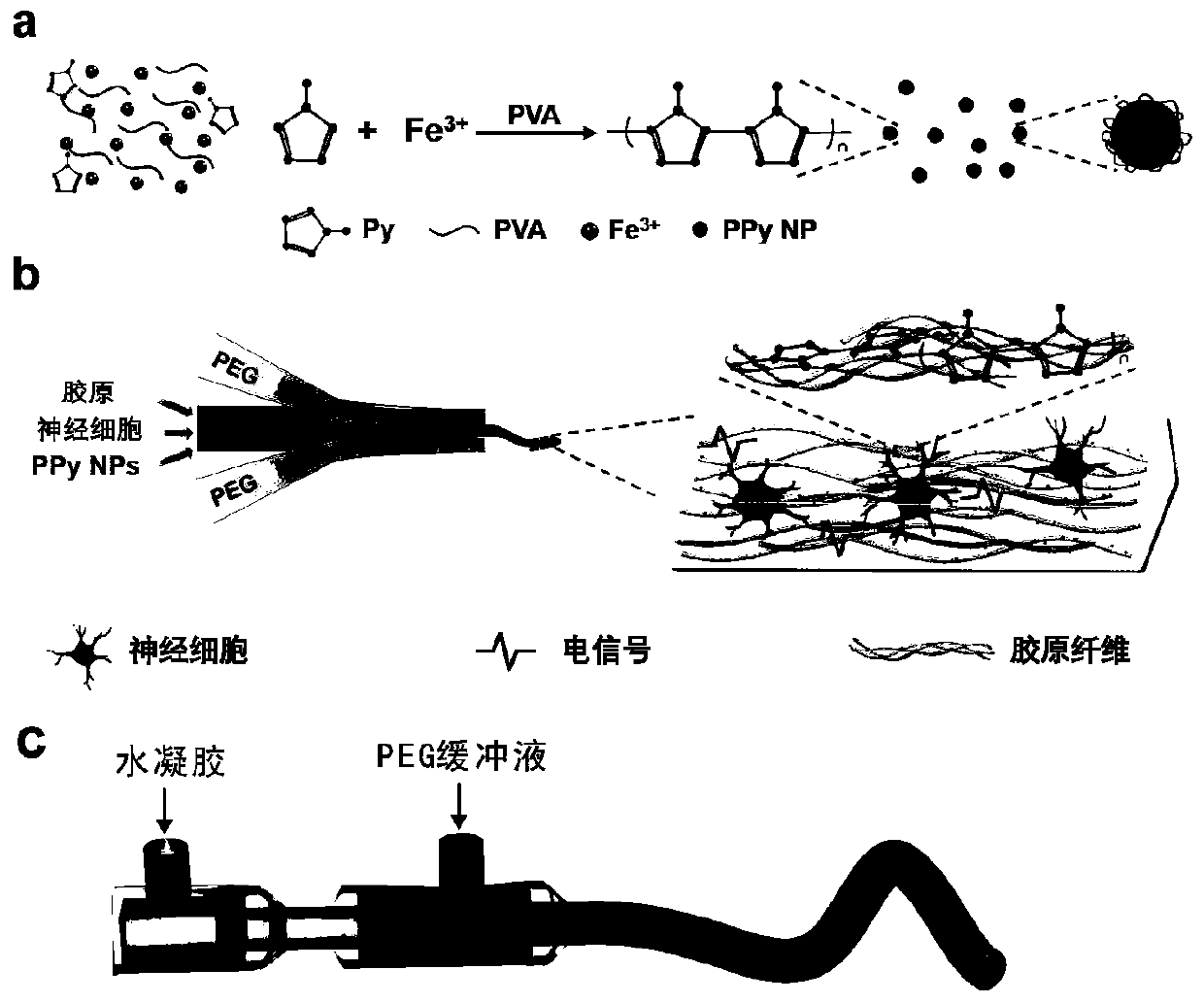

[0046] The steps of preparing the oriented conductive collagen hydrogel in this embodiment are as follows:

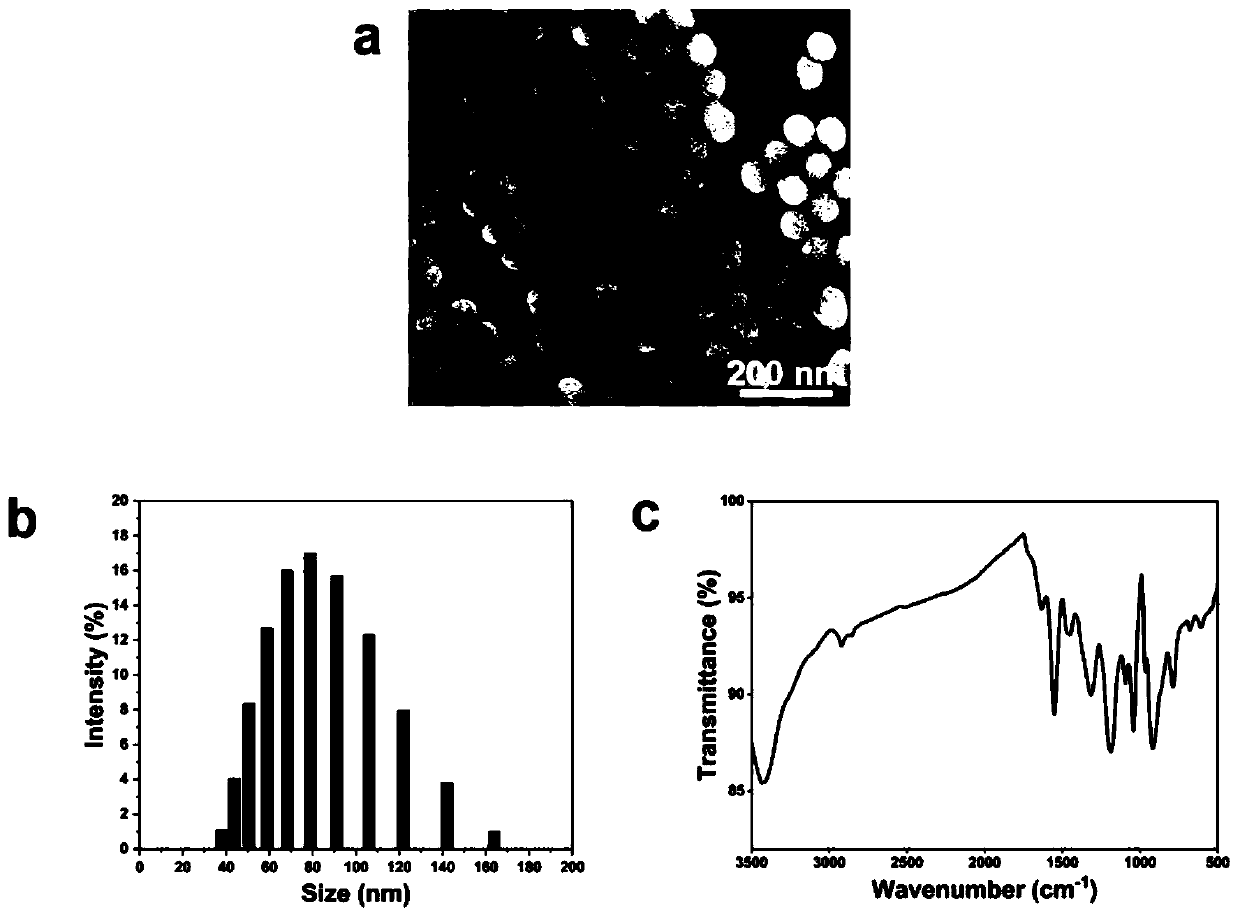

[0047] (1) Preparation of PPy nanoparticles

[0048] Disperse 1.5g of PVA (molecular weight: 31000) in 20mL of deionized water, and then place it in a 60°C oven and heat it for 30min to accelerate its dispersion to obtain the first dispersion, then take it out and cool it to room temperature. Then 1.2434g oxidant FeCl 3 ·6H 2 O was added to the first dispersion, stirred until the oxidant was fully dispersed, and then left to stand for 1h to obtain FeCl 3 A second dispersion with a concentration of 0.23 mol / L. Then, under stirring conditions at 5°C, 140 μL of the conductive monomer Py was added dropwise to the second dispersion (Py concentration was 0.1 mol / L), and then the stirring reaction was continued at 5°C for 4 hours, and then deionized water was used to remove the conductive monomer by centrifugal washing. For soluble impurities, determine the concentration o...

Embodiment 2

[0054] The steps of preparing the oriented conductive collagen hydrogel in this embodiment are as follows:

[0055] (1) Preparation of PPy nanoparticles

[0056] Disperse 1.5g of PVA (molecular weight: 31000) in 20mL of deionized water, and then place it in a 60°C oven and heat it for 30min to accelerate its dispersion to obtain the first dispersion, then take it out and cool it to room temperature. Then 1.2434g oxidant FeCl 3 ·6H 2 O was added to the first dispersion, stirred until the oxidant was fully dispersed, and then left to stand for 1h to obtain FeCl 3 A second dispersion with a concentration of 0.23 mol / L. Then, under stirring conditions at 5°C, 140 μL of the conductive monomer Py was added dropwise to the second dispersion (Py concentration was 0.1 mol / L), and then the stirring reaction was continued at 5°C for 4 hours, and then deionized water was used to remove the conductive monomer by centrifugal washing. For soluble impurities, determine the concentration o...

Embodiment 3

[0062] The steps of preparing the oriented conductive collagen hydrogel in this embodiment are as follows:

[0063] (1) Preparation of PPy nanoparticles

[0064] Disperse 1.5g of PVA (molecular weight: 31000) in 20mL of deionized water, and then place it in a 60°C oven and heat it for 30min to accelerate its dispersion to obtain the first dispersion, then take it out and cool it to room temperature. Then 1.2434g oxidant FeCl 3 ·6H 2 O was added to the first dispersion, stirred until the oxidant was fully dispersed, and then left to stand for 1h to obtain FeCl 3 A second dispersion with a concentration of 0.23 mol / L. Then, under stirring conditions at 5°C, 140 μL of the conductive monomer Py was added dropwise to the second dispersion (Py concentration was 0.1 mol / L), and then the stirring reaction was continued at 5°C for 4 hours, and then deionized water was used to remove the conductive monomer by centrifugal washing. For soluble impurities, determine the concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com