Zinc oxide/carbon quantum dot composite photocatalyst, preparation method and application thereof

A technology of carbon quantum dots and zinc oxide, applied in the field of photocatalyst, zinc oxide/carbon quantum dot composite photocatalyst and its preparation, can solve the problems of poor reusability, low photocatalytic efficiency and high production cost, and achieve low cost, Good photodegradation effect, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

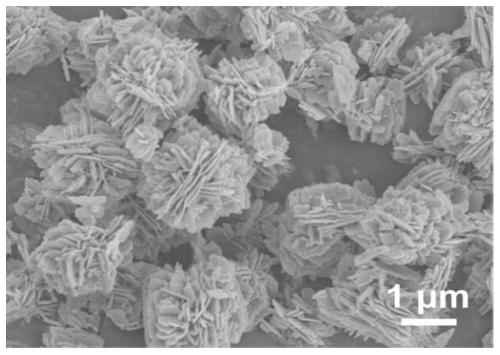

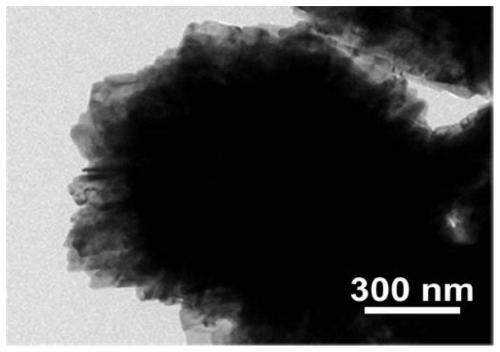

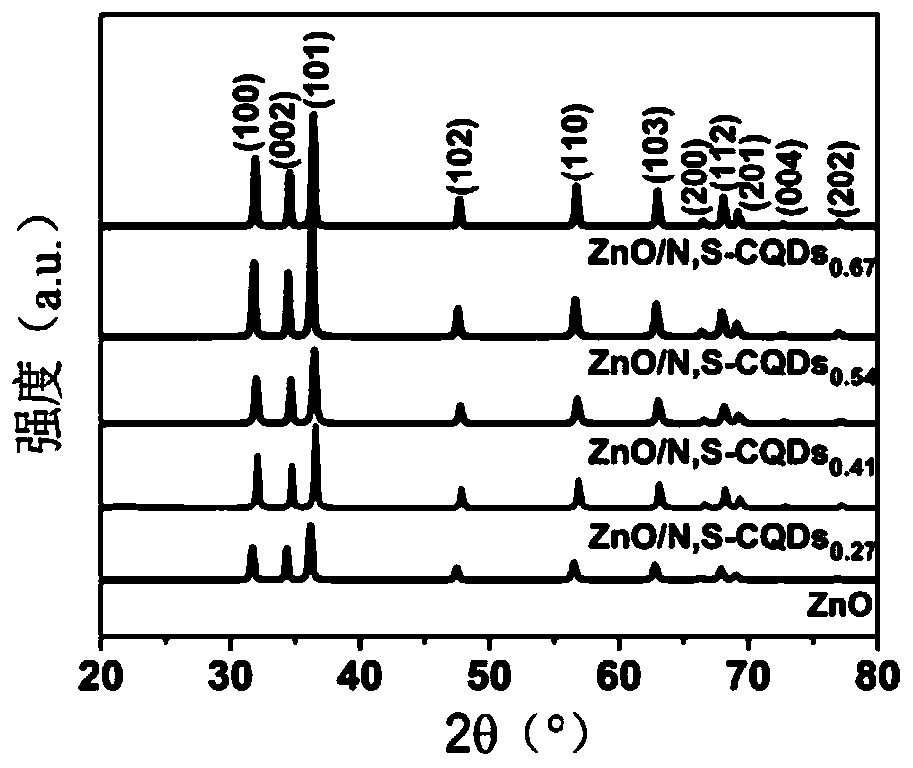

Image

Examples

Embodiment 1

[0057] A kind of zinc oxide / carbon quantum dot composite photocatalyst is prepared according to the following method:

[0058] 1) Add 6.25mL HNO 3 (Its mass fraction is 68wt.%) and 9.00mL ethylene glycol are simultaneously added to 4.75mL deionized water and mixed to obtain a mixed solution a;

[0059] 2) Add 1.5g of L-cysteine to 20mL of the mixed solution a obtained in step 1, stir at 600rpm for 10min, and obtain the mixed solution b after mixing evenly, transfer the mixed solution b to a hydrothermal reaction kettle for water Heat reaction, react at 180°C for 10h, after the reaction, cool the product to room temperature (25°C), centrifuge (10000rpm, 1h) to remove undispersed solids, and further dialyze the supernatant (MWCO 3500) to remove carbon quantum dots ( N, S-CQDs) impurities in the sample to obtain a mixed solution c, the pH of the mixed solution c is 3.80;

[0060] 3) Prepare zinc nitrate with a concentration of 0.0089 g / mL in 75 mL of deionized water, and add ...

Embodiment 2

[0067] A kind of zinc oxide / carbon quantum dot composite photocatalyst is prepared according to the following method:

[0068] 1) Add 6.25mL HNO 3 (Its mass fraction is 68wt.%) and 9.00mL ethylene glycol are simultaneously added to 4.75mL deionized water and mixed to obtain a mixed solution a;

[0069] 2) Add 1.5g of L-cysteine to 20mL of the mixed solution a obtained in step 1, stir at 600rpm for 10min, and obtain the mixed solution b after mixing evenly, transfer the mixed solution b to a hydrothermal reaction kettle for water Heat reaction, react at 180°C for 10h, after the reaction, cool the product to room temperature (25°C), centrifuge (10000rpm, 1h) to remove undispersed solids, and further dialyze the supernatant (MWCO 3500) to remove carbon quantum dots ( N, S-CQDs) impurities in the sample to obtain a mixed solution c, the pH of the mixed solution c is 3.80;

[0070] 3) Prepare zinc nitrate with a concentration of 0.0089 g / mL in 75 mL of deionized water, and add ...

Embodiment 3

[0077] A kind of zinc oxide / carbon quantum dot composite photocatalyst is prepared according to the following method:

[0078] 1) Add 6.25mL HNO 3 (Its mass fraction is 68wt.%) and 9.00mL ethylene glycol are simultaneously added to 4.75mL deionized water and mixed to obtain a mixed solution a;

[0079] 2) Add 1.5g of L-cysteine to 20mL of the mixed solution a obtained in step 1, stir at 600rpm for 10min, and obtain the mixed solution b after mixing evenly, transfer the mixed solution b to a hydrothermal reaction kettle for water Heat reaction, react at 180°C for 10h, after the reaction, cool the product to room temperature (25°C), centrifuge (10000rpm, 1h) to remove undispersed solids, and further dialyze the supernatant (MWCO 3500) to remove carbon quantum dots ( N, S-CQDs) impurities in the sample to obtain a mixed solution c, the pH of the mixed solution c is 3.80;

[0080] 3) Prepare zinc nitrate with a concentration of 0.0089 g / mL in 75 mL of deionized water, and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com