On-line purification method of hydrochloric acid in the production of potassium sulfate by Mannheim process

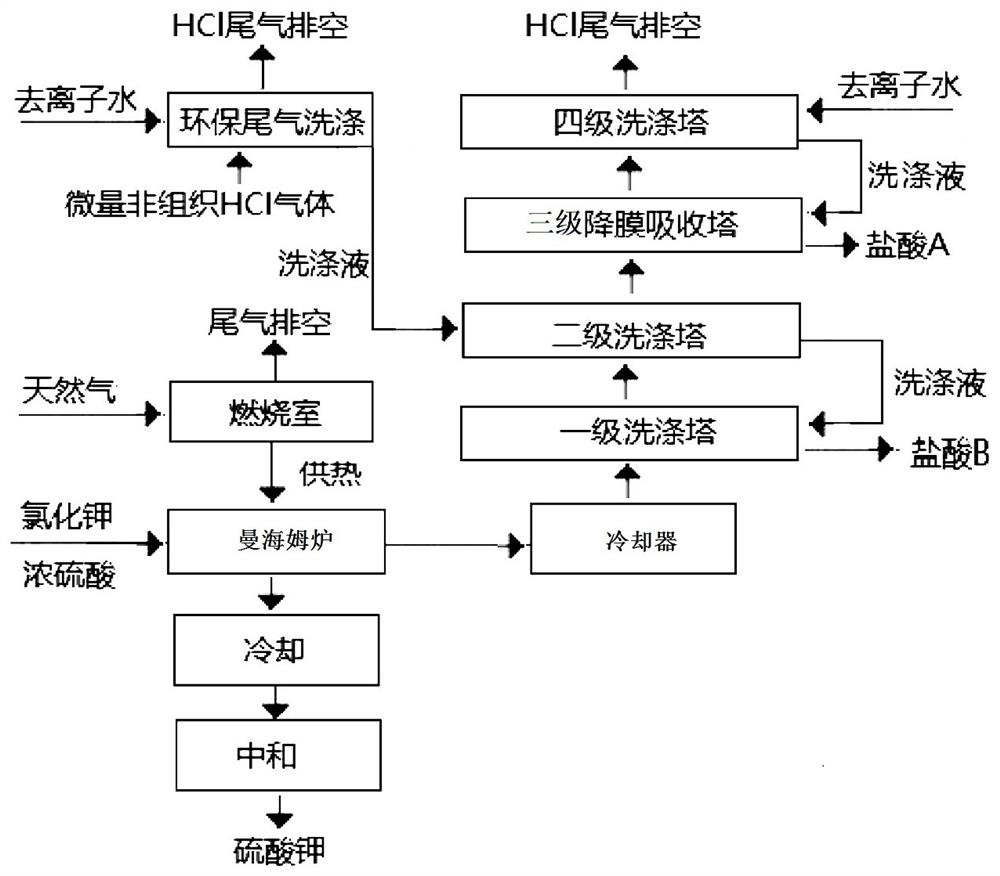

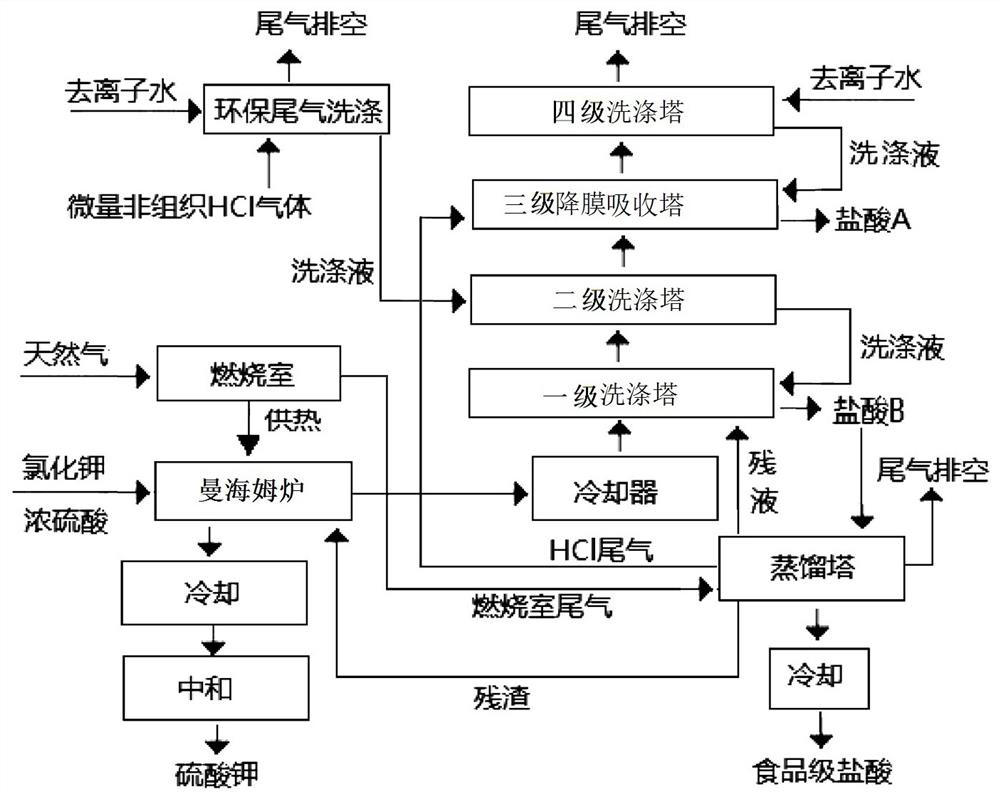

A Mannheim method, potassium sulfate technology, applied in the direction of sulfate/bisulfate preparation, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high impurity content of hydrochloric acid, economic loss of enterprises, low quality, etc., and achieve hydrochloric acid Good quality, no energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

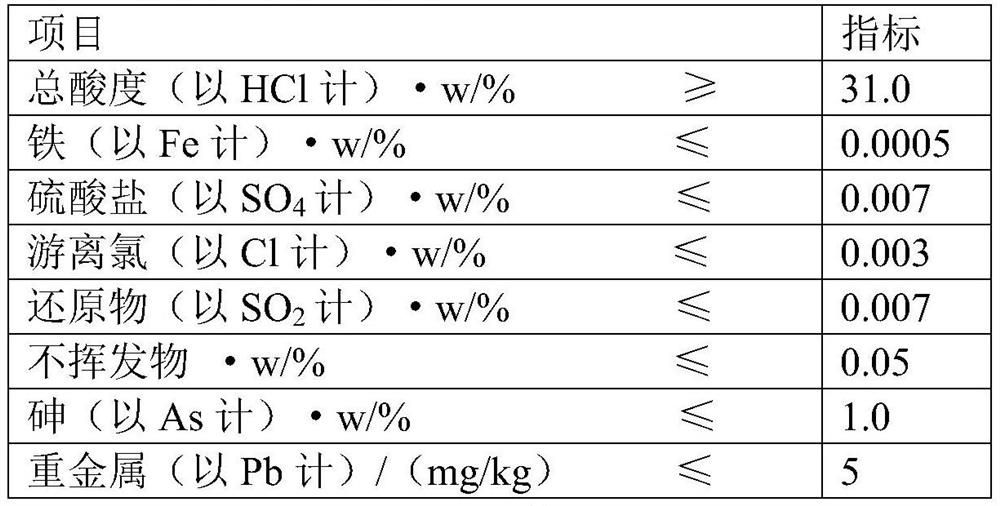

[0040] The hydrochloric acid B in the first-stage washing tower was pumped into the hydrochloric acid distillation column (flow rate was 14.16L / min), and introduced into the hydrochloric acid distillation tower at 245°C and the flow rate was 10m. 3 / s of combustion chamber exhaust for distillation. The flow rate of the residual liquid entering the primary washing tower is 7.08L / min, and the leaching liquid is condensed into the acid storage tank to obtain food-grade hydrochloric acid. Food-grade hydrochloric acid has clear color, sulfate content of 0.002%, iron salt content of 0.0005%, acid concentration of 32.7%, and an output of 15 tons / day.

[0041] Deionized water (flow rate of 9.44L / min) washes the hydrogen chloride gas in the four-stage washing tower, enters the three-stage falling film absorption tower to absorb the hydrogen chloride gas, and the hydrogen chloride tail gas generated in the distillation tower also directly enters the three-stage falling film absorption to...

Embodiment 2

[0044] The hydrochloric acid B in the first-stage washing tower was drawn into the hydrochloric acid distillation column (flow rate was 14.16L / min), and was introduced into the hydrochloric acid distillation tower at 295°C and the flow rate was 14m. 3 / s of combustion chamber exhaust for distillation. The flow rate of the residual liquid entering the first-level washing tower is 3.54L / min, and the leaching liquid is condensed into the acid storage tank to obtain food-grade hydrochloric acid. Food grade hydrochloric acid is clear in color, sulfate content is 0.001%, iron salt content has no clear value, acid concentration is 33.6%, and the output is 10 tons / day.

[0045] Deionized water (flow rate of 11.80L / min) washes the hydrogen chloride gas in the four-stage washing tower, and enters the three-stage falling film absorption tower to absorb the hydrogen chloride gas, and the hydrogen chloride tail gas generated in the distillation tower also directly enters the three-stage fa...

Embodiment 3

[0048] The hydrochloric acid B in the first-stage washing tower was drawn into the hydrochloric acid distillation column (flow rate was 9.44L / min), and was introduced into the hydrochloric acid distillation tower at 260°C and the flow rate was 13.7m. 3 / s of combustion chamber exhaust for distillation. The flow rate of the residual liquid entering the first-stage washing tower is 3.14L / min, and the leachate is condensed into the acid storage tank to obtain food-grade hydrochloric acid. Food-grade hydrochloric acid has clear color, sulfate content of 0.001%, iron salt content of 0.0005%, acid concentration of 32.1%, and an output of 13.3 tons / day.

[0049] Deionized water (flow rate of 10.24L / min) washes the hydrogen chloride gas in the four-stage washing tower, and enters the three-stage falling film absorption tower to absorb the hydrogen chloride gas, and the hydrogen chloride tail gas generated in the distillation tower also directly enters the three-stage falling film abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com