General preparation method for reduced graphene oxide-based composite film

A graphene-based composite film technology, applied in the direction of graphene, carbon nanotubes, nano-carbon, etc., can solve the problems of poor flexibility or stability of graphene-based composite films, and limit the potential application range of graphene-based composite films. Achieve the effects of perfect crystal structure, adjustable crispness and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

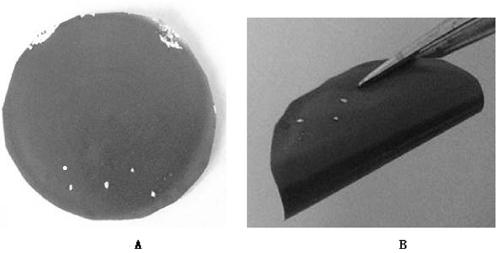

Image

Examples

Embodiment 1

[0032] Step (1): Disperse 0.5 g of graphene oxide in 100 mL of water, stir for 8 h, and sonicate for 20 min to obtain a 5 mg / mL graphene oxide dispersion;

[0033] Step (2): Dissolve 1 g of polyvinyl alcohol in 100 mL of water to prepare a 10 mg / mL polyvinyl alcohol solution;

[0034] Step (3): Take 0.5 mL of the graphene oxide dispersion prepared in step (1) and 1 mL of the polyvinyl alcohol solution prepared in step (2) and redisperse them in 200 mL of water to prepare graphene oxide / polyvinyl alcohol mixed solution;

[0035] Step (4): The graphene oxide / polyvinyl alcohol mixed solution prepared in step (3) is suction-filtered on an organic membrane with a diameter of about 4 cm to form a graphene oxide / polyvinyl alcohol mixed solution composite membrane.

[0036] Step (5): After putting the graphene oxide / polyvinyl alcohol composite film prepared in step (4) into the polytetrafluoroethylene lining, add 1 mL of water, seal it and put it into the reactor, and then seal it P...

Embodiment 2

[0039] Step (1): Disperse 1 g of graphene oxide in 200 mL of water, stir for 10 h, and sonicate for 5 min to obtain a graphene oxide dispersion;

[0040] Step (2): Add 0.01 g of carbon nanotubes, 10 mL of ethylenediamine and 5 g of sodium ascorbate to the graphene oxide dispersion obtained in step (1), stir for 1 h, and sonicate for 10 min, then take out 0.2 mL and dilute to 100 mL of water was filtered on an organic membrane with a diameter of about 4 mm after ultrasonication for 5 min to prepare a graphene oxide / carbon nanotube composite membrane.

[0041] Step (3): Put the graphene oxide / carbon nanotube composite film prepared in step (2) into a 150 mL polytetrafluoroethylene liner, add 1 mL of water, 1 mL of ethanol and 0.1 mL of ethylene glycol After the mixed solution is sealed, put the lining of the reactor into the reactor, and put it into 130 o The solvothermal reduction reaction was carried out in a C oven for 10 h to obtain the reduced graphene oxide / carbon nanotub...

Embodiment 3

[0044] Step (1): Disperse 1 g of graphene oxide in 200 mL of water, stir for 10 h, and sonicate for 10 min to obtain a graphene oxide dispersion;

[0045]Step (2): Take 5 mL of the graphene oxide dispersion obtained in step (1) and 2 mL of ethanol in a 10 mL glass bottle, stir for 10 min, then add 0.5 mL of tetrabutyl titanate (belonging to the aforementioned Precursor of inorganic nanomaterials), stirred for 30 minutes and then ultrasonicated for 2 minutes, to filter it into a graphene oxide-based composite membrane.

[0046] Step (3): Put the graphene oxide-based composite membrane in step (2) into the polytetrafluoroethylene lining, add 1 mL of water and seal it, then put it into the reactor and seal it, put the reactor into Into 150 o The hydrothermal reaction was carried out in a vacuum oven for 12 h to obtain the reduced graphene oxide / titanium dioxide composite film.

[0047] The reduced graphene oxide / titanium dioxide composite film obtained by the method has photoca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com