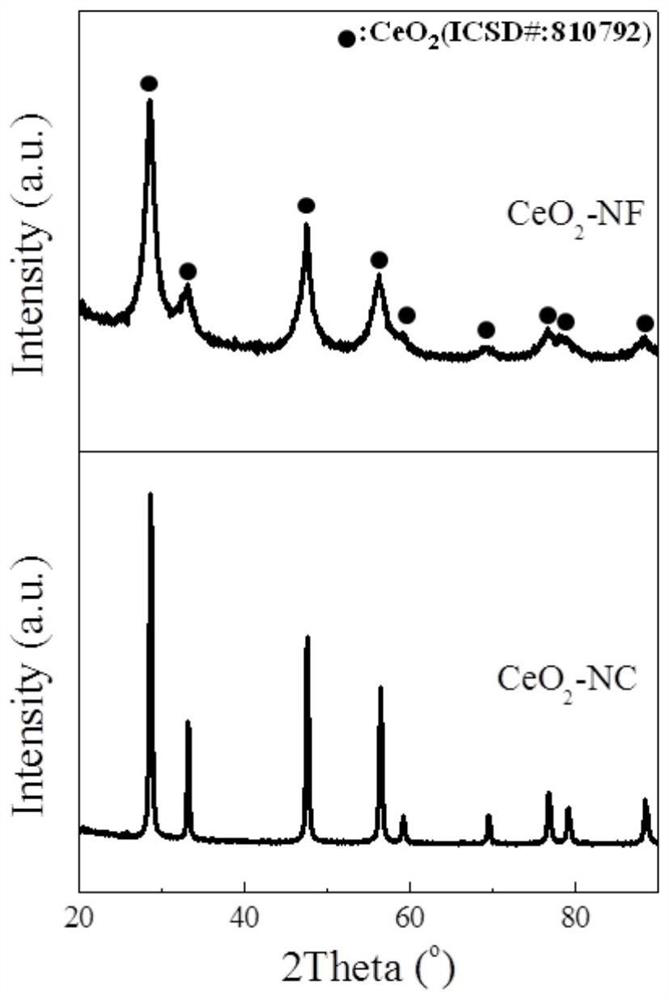

A control method of oxygen vacancy concentration in single crystal ceria

A cerium dioxide oxygen concentration technology, applied in cerium oxide/cerium hydroxide, chemical instruments and methods, lanthanide oxide/hydroxide, etc., can solve problems such as environmental hazards, increased cost, and complex process flow , to achieve the effect of simple and easy preparation method and avoiding disordered growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

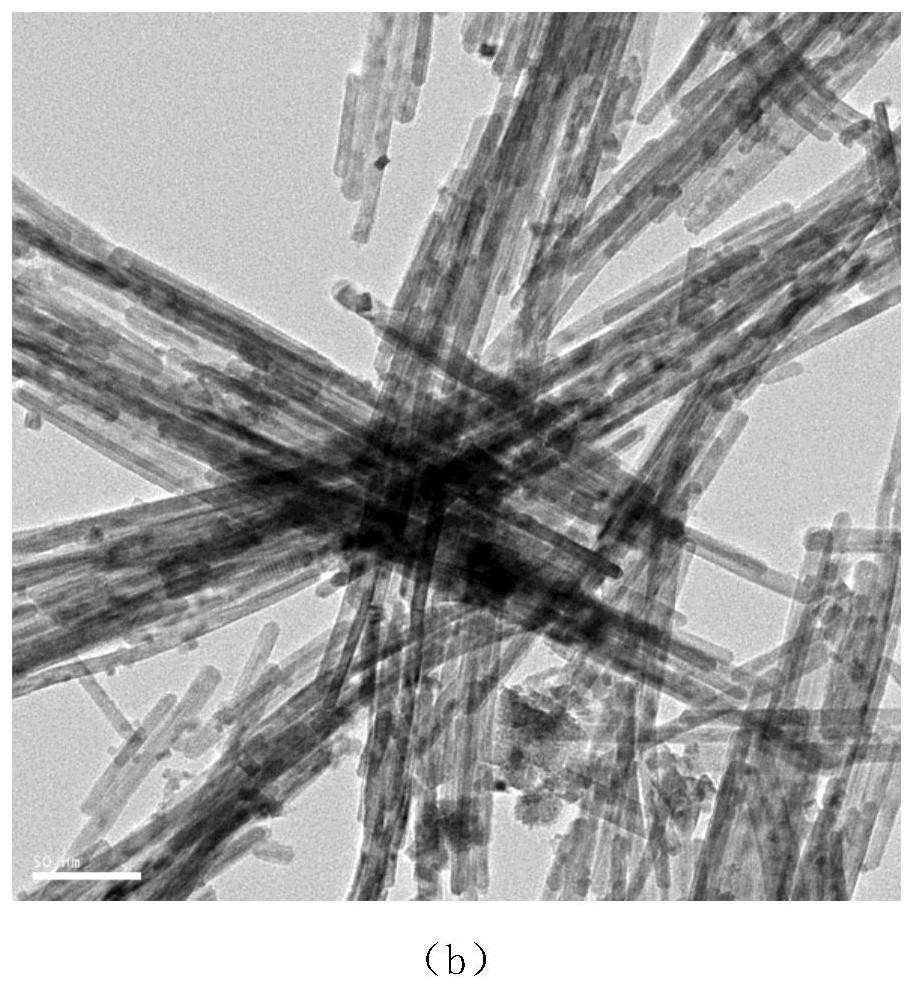

Embodiment 1

[0031] Take 1.736 kg of cerium nitrate and add it to 10 L of deionized water, and take 2.4 kg of sodium hydroxide and add it to 10 L of deionized water. After completely dissolving, add the two into two storage tanks for later use. Add 10L of pure water to a 40L volume reactor, seal and heat to 125°C, when the pressure inside the kettle is about 0.2MPa, pressurize the two storage tanks until the pressure is greater than 0.2MPa, and open the switch between the storage tank and the reactor valve, inject the reaction feed liquid of cerium salt and alkali into the reaction tank. Seal the reaction tank, stir at a speed of 100 rpm, set the hydrothermal reaction temperature of the reaction tank at 130° C., carry out the hydrothermal reaction, and stop the reaction after 48 hours. After cooling to room temperature, the pressure was released, and the reaction product mixture was subjected to solid-liquid separation, washed three times with deionized water, and washed three times with e...

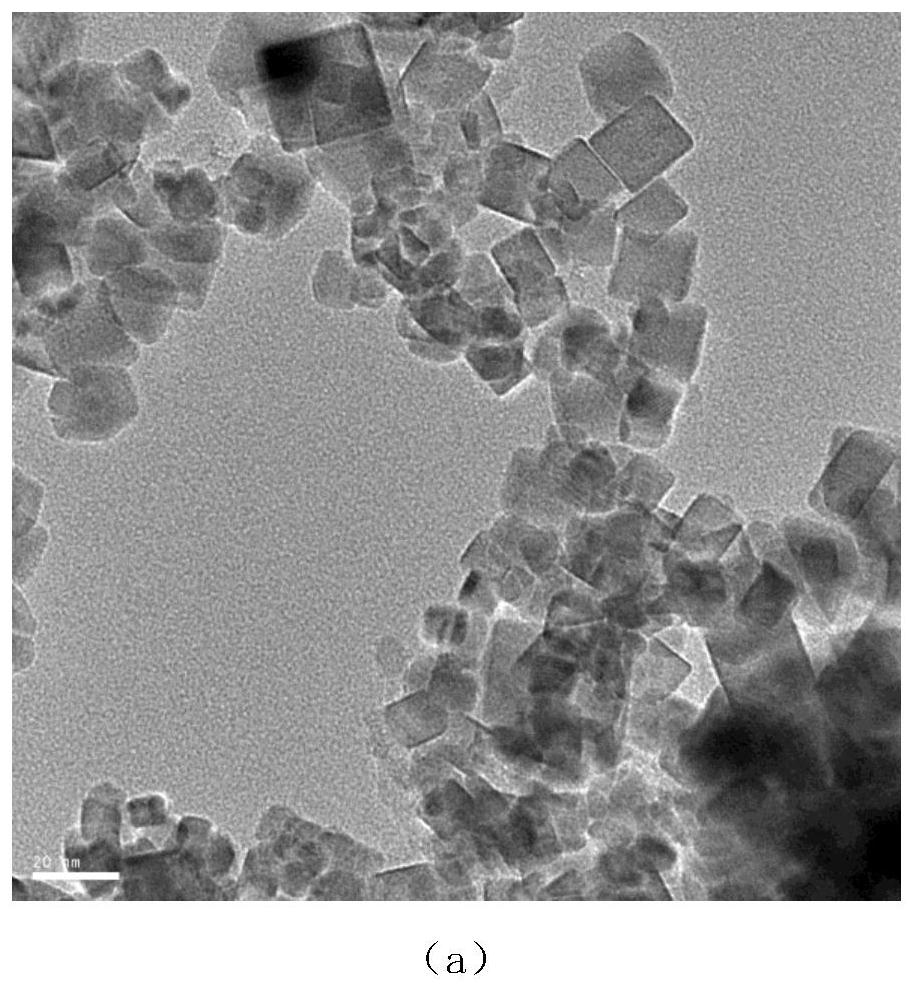

Embodiment 2

[0036] Take 2.604kg of cerium nitrate and add it to 10L of deionized water, and take 4kg of sodium hydroxide and add it to 10L of deionized water. Add 10L of pure water to the 40L volume reactor, seal and heat to 170°C, when the pressure inside the kettle is about 0.6MPa, pressurize the two storage tanks until the pressure is greater than 0.6MPa, open the switch between the storage tank and the reactor valve, inject the reaction feed liquid of cerium salt and alkali into the reaction tank. Seal the reaction tank, stir at a speed of 100 rpm, set the hydrothermal reaction temperature of the reaction tank at 180°C, carry out the hydrothermal reaction, and stop the reaction after 24 hours. After cooling to room temperature, the pressure was released, and the reaction product mixture was subjected to solid-liquid separation, washed three times with deionized water, and washed three times with ethanol. The obtained particles were dried in a vacuum oven with a temperature of 80° C. ...

Embodiment 3

[0038] Take 1.232 kg of cerium chloride and add it to 10 L of deionized water, and get 4.48 kg of potassium hydroxide and add it to 10 L of deionized water. After completely dissolving, add the two into two storage tanks for later use. Add 10L of pure water to a 40L reactor, seal and heat to 150°C, when the pressure inside the kettle is about 0.4MPa, pressurize the two storage tanks until the pressure is greater than 0.4MPa, and open the switch between the storage tank and the reactor valve, inject the reaction feed liquid of cerium salt and alkali into the reaction tank. Seal the reaction tank, stir at a speed of 100 rpm, set the hydrothermal reaction temperature of the reaction tank at 160° C., carry out the hydrothermal reaction, and stop the reaction after 36 hours. After cooling to room temperature, the pressure was released, and the reaction product mixture was subjected to solid-liquid separation, washed three times with deionized water, and washed three times with etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com