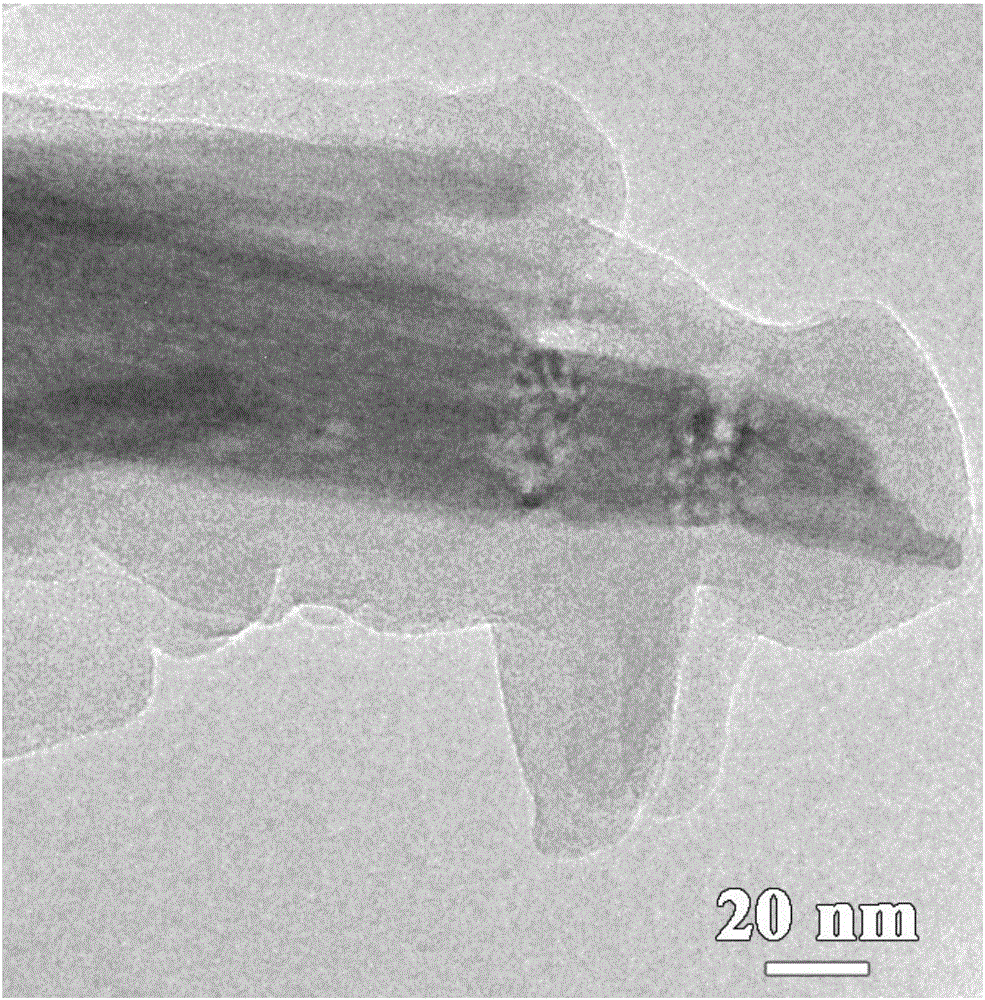

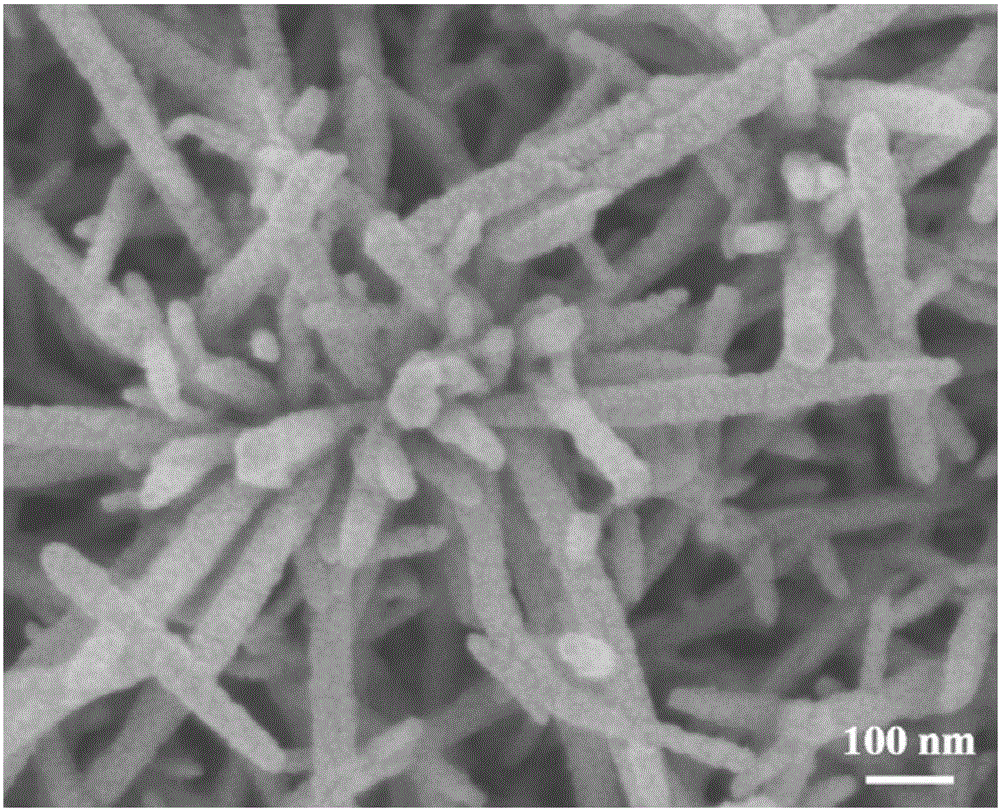

Tungsten trioxide/polyaniline core-shell nanowire array color-changing film and preparation method thereof

A technology of core-shell nano and tungsten trioxide, which is applied in chemical instruments and methods, nanotechnology, nano optics, etc., can solve the problems of low ion diffusion specific surface area, unsatisfactory electrochromic performance, and small spectral adjustment range, etc., to achieve Increased specific surface area, rich variety of discoloration, and wide range of spectral adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

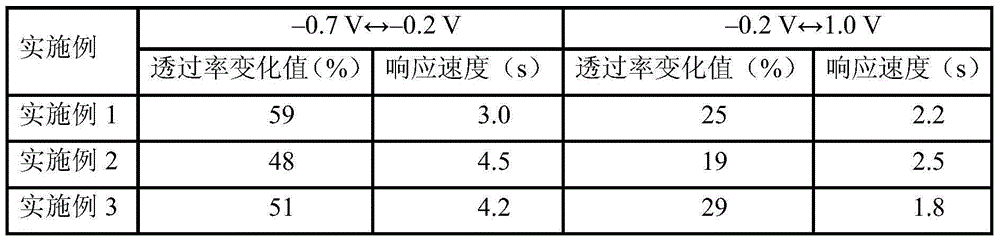

Embodiment 1

[0041] 1) Clean the FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr>85%) with acetone, deionized water and ethanol for 10 minutes, and blow it with nitrogen to get a clean FTO conductive glass ;

[0042] 2) Drop excess concentrated hydrochloric acid (10mol / L) into 1mol / L sodium tungstate aqueous solution until no new precipitates are formed, wash the precipitates with deionized water, and the milky white to pale yellow colloidal precipitates obtained after washing are White tungstic acid, the obtained white tungstic acid is dissolved in an aqueous hydrogen peroxide solution with a mass percentage of hydrogen peroxide of 30%, the molar ratio of white tungstic acid to hydrogen peroxide in an aqueous hydrogen peroxide solution is 1:3, and deionized Water is prepared into peroxide tungstic acid solution containing tungsten at a concentration of 3mol / L, and refrigerated at 4°C for later use;

[0043] 3) Spin-coat the peroxide tungstic acid solut...

Embodiment 2

[0056] 1) Clean the FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr>85%) with acetone, deionized water and ethanol for 10 minutes, and blow it with nitrogen to get a clean FTO conductive glass ;

[0057] 2) Drop excess concentrated hydrochloric acid (10mol / L) into 1mol / L sodium tungstate aqueous solution until no new precipitates are formed, wash the precipitates with deionized water, and the milky white to pale yellow colloidal precipitates obtained after washing are White tungstic acid, the obtained white tungstic acid is dissolved in an aqueous hydrogen peroxide solution with a mass percentage of hydrogen peroxide of 30%, the molar ratio of white tungstic acid to hydrogen peroxide in an aqueous hydrogen peroxide solution is 1:3, and deionized Water is prepared into peroxide tungstic acid solution containing tungsten at a concentration of 3mol / L, and refrigerated at 4°C for later use;

[0058] 3) Spin-coat the peroxide tungstic acid solut...

Embodiment 3

[0068] 1) Clean the FTO conductive glass (Shenzhen Disprey Photoelectric Material Co., Ltd., Rs≤10ohmTr>85%) with acetone, deionized water and ethanol for 10 minutes, and blow it with nitrogen to get a clean FTO conductive glass ;

[0069] 2) Drop excess concentrated hydrochloric acid (10mol / L) into 1mol / L sodium tungstate aqueous solution until no new precipitates are formed, wash the precipitates with deionized water, and the milky white to pale yellow colloidal precipitates obtained after washing are White tungstic acid, the obtained white tungstic acid is dissolved in an aqueous hydrogen peroxide solution with a mass percentage of hydrogen peroxide of 30%, the molar ratio of white tungstic acid to hydrogen peroxide in an aqueous hydrogen peroxide solution is 1:3, and deionized Water is prepared into peroxide tungstic acid solution containing tungsten at a concentration of 3mol / L, and refrigerated at 4°C for later use;

[0070] 3) Spin-coat the peroxide tungstic acid solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com