A wastewater treatment device based on three-dimensional zinc oxide and its application method

A wastewater treatment and zinc oxide technology, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, light water/sewage treatment, etc., can solve the problem of not using sewage treatment equipment, difficulty in separating nanoparticles, and nanophotocatalysis Material technology has not been widely used and other problems, to achieve excellent photochemical properties, broaden the scope of application, and increase the effect of photocatalytic reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method containing three-dimensional zinc oxide filter screen, comprising the following steps:

[0045] S1, cleaning: choose nickel or copper or silver material as the substrate, and put the substrate material into acetone, ethanol, and deionized water in sequence for ultrasonic cleaning;

[0046] S2, placing the base material cleaned in step S1 in an oven to dry, and cooling for use;

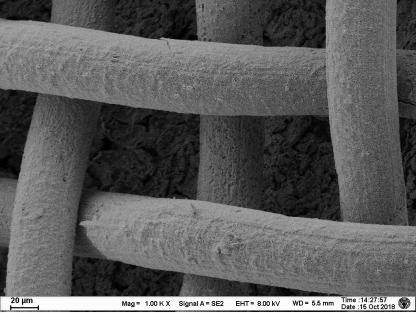

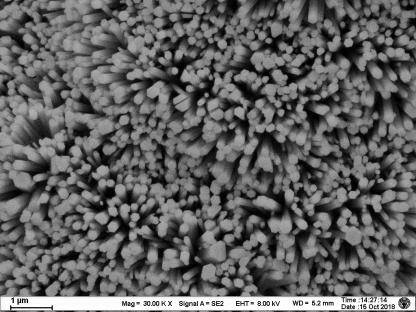

[0047] S3, by the magnetron sputtering method, the zinc oxide target is hit on the cooled base material, in an atmosphere with a nitrogen-oxygen ratio of 5:50, and the atmosphere pressure is between 2 Pa, so that the base material grows and oxidizes Zinc seed layer; the seed layer is grown by magnetron sputtering, and the obtained zinc oxide nanorods have the advantages of uniform length, uniform thickness, regular and dense growth;

[0048]S4, growing zinc oxide nanorods on the basis of the seed layer formed in step S3 by a hydrothermal method to obtain a three-dimensional...

Embodiment 2

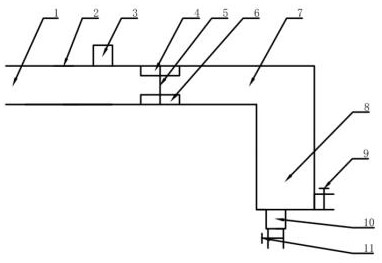

[0051] A wastewater treatment device based on three-dimensional zinc oxide, such as figure 2 As shown, it includes a wastewater treatment pipe 2, a water inlet 1, the water inlet 1 is located at one end of the wastewater treatment pipe 2, and the flow rate control device 3 is located outside the water inlet 1 for controlling the flow rate of the wastewater, and also includes Zinc oxide-containing filter screen 5 and ultraviolet lamps (4, 6), the zinc oxide-containing filter screen 5 is fixed in the middle of the waste water treatment pipeline 2 The ultraviolet lamp (4, 6) is located in the zinc oxide-containing filter screen 5 one side, and is fixedly connected to the top of the waste water treatment pipeline 2, the number of the ultraviolet lamps is an even number, and this embodiment is two ultraviolet lamps, which are respectively the ultraviolet lamp 4 and the ultraviolet lamp 6, and the ultraviolet lamps 4 and 6 Ultraviolet lamp 6 uses ultraviolet light with a wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com