Efficient durable gas phase antirust agent and preparation method thereof

A gas-phase anti-rust agent and durable technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of single anti-rust object, short anti-rust time, low anti-rust efficiency, etc., and achieve the effect of facilitating industrial production and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

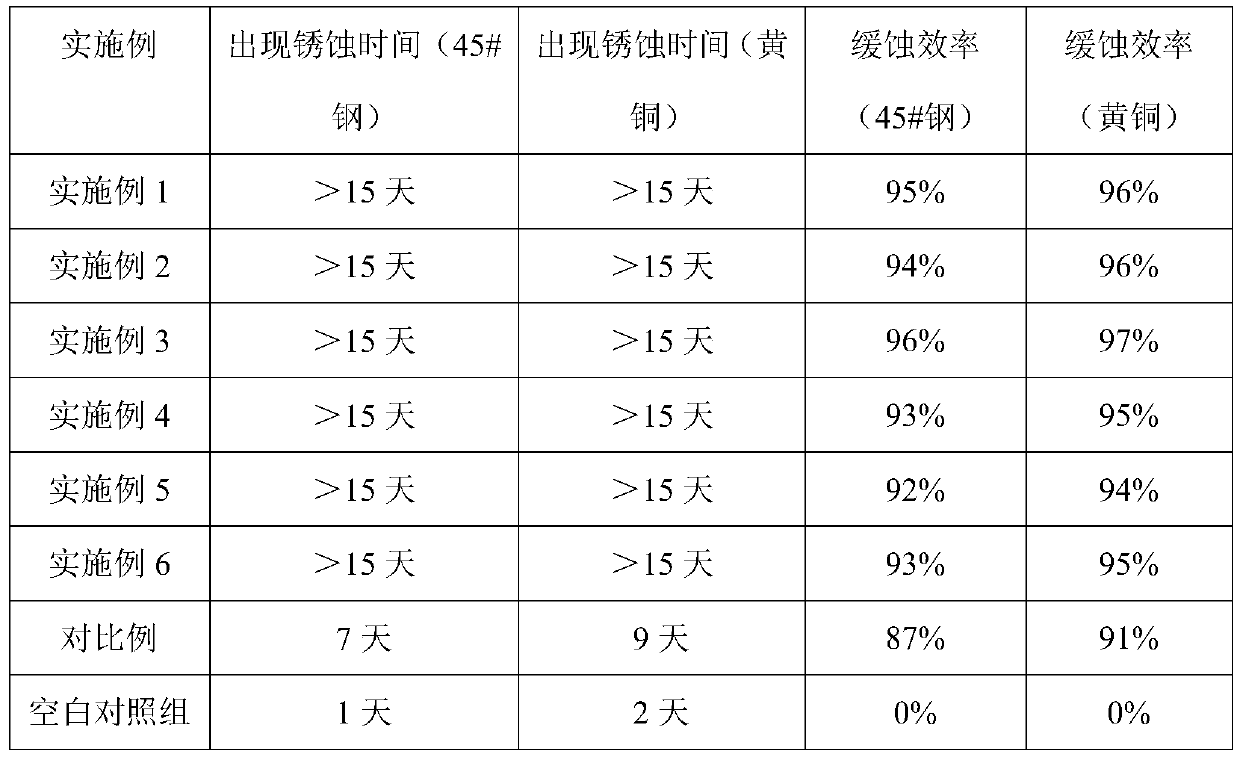

Examples

Embodiment 1

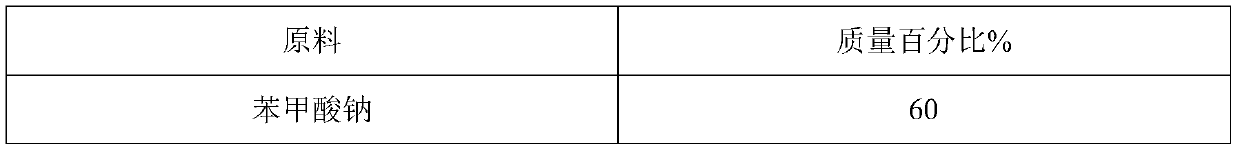

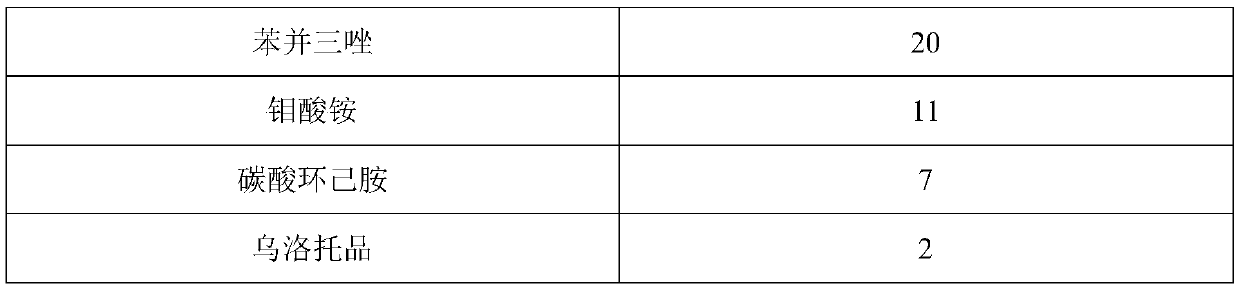

[0024] This embodiment provides a high-efficiency and durable gas-phase antirust agent. The components and parts of the antirust agent are shown in the following table in terms of parts by weight of each component:

[0025] raw material Mass % sodium benzoate 60 Benzotriazole 20 Ammonium molybdate 10 Cyclohexylamine carbonate 3 Herotropine 7

[0026] Preparation:

[0027] (1) benzotriazole, ammonium molybdate, cyclohexylamine carbonate, urotropine are mixed, stir evenly;

[0028] (2) Mix the mixture obtained in step (1) with sodium benzoate, stir to obtain a powdery material, which is the A component;

[0029] The preparation of the B component includes the following steps: washing and drying the celery stalks, beating, adding absolute ethanol according to the solid-liquid ratio of 1ml:3ml, soaking for 10-12h, using ultrasonic-assisted extraction, and filtering to obtain The B component.

[0030] When using, component A and compo...

Embodiment 2

[0032] This embodiment provides a high-efficiency and durable vapor phase antirust agent. The components and parts of the antirust agent are shown in the following table in terms of parts by weight of each component

[0033] raw material Mass % sodium benzoate 70 Benzotriazole 15 Ammonium molybdate 5 Cyclohexylamine carbonate 2 Herotropine 8

[0034] Preparation:

[0035] (1) benzotriazole, ammonium molybdate, cyclohexylamine carbonate, urotropine are mixed, stir evenly;

[0036] (2) Mix the mixture obtained in step (1) with sodium benzoate, stir to obtain a powdery material, which is the A component;

[0037] The preparation of the B component includes the following steps: washing and drying the celery stalks, beating, adding absolute ethanol according to the solid-liquid ratio of 1ml:7ml, soaking for 10-12h, using ultrasonic-assisted extraction, and filtering to obtain The B component.

[0038] When using, component A and compo...

Embodiment 3

[0040] This embodiment provides a high-efficiency and durable vapor phase antirust agent. The components and parts of the antirust agent are shown in the following table in terms of parts by weight of each component

[0041] raw material Mass % sodium benzoate 50 Benzotriazole 25 Ammonium molybdate 15 Cyclohexylamine carbonate 7 Herotropine 3

[0042] Preparation:

[0043] (1) benzotriazole, ammonium molybdate, cyclohexylamine carbonate, urotropine are mixed, stir evenly;

[0044] (2) Mix the mixture obtained in step (1) with sodium benzoate, stir to obtain a powdery material, which is the A component;

[0045] The preparation of the B component comprises the following steps: washing and drying the celery stalks, beating, adding absolute ethanol according to the solid-liquid ratio of 1ml:10ml, soaking for 10-12h, using ultrasonic-assisted extraction, and filtering to obtain The B component.

[0046] When using, component A and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com