NiCrAlY/NiCrAlY-YSZ/YSZ thermal barrier coating on surface of nickel-based alloy and preparation method thereof

A nickel-based alloy, thermal barrier coating technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of immature preparation technology, complex preparation process, and failure to be widely used. , to achieve the effect of avoiding cracking and peeling failure, simple process and alleviating thermal mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

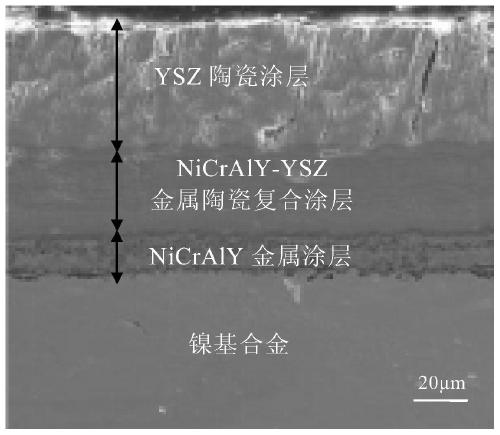

[0028] The preparation method of the NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of the DZ125 nickel-based alloy of the present embodiment comprises the following steps:

[0029] Step 1. Use 80#, 200#, 400#, 600#, 800#, 1000# water sandpaper to polish the DZ125 nickel-based alloy step by step, and then put it into acetone for ultrasonic cleaning for 15 minutes;

[0030] Step 2, using electron beam physical vapor deposition to deposit a NiCrAlY metal coating with a thickness of 20 μm on the surface of the DZ125 nickel-based alloy after ultrasonic cleaning in step 1; the process parameters of the electron beam physical vapor deposition are: deposition The chamber vacuum is less than 3×10 -3 Pa, the temperature of the DZ125 nickel-based alloy after ultrasonic cleaning is 800°C, the evaporation current of the NiCrAlY target is 1.0A, the rotation speed is 5r / min, and the distance between the target and the base is 300mm;

[0031] Step 3, using electron beam phys...

Embodiment 2

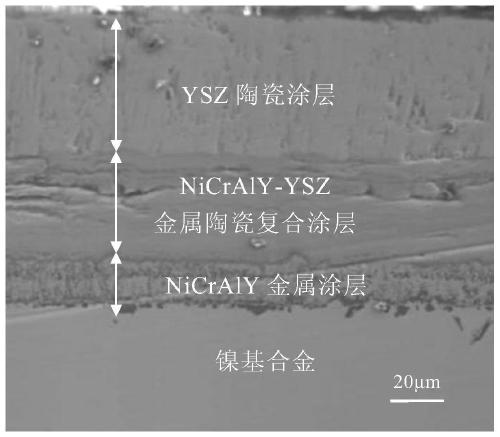

[0037] The preparation method of the NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of the DZ125 nickel-based alloy of the present embodiment comprises the following steps:

[0038] Step 1. Use 80#, 200#, 400#, 600#, 800#, 1000# water abrasive paper to polish the DZ125 nickel-based alloy step by step, and then put it into acetone for ultrasonic cleaning for 10 minutes;

[0039] Step 2, using electron beam physical vapor deposition to deposit a NiCrAlY metal coating with a thickness of 10 μm on the surface of the DZ125 nickel-based alloy after ultrasonic cleaning in step 1; the process parameters of the electron beam physical vapor deposition are: deposition The chamber vacuum is less than 3×10 -3 Pa, the temperature of the DZ125 nickel-based alloy after ultrasonic cleaning is 900°C, the evaporation current of the NiCrAlY target is 0.8A, the rotation speed is 15r / min, and the distance between the target and the base is 500mm;

[0040] Step 3. Depositing a NiCrA...

Embodiment 3

[0044] The preparation method of the NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of the DZ125 nickel-based alloy of the present embodiment comprises the following steps:

[0045] Step 1. Use 80#, 200#, 400#, 600#, 800#, 1000# water abrasive paper to polish the DZ125 nickel-based alloy step by step, and then put it into acetone for ultrasonic cleaning for 30 minutes;

[0046] Step 2, using electron beam physical vapor deposition to deposit a NiCrAlY metal coating with a thickness of 30 μm on the surface of the DZ125 nickel-based alloy after ultrasonic cleaning in step 1; the process parameters of the electron beam physical vapor deposition are: deposition The chamber vacuum is less than 3×10 -3 Pa, the temperature of the DZ125 nickel-based alloy after ultrasonic cleaning is 700°C, the evaporation current of the NiCrAlY target is 1.2A, the rotation speed is 10r / min, and the distance between the target and the base is 200mm;

[0047] Step 3. Depositing a NiCrA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com