Surface graphene graphite-based carbon material and preparation method and application thereof

A graphite-based, carbon material technology, applied in the analysis of materials, material electrochemical variables, material analysis by electromagnetic means, etc. The effect of detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

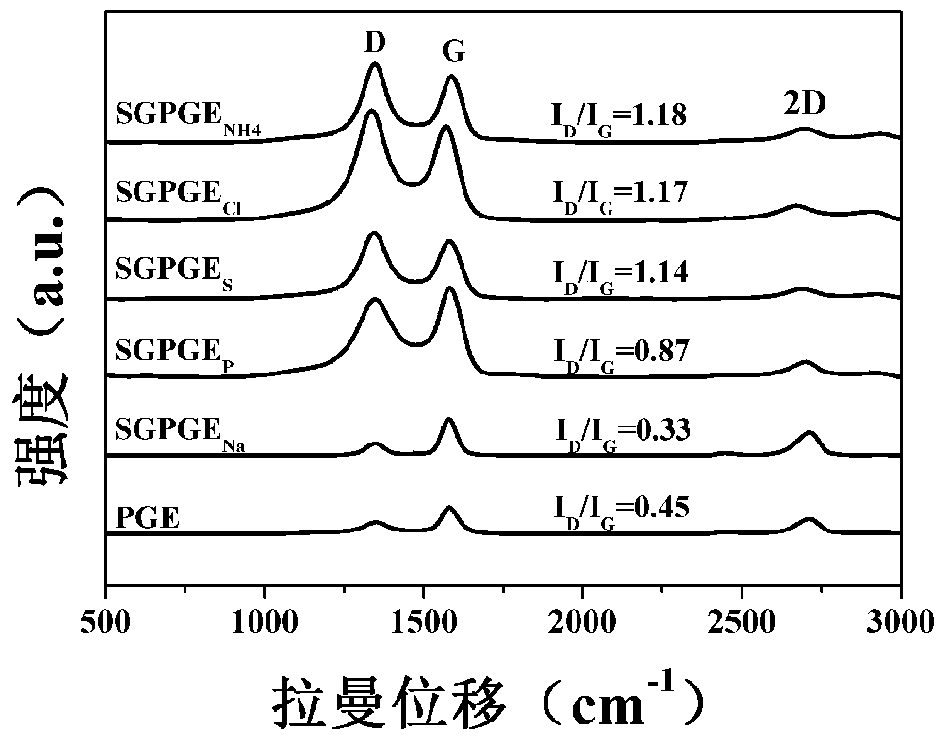

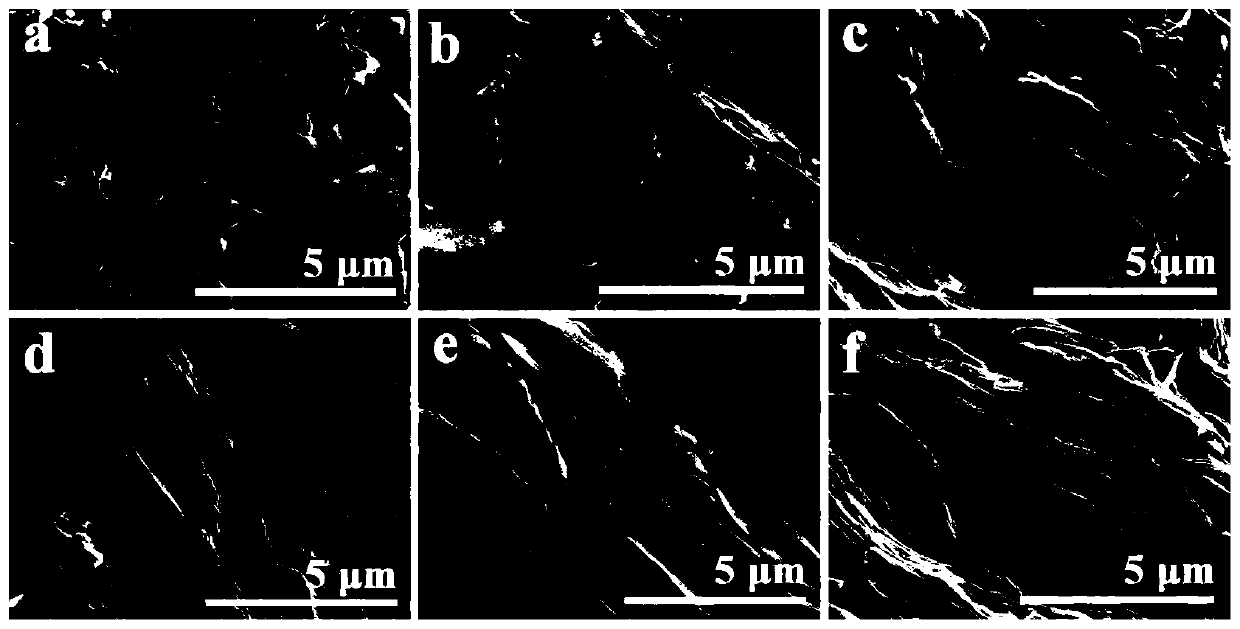

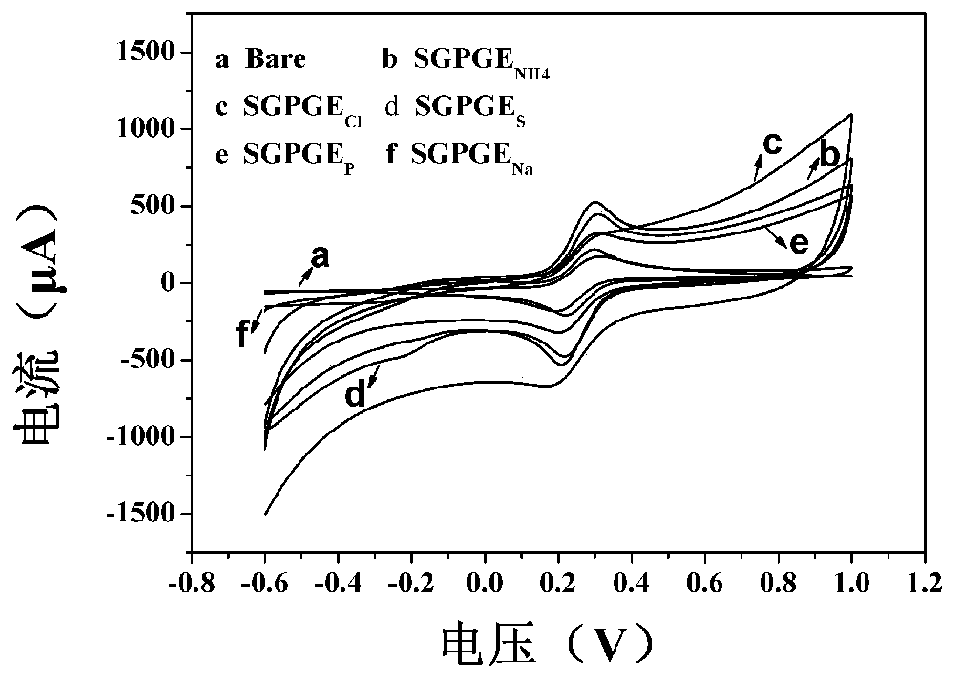

[0037] The preparation method of surface graphene graphite rod, the main steps are as follows:

[0038] (1) Using a two-electrode system, graphite rods and Pt sheets are used as anode and cathode respectively, and the area immersed in the solution is controlled with a raw material tape (the length of each graphite rod immersed in the solution is 5 mm), and the graphite rod and the Pt sheet are connected by conductive copper wire. connected to the electrochemical workstation;

[0039] (2) at 1.0mol L -1 In the NaOH solution of NaOH, the surface layer of the graphite rod is electrochemically delaminated by i-t curve technology to generate graphene. Under the polarization voltage of 2V and the polarization duration of 40s, the graphite rod of the anode is converted into surface graphene at room temperature Graphite rods.

[0040] The finally obtained surface graphenized graphite rod is mainly composed of graphite rod and graphene attached to the surface of the graphite rod, and...

Embodiment 2

[0042] The preparation method of surface graphenized graphite sheet, the main steps are as follows:

[0043] (1) Use a two-electrode system, use the graphite sheet and the Pt sheet as the anode and the cathode respectively, use a raw material tape to control the area immersed in the solution, and use a conductive copper wire to connect the graphite sheet to the electrochemical workstation;

[0044] (2) at 2.0mol L -1 H 2 SO 4 The i-t curve technique is used in the solution to perform electrochemical in-situ layering on the surface of graphite flakes to generate graphene. Under the polarization voltage of 3V and the polarization duration of 300s, the graphite flakes of the anode are converted into surface graphenized graphite at room temperature piece.

[0045] The finally prepared surface graphenized graphite sheet is mainly composed of graphite sheet and graphene attached to the surface of the graphite sheet, and the graphite sheet and graphene are combined by intermolecul...

Embodiment 3

[0047] The preparation method of surface graphene graphite paper, main steps are as follows:

[0048] (1) Use a two-electrode system, use graphite paper and Pt sheet as anode and cathode respectively, use a raw material tape to control the area immersed in the solution, and use conductive copper wire to connect the graphite paper to the electrochemical workstation;

[0049] (2) At 5.0mol·L -1 The surface layer of graphite paper is electrochemically delaminated in situ by i-t curve technology in HCl solution to generate graphene. Under the polarization voltage of 3.5V and the polarization duration of 100s, the graphite paper of the anode is converted into surface graphite at room temperature Graphite paper.

[0050] The finally prepared surface graphenized graphite paper is mainly composed of graphite paper and graphene attached to the surface of the graphite paper, and the graphite paper and graphene are combined by intermolecular force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com