Good flexible sandwich type PN junction electrical memory device

A sandwich type, PN junction technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of poor flexibility, poor high temperature resistance, etc., and achieve the effects of simple preparation, high ternary yield, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one: preparation based on semiconductor material (compound A-PC 60 BM) semiconductor electric storage device

[0037] Concrete preparation process is as follows:

[0038] 1. ITO glass (about 2 cm×2 cm in size) was washed with washing powder, ultrapure water, acetone, and ethanol were ultrasonicated for 10 minutes, and ITO was treated with hydrogen peroxide for surface modification, soaked in ethanol, and sealed. use;

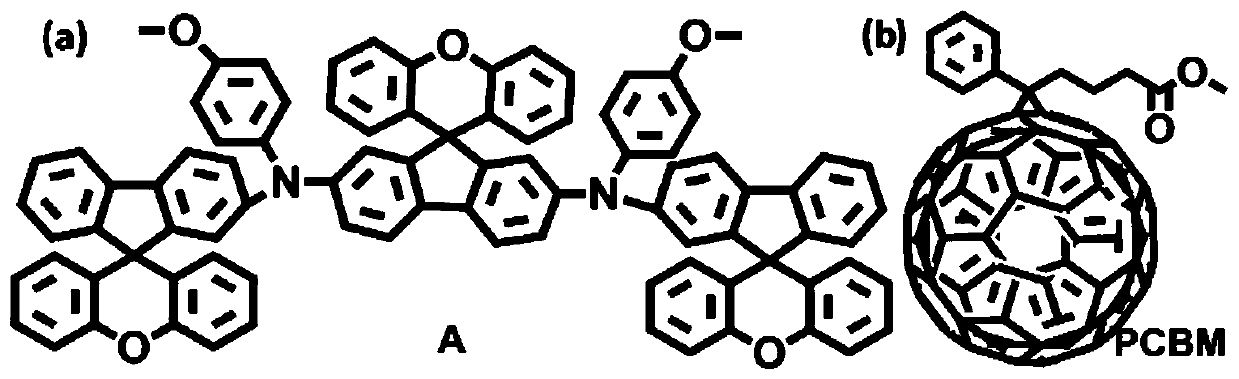

[0039] 2. Compound A, PC 60 BM was dissolved in chlorobenzene to configure the solution; figure 1 (a) and (b) are semiconductor material compound A, PC of the present invention respectively 60 Schematic diagram of the molecular structure of BM;

[0040] 3. Dry the ITO glass, and spin-coat the prepared solution on the conductive surface at different speeds;

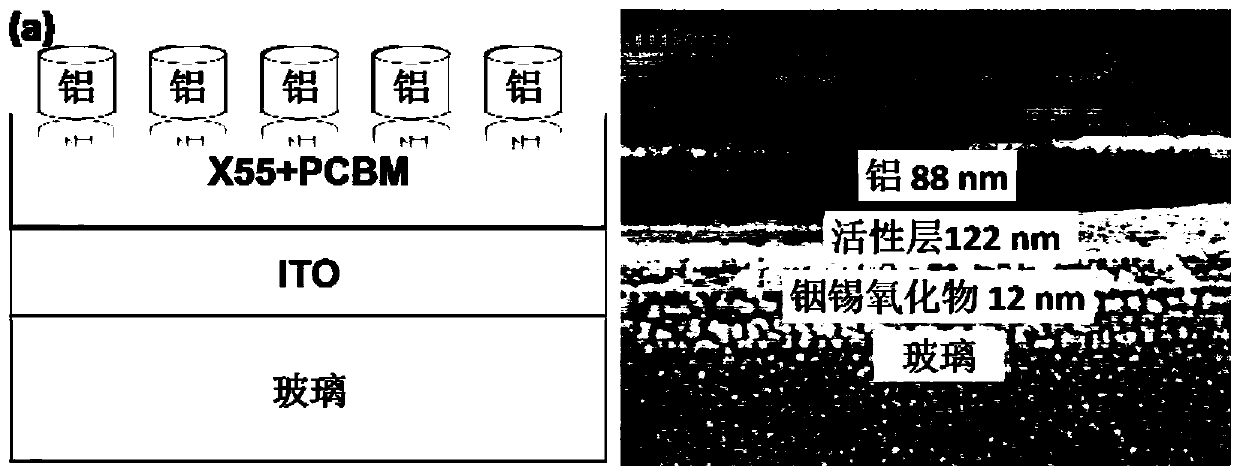

[0041] 4. Store the prepared device in a cell culture plate and anneal at 80°C for 12 hours to prepare a PN junction electrical storage material; the thickness is 122 nm;

[0042] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com