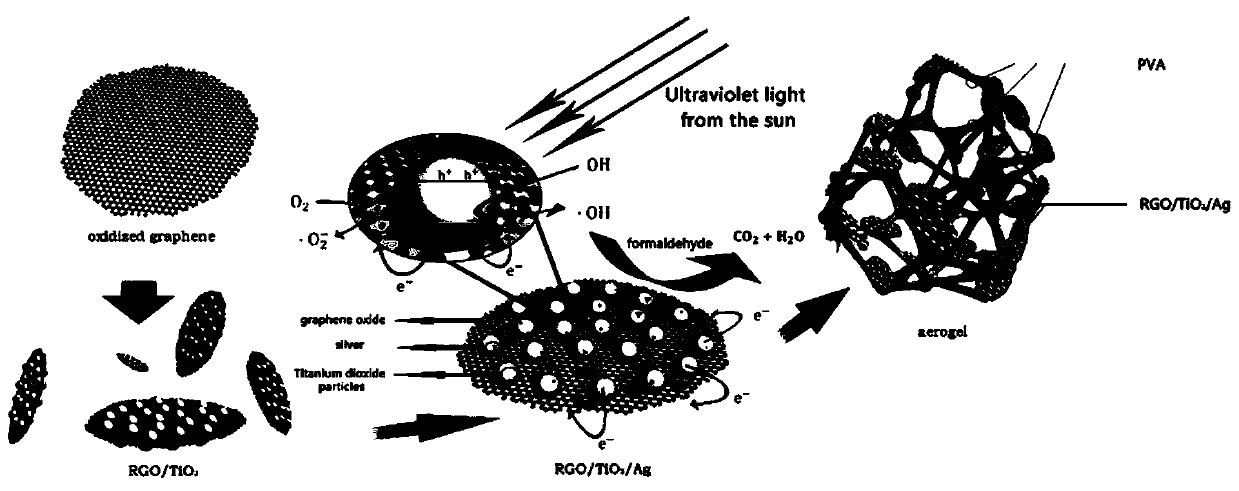

RGO/TiO2/Ag aerogel-type photocatalyst and preparation method and application thereof

A photocatalyst, aerogel technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

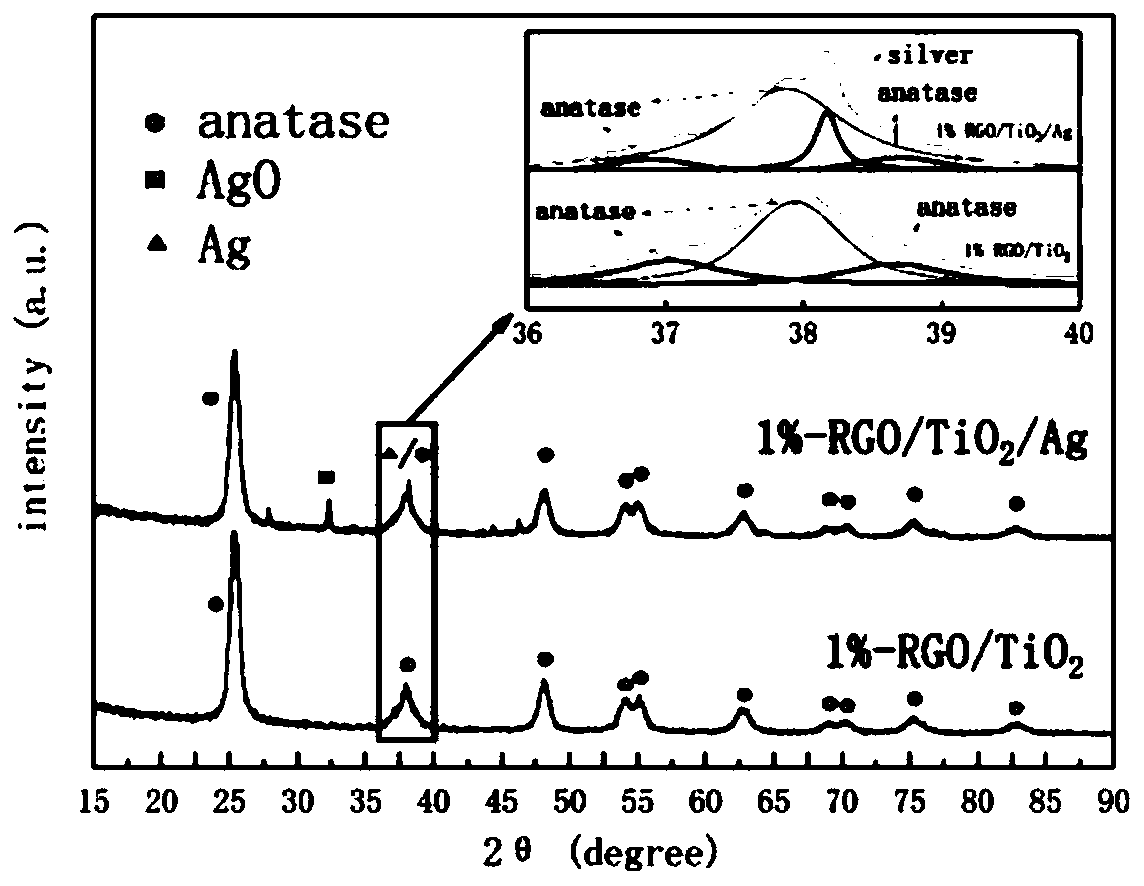

[0047] Example 1: 1%-RGO / TiO 2 The preparation method of / Ag airgel type photocatalyst, step is as follows:

[0048] 1) 1%-RGO / TiO 2 Preparation: Mix graphene oxide and butyl titanate in absolute ethanol at a mass ratio of 0.02:9, stir in a constant temperature water bath at 35°C until uniformly mixed to obtain a mixed solution; mix hydrochloric acid, absolute ethanol and deionized water by volume The ratio of 1.8:50:12 was mixed to make a titration solution; using the sol-gel method, the titration solution was added to the mixture until a gel was formed; the gel was first aged for 6 hours, then dried at 60°C and ground into powder, and then in Heat treatment in a tube furnace at 400 °C for 3 h under nitrogen atmosphere to obtain RGO / TiO 2 catalyst of light;

[0049] 2) 1%-RGO / TiO 2 Preparation of / Ag photocatalyst powder: under absolute ethanol system, the RGO / TiO obtained in step 1) 2 Photocatalyst and silver nitrate are mixed at a mass ratio of 1:0.03, RGO / TiO 2 The mas...

Embodiment 2

[0051] Example 2: 5%-RGO / TiO 2 The preparation method of / Ag airgel type photocatalyst, step is as follows:

[0052] 1) 5%-RGO / TiO 2 Preparation: Mix graphene oxide and butyl titanate in absolute ethanol at a mass ratio of 0.1:9, stir in a constant temperature water bath at 35°C until uniformly mixed to obtain a mixed solution; mix hydrochloric acid, absolute ethanol and deionized water by volume The ratio of 1.8:50:12 was mixed to make a titration solution; using the sol-gel method, the titration solution was added to the mixture until a gel was formed; the gel was first aged for 6 hours, then dried at 60°C and ground into powder, and then in Heat treatment in a tube furnace at 400 °C for 3 h under nitrogen atmosphere to obtain RGO / TiO 2 catalyst of light;

[0053] 2) 5%-RGO / TiO 2 Preparation of / Ag photocatalyst powder: under absolute ethanol system, the RGO / TiO obtained in step 1) 2 Photocatalyst and silver nitrate are mixed at a mass ratio of 1:0.03, RGO / TiO 2 The mass...

Embodiment 3

[0055] Example 3: 10%-RGO / TiO 2 The preparation method of / Ag airgel type photocatalyst, step is as follows:

[0056] 1) 10%-RGO / TiO 2 Preparation: Mix graphene oxide and butyl titanate in absolute ethanol at a mass ratio of 0.2:9, stir in a constant temperature water bath at 35°C until evenly mixed to obtain a mixed solution; mix hydrochloric acid, absolute ethanol and deionized water by volume The ratio of 1.8:50:12 was mixed to make a titration solution; using the sol-gel method, the titration solution was added to the mixture until a gel was formed; the gel was first aged for 6 hours, then dried at 60°C and ground into powder, and then in Heat treatment in a tube furnace at 400 °C for 3 h under nitrogen atmosphere to obtain RGO / TiO 2 catalyst of light;

[0057] 2) 10%-RGO / TiO 2 / Ag photocatalyst powder preparation: under absolute ethanol system, the RGO / TiO obtained in step 1) 2 Photocatalyst and silver nitrate are mixed at a mass ratio of 1:0.03, RGO / TiO 2 The mass v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com