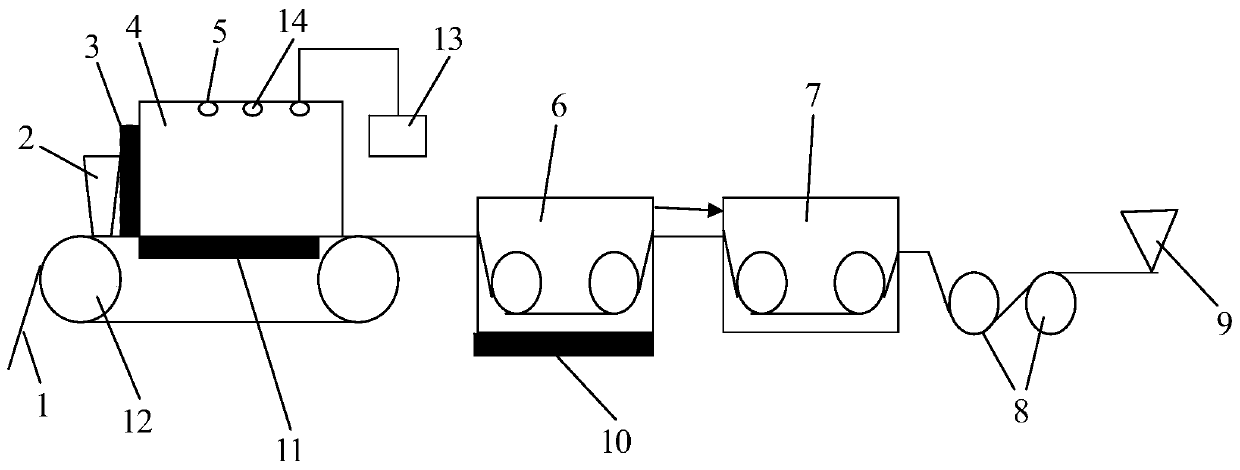

Ion exchange membrane casting continuous forming method and device

An ion exchange membrane and molding method technology, which is applied to flat products, household appliances, other household appliances, etc., can solve the problems of high rejection rate, poor film thickness uniformity, low ion exchange membrane production efficiency, etc., and improve the product yield. , The requirements are not high, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, 8 kg of perfluorosulfonic acid resin and 0.5 kg of polyvinylidene fluoride (PVDF) resin were dissolved in 30 L of dimethylacetamide (DMAC), heated and stirred at 220 ° C for 6 hours to form a film-forming slurry. Vacuum degassing was carried out under stirring. Put the film-making slurry into the feeding system, enter the casting machine through the connected pipeline, and control the thickness of the solution through the scraper, and enter the film-making slurry into the three The temperature section is solidified and formed, and finally wound up and cut to obtain a perfluorosulfonic acid ion exchange membrane. The thickness of the ion exchange membrane is 150 microns.

Embodiment 2

[0029] In this example, 10 kg of polybenzimidazole resin was dissolved in 40 L of dimethylformamide (DMF), stirred and dissolved at room temperature for 7 hours to form a film-forming slurry, and stirred and vacuumed for defoaming. Put the film-making slurry into the feeding system, enter the casting machine through the connected pipeline, and control the thickness of the solution through the scraper, and enter the film-making slurry into the three The temperature section is solidified and formed. After forming, the film is put into a phosphoric acid aqueous solution with a concentration of 70wt% for treatment at 70°C. Finally, it is wound and cut to obtain an ion-exchange membrane. The thickness of the ion-exchange membrane is 100 microns.

Embodiment 3

[0031]In this example, 10 kg of polyvinylidene fluoride resin was dissolved in 40 L of dimethylacetamide (DMAC), stirred and dissolved at 80°C for 8 hours to form a film-forming slurry, and 500 mL of the additive polyvinyl alcohol resin (PVA) was added to the In the above solution, stir for 2 hours and oscillate in an ultrasonic wave to refine the solution and drive away the tiny bubbles therein, and carry out stirring and vacuum degassing. Put the film-making slurry into the feeding system, enter the casting machine through the connected pipeline, and control the thickness of the solution through the scraper, and enter the film-making slurry into the three The temperature section is solidified and formed. After heat treatment, the membrane enters the mixed solution of extractant ethanol and deionized water for extraction, and then enters the cleaning tank for cleaning with deionized water to prepare a porous membrane. Finally, it is hot-pressed and cut to obtain a porous membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com