A kind of method for continuously preparing trifluoroacetic acid by hydrolysis of trifluoroacetyl chloride

A technology of trifluoroacetyl chloride and trifluoroacetic acid, applied in the directions of acid halide preparation, organic chemistry, etc., can solve problems such as low hydrolysis and absorption efficiency of trifluoroacetyl chloride, and achieve the advantages of improving mixing efficiency, short reaction time and improving conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

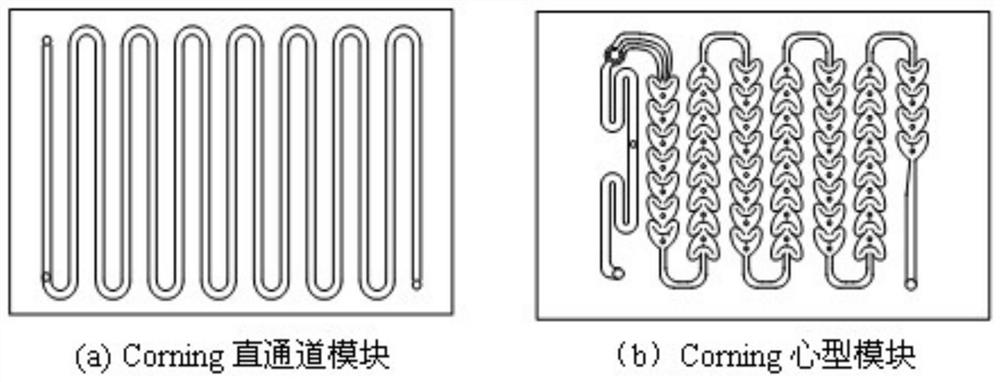

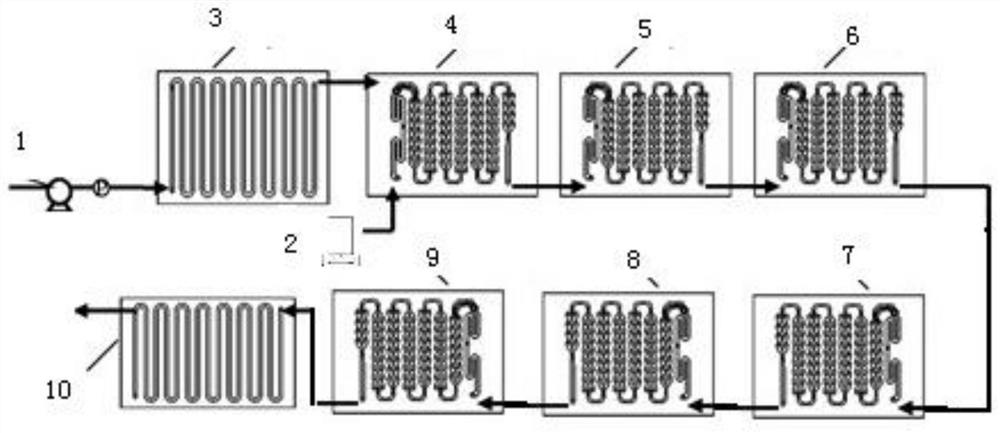

[0037] optional figure 2 1 piece of corning straight channel module (as premix preheating module 3), 6 pieces of corning "heart-shaped" microchannel reaction module, 1 piece of corning straight channel module (as quenching module 10). According to the attached image 3 The reaction scheme shown constitutes a continuous flow microchannel reaction system. The reaction heat exchange medium adopts heat conduction oil. According to the principle of forced heat transfer in the microchannel reactor, only two temperature measurement points are set at the inlet and outlet of the reactor. Before the reaction, the microchannel reaction system and the connecting pipeline were dewatered and dried respectively, and the air tightness of 1.0 MPa was checked. by attaching image 3 A liquid phase pump (such as a diaphragm metering pump) in the microchannel reaction system continuously and stably adds raw water to the microchannel reaction system. by attaching image 3 2 gas mass flow meters...

Embodiment 2

[0041] The same Corning microchannel reactor was used as in Example 1, and the same connection method and control method were used. This example changes the reaction conditions.

[0042] The heat exchanger temperature was set at 70°C, that is, the reaction temperature, and the reaction pressure was set at 0.1 MPa. The feed rate of raw material water is 2.25g / min, the feed rate of trifluoroacetyl chloride gas is 3.31g / min, the residence time of the reaction is 8s, and the molar ratio of water and trifluoroacetyl chloride is 5:1. The reaction raw materials enter the "heart-shaped" micro-channel reaction module 4 through the micro-channel premixing preheating module 3, and the trifluoroacetyl chloride gas directly enters the "heart-shaped" micro-channel reaction module 4 through the gas mass flowmeter. In microchannel reaction modules 4-9, trifluoroacetyl chloride reacts with water. The crude reaction product was collected by quenching module 10 to obtain crude trifluoroacetic ac...

Embodiment 3

[0045] The same Corning microchannel reactor was used as in Example 1, and the same connection method and control method were used. This example changes the reaction conditions.

[0046] The heat exchanger temperature was set to 50°C, that is, the reaction temperature, and the reaction pressure was set to 0MPa. The feed rate of raw material water is 3.60g / min, the feed rate of trifluoroacetyl chloride gas is 5.30g / min, the residence time of the reaction is 10s, and the molar ratio of water and trifluoroacetyl chloride is 5:1. The reaction raw materials enter the "heart-shaped" micro-channel reaction module 4 through the micro-channel premixing preheating module 3, and the trifluoroacetyl chloride gas directly enters the "heart-shaped" micro-channel reaction module 4 through the gas mass flowmeter. In microchannel reaction modules 4-9, trifluoroacetyl chloride reacts with water. The crude reaction product was collected by quenching module 10 to obtain crude trifluoroacetic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com