Internal-heating type clean coking process and system

An internal heating and heating system technology, applied in the field of coal coking, can solve the problems of investment in coking production enterprises, failure to effectively implement emission reduction measures, etc., to widen the road of development, prevent the emission of air pollutants to the atmosphere, and achieve high efficiency The effect of utilization and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

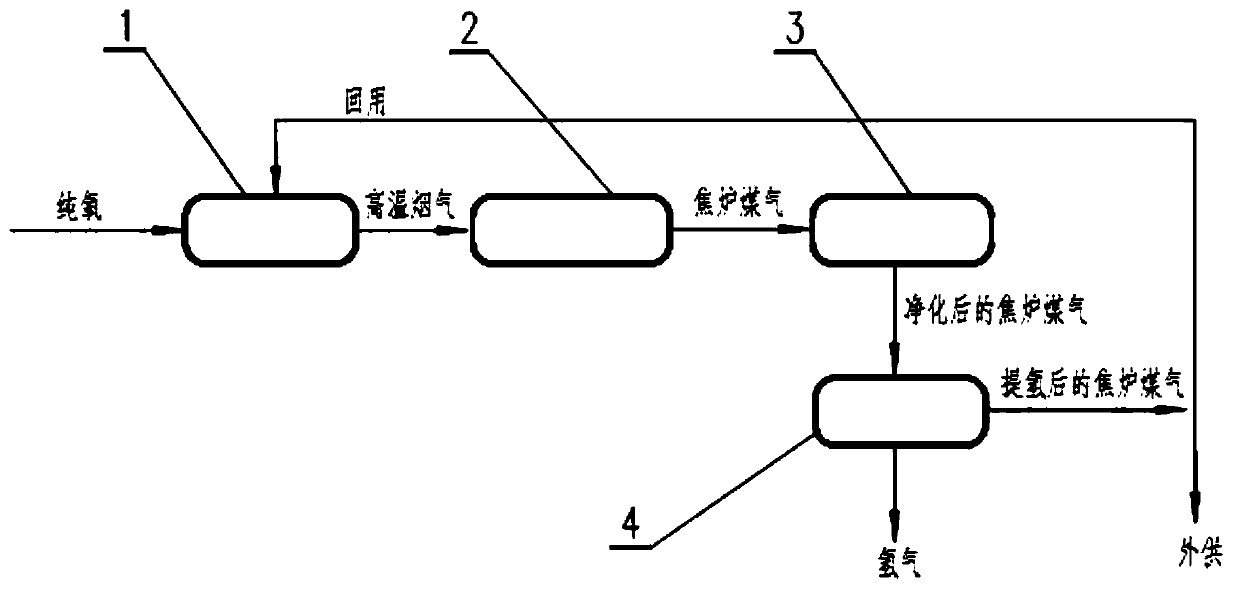

[0032] Such as figure 1 , figure 2 As shown, a kind of internal heating type clean coking process of the present invention comprises the following steps:

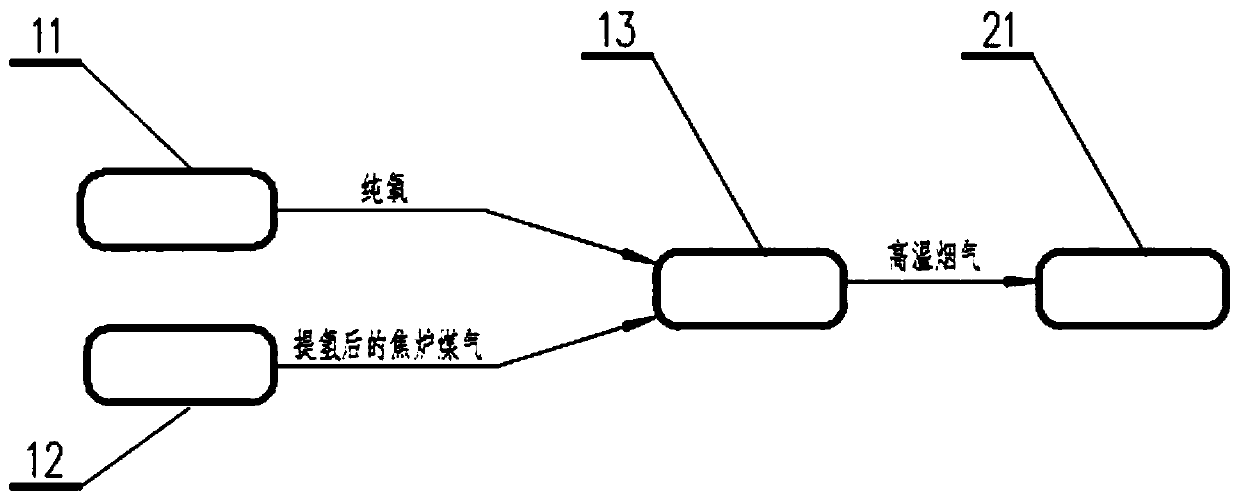

[0033] 1) In the coke oven heating system 1, pure oxygen is used as the combustion-supporting gas to participate in the heating process of the coke oven; 4 , CO and other hydrocarbon coke oven gas as fuel, in the combustion unit 13 of the coke oven heating system 1, oxygen and coke oven gas are fully combusted, and the generated high-temperature flue gas enters the subsequent high-temperature coal carbonization system 2;

[0034] 2) In the coal high-temperature carbonization system 2, the high-temperature flue gas transfers heat to the coal and generates high-temperature flue gas. The main component of the high-temperature flue gas is CO 2 、H 2 O and a small amount of SO 2 , where CO 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com