Preparation method of CuO/Cu2O/Cu ternary composite material

A technology of composite materials and mixed liquids, applied in the direction of catalyst activation/preparation, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve problems such as inability to meet photocatalytic performance requirements, and achieve short synthesis cycle, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a CuO / Cu 2 The preparation method of the O / Cu ternary composite material comprises the following steps: S1, respectively preparing copper salt solution and lye; S2, taking yeast and adding it to water for cultivation, and adding it to the copper salt solution and lye successively after cultivation to obtain a mixed solution ; S3, the mixed solution is heated and reacted to obtain the reaction solution; S4, the reaction solution is dried and then calcined and cooled to room temperature, and then calcined again to obtain CuO / Cu 2 O / Cu ternary composite material.

[0024] In order to prepare CuO / Cu with good charge separation structure, visible light absorption characteristics and reactive active sites 2 O / Cu ternary composite materials, technicians have done a lot of research, such as combining a surface plasmon resonance co-catalyst on the surface of the ternary composite material, which can effectively inhibit the recombination of photogenerated ...

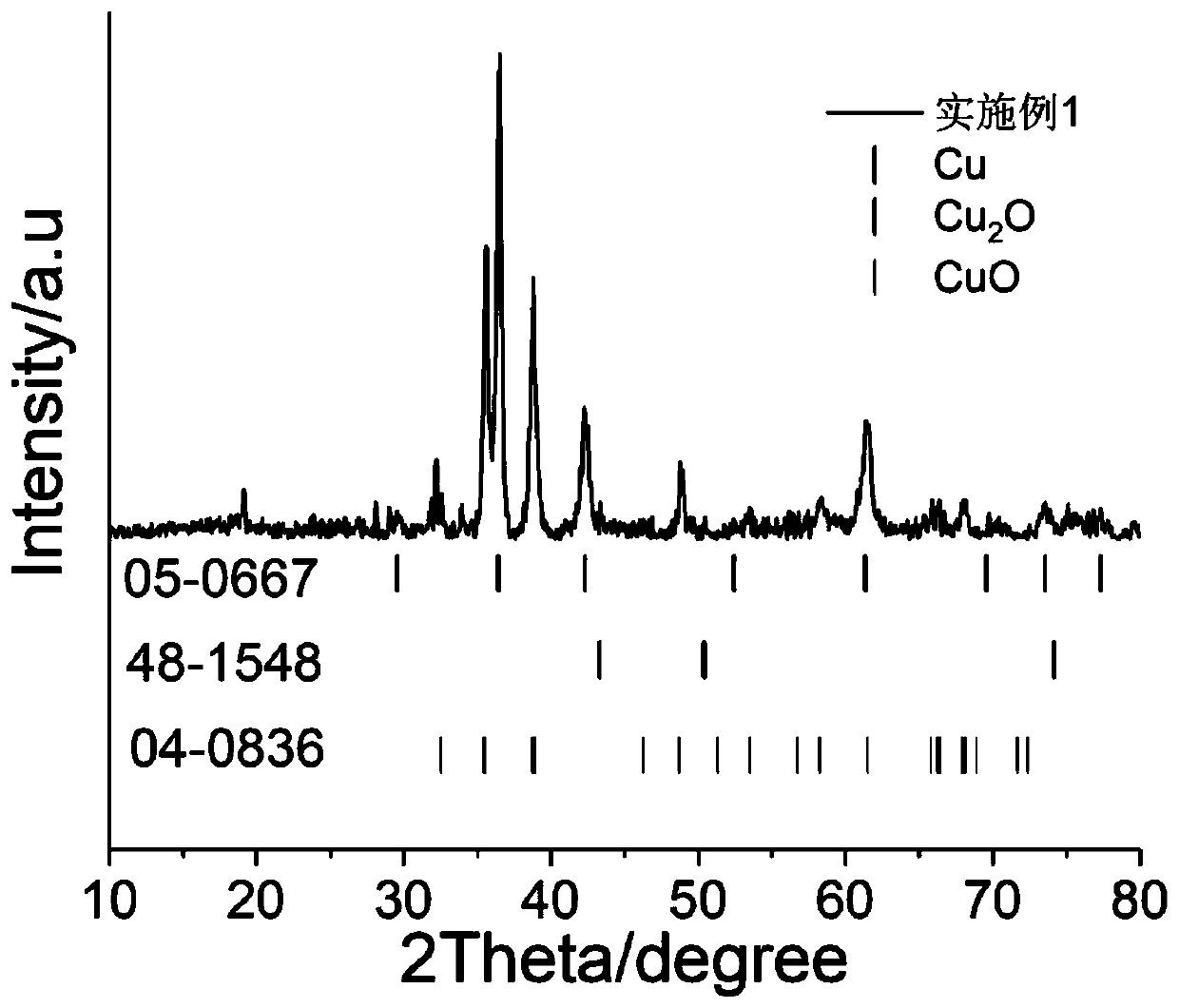

Embodiment 1

[0036] CuO / Cu in this embodiment 2 The preparation method of O / Cu ternary composite material comprises the following steps:

[0037] S1, 2.5g of analytically pure copper sulfate pentahydrate (CuSO 4 "5H 2 O) add 20mL deionized water to prepare a copper sulfate solution with a concentration of 0.5mol / L. Dissolve 0.8 g of analytically pure sodium hydroxide in 20 mL of deionized water to prepare a 1.0 mol / L sodium hydroxide solution.

[0038] S2. Add 2.0 g of yeast powder to 20 mL of deionized water and cultivate for 30 minutes. After the cultivation, add it to the copper sulfate solution, and then gradually add the above mixed solution to the sodium hydroxide alkali solution to obtain a mixed solution.

[0039] S3. Put the mixed solution obtained in step S2 in a microwave reactor, and react at a temperature of 80° C. for 5 minutes to obtain a reaction solution.

[0040] S4. The reaction solution was centrifuged at 5000 rpm and dried in a drying oven at 80° C. for 12 hours. ...

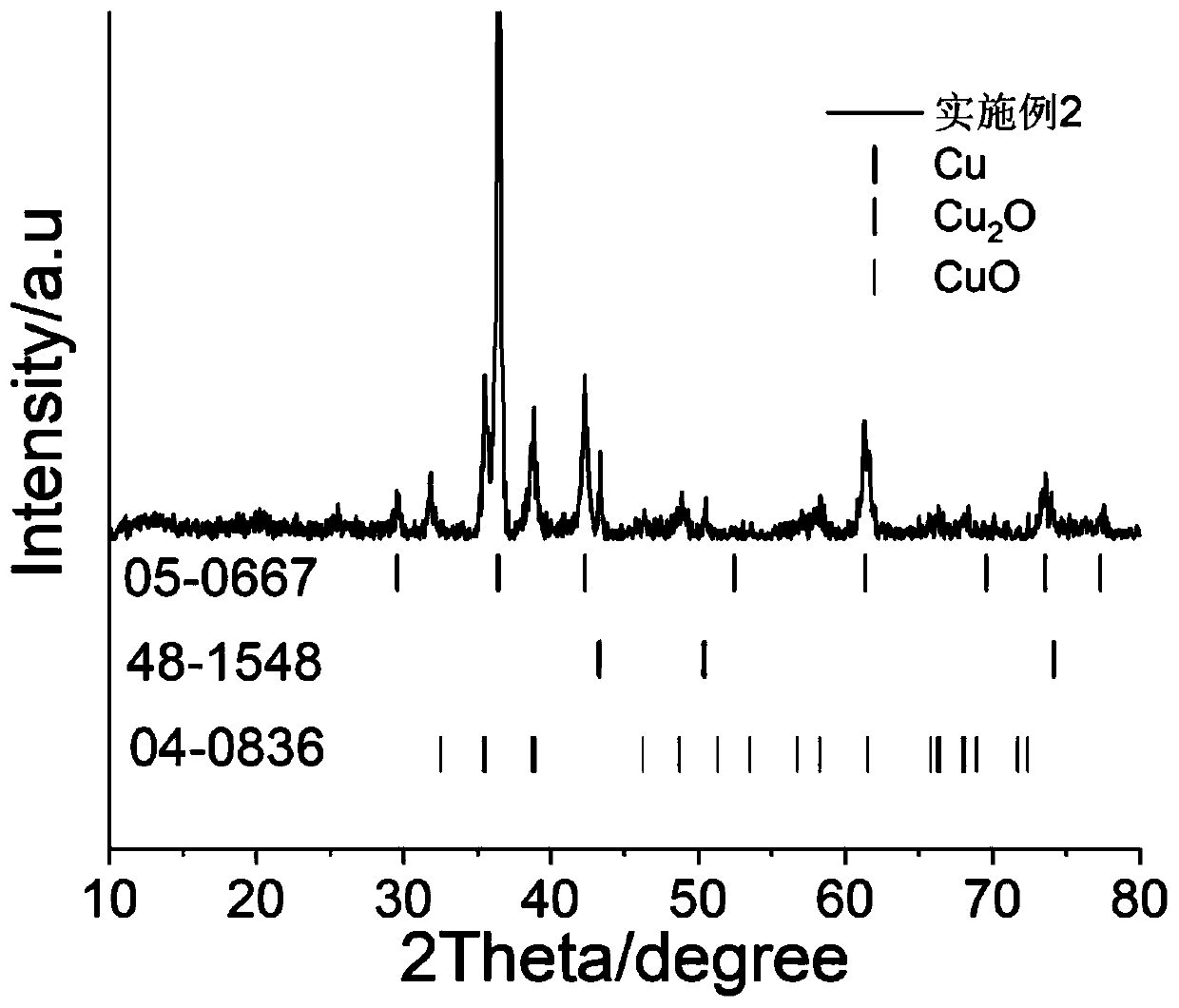

Embodiment 2

[0043] CuO / Cu in this embodiment 2 The preparation method of O / Cu ternary composite material comprises the following steps:

[0044] S1, 2.5g of analytically pure copper sulfate pentahydrate (CuSO 4 "5H 2 O) add 20mL deionized water to prepare a copper sulfate solution with a concentration of 0.5mol / L. Dissolve 0.8 g of analytically pure sodium hydroxide in 20 mL of deionized water to prepare a 1.0 mol / L sodium hydroxide solution.

[0045] S2. Add 2.5g of yeast powder to 20mL of deionized water and cultivate for 40min. After the cultivation, add it to the copper sulfate solution, and then gradually add the above mixed solution to the sodium hydroxide alkali solution to obtain a mixed solution.

[0046] S3. Put the mixed solution obtained in step S2 in a microwave reactor, and react at a temperature of 70° C. for 8 minutes to obtain a reaction solution.

[0047] S4. The reaction solution was centrifuged at 5000 rpm and dried in a drying oven at 80° C. for 12 hours. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com