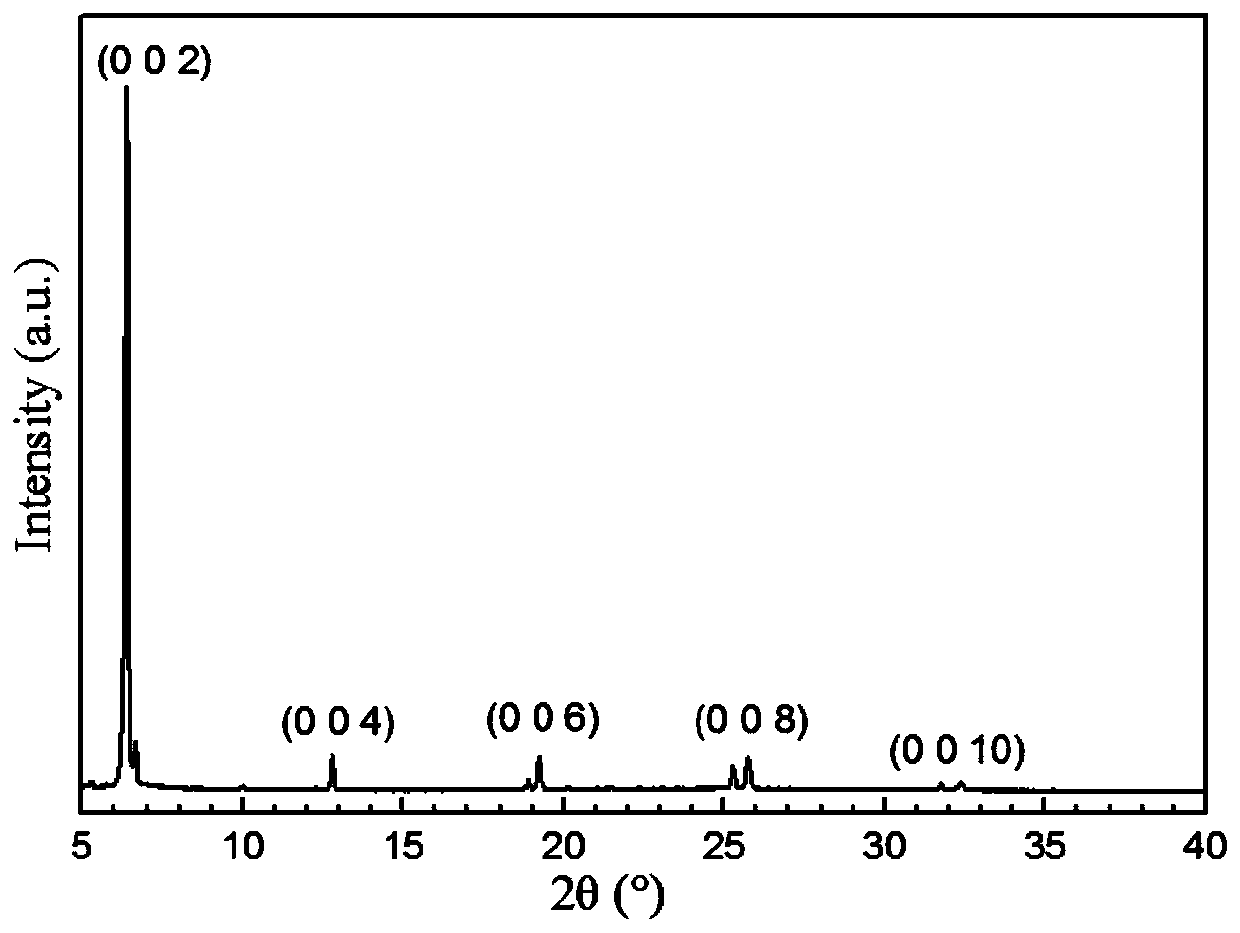

Preparation method of needle-shaped two-dimensional organic-inorganic perovskite (C4H9NH3)2PbI4 micro-nano crystals

An inorganic calcium and organic technology, applied in the field of preparation of micro-nano needle crystals, can solve problems affecting the quality of thin-film crystals and device performance, and achieve the effect of low cost, simple equipment and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

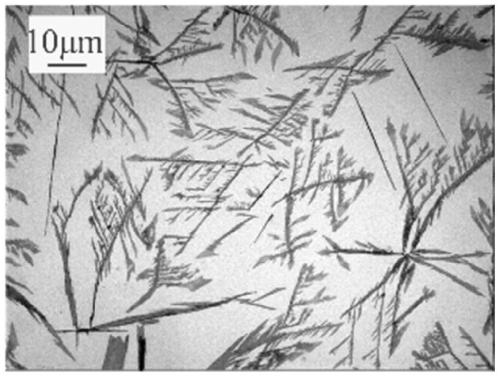

Embodiment 1

[0026] PB 2 Pre-deposition film preparation: weigh 50mg PbI 2 The powder was placed in a vial filled with 1ml of DMF and dissolved by ultrasonic vibration to obtain a light yellow clear solution. Place the glass slide in alcohol, ultrasonically clean it for 15 minutes, take it out, and wash it with N 2 blow dry. Drops of pale yellow PbI 2 Put 1 to 2 drops of the solution on the glass substrate, spread it as evenly as possible, and dry it to get PbI 2 Pre-deposited thin film (thickness 100nm).

[0027] C 4 h 9 NH 3 I precursor solution preparation: weigh 20mg C 4 h 9 NH 3 I powder is placed in a small medicine bottle filled with 1ml isopropanol, dissolved by ultrasonic vibration, and brown clear C is obtained. 4 h 9 NH 3 I precursor solution.

[0028] Acicular (C 4 h 9 NH 3 ) 2 PB 4 Preparation of micro-nano crystals: the pre-deposited PbI 2 Film glass slices cut into 1mm 2 Left and right small pieces of glass, dipped in C 4 h 9 NH 3 I precursor solution...

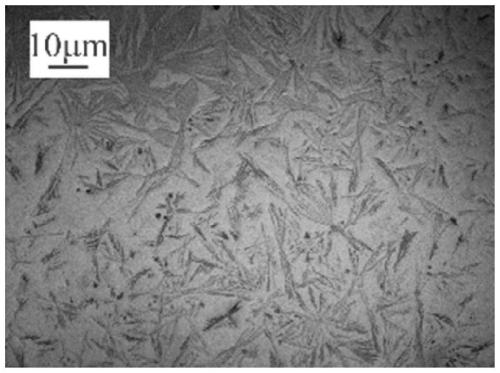

Embodiment 2

[0030] PB 2 Pre-deposition film preparation: weigh 50mg PbI 2 The powder was placed in a vial containing a mixed solution of 0.67ml DMF and 0.33ml toluene, and dissolved by ultrasonic vibration to obtain a light yellow clear solution. Place the glass slide in alcohol, ultrasonically clean it for 15 minutes, take it out, and wash it with N 2blow dry. Preparation of PbI on Glass Lining by Spin Coating 2 For the pre-deposited film, the rotation speed of the spin coater is 1000 rpm, and the time is 30 seconds. Dry to get PbI 2 Pre-deposited thin film (thickness 200nm).

[0031] C 4 h 9 NH 3 I precursor solution preparation: weigh 30mg C 4 h 9 NH 3 I powder is placed in a small medicine bottle filled with 1ml isopropanol, dissolved by ultrasonic vibration, and brown clear C is obtained. 4 h 9 NH 3 I precursor solution.

[0032] Acicular (C 4 h 9 NH 3 ) 2 PB 4 Preparation of micro-nano crystals: the pre-deposited PbI 2 Film glass slices cut into 1mm 2 Left and ...

Embodiment 3

[0034] PB 2 Pre-deposition film preparation: weigh 100mg PbI 2 The powder was placed in a vial containing a mixed solution of 0.67ml DMF and 0.33ml toluene, and dissolved by ultrasonic vibration to obtain a light yellow clear solution. Place the glass slide in alcohol, ultrasonically clean it for 15 minutes, take it out, and wash it with N 2 blow dry. Drops of pale yellow PbI 2 Put 1 to 2 drops of the solution on the glass substrate, spread it as evenly as possible, and dry it to get PbI 2 Pre-deposited thin film (thickness 100nm).

[0035] C 4 h 9 NH 3 I precursor solution preparation: weigh 50mg C 4 h 9 NH 3 I powder is placed in a small medicine bottle filled with 1ml isopropanol, dissolved by ultrasonic vibration, and brown clear C is obtained. 4 h 9 NH 3 I precursor solution.

[0036] Acicular (C 4 h 9 NH 3 ) 2 PB 4 Preparation of micro-nano crystals: the pre-deposited PbI 2 Film glass slices cut into 1mm 2 Left and right small pieces of glass, dipped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com