Waterproof heat-insulation composite board for building and production method

A thermal insulation board, thermal insulation technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of poor waterproof thermal insulation performance, can not be flame retardant and anti-ultraviolet, can not be prefabricated in advance, etc., to achieve good waterproof Thermal insulation performance, not easy to age and decompose, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

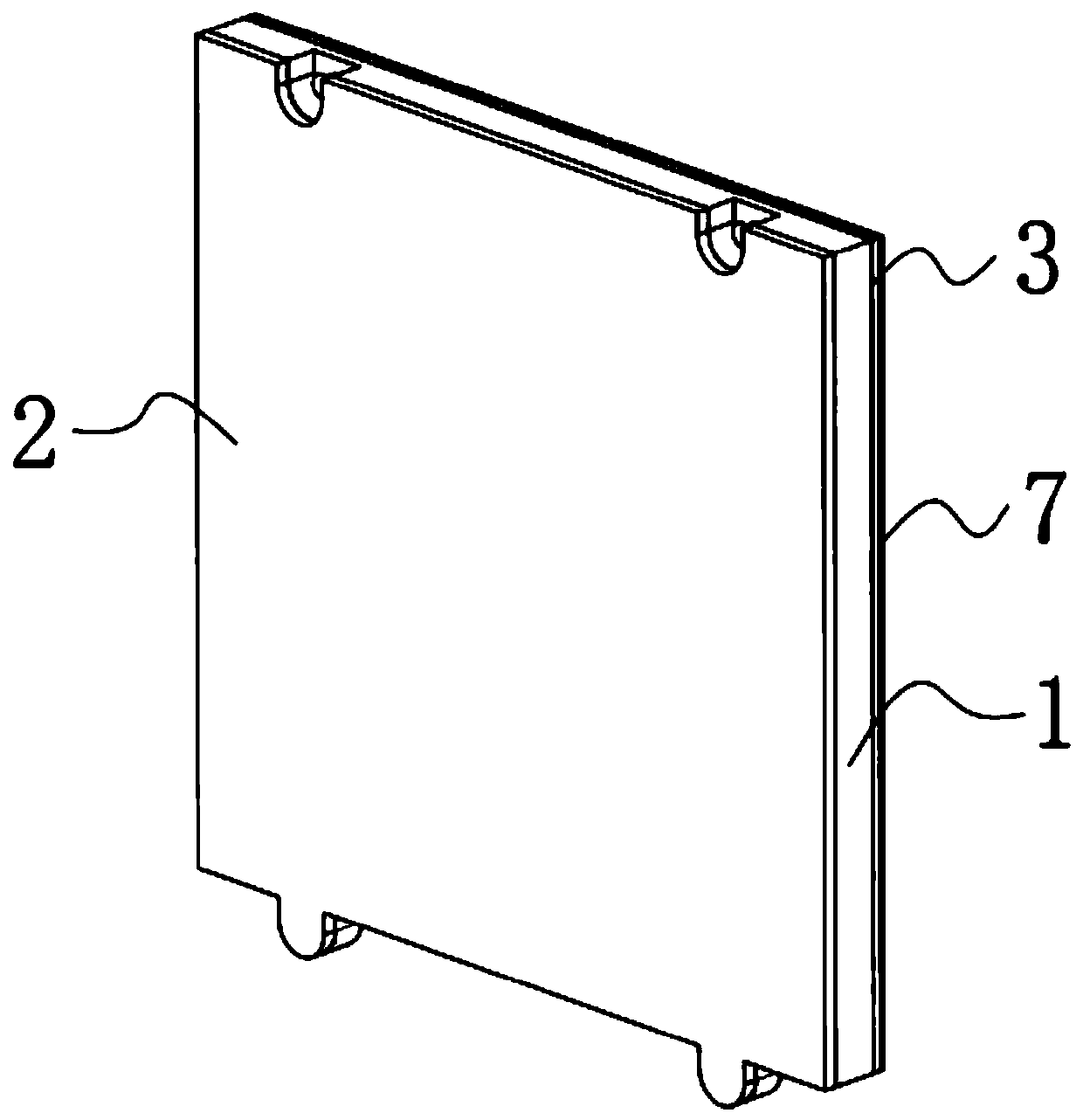

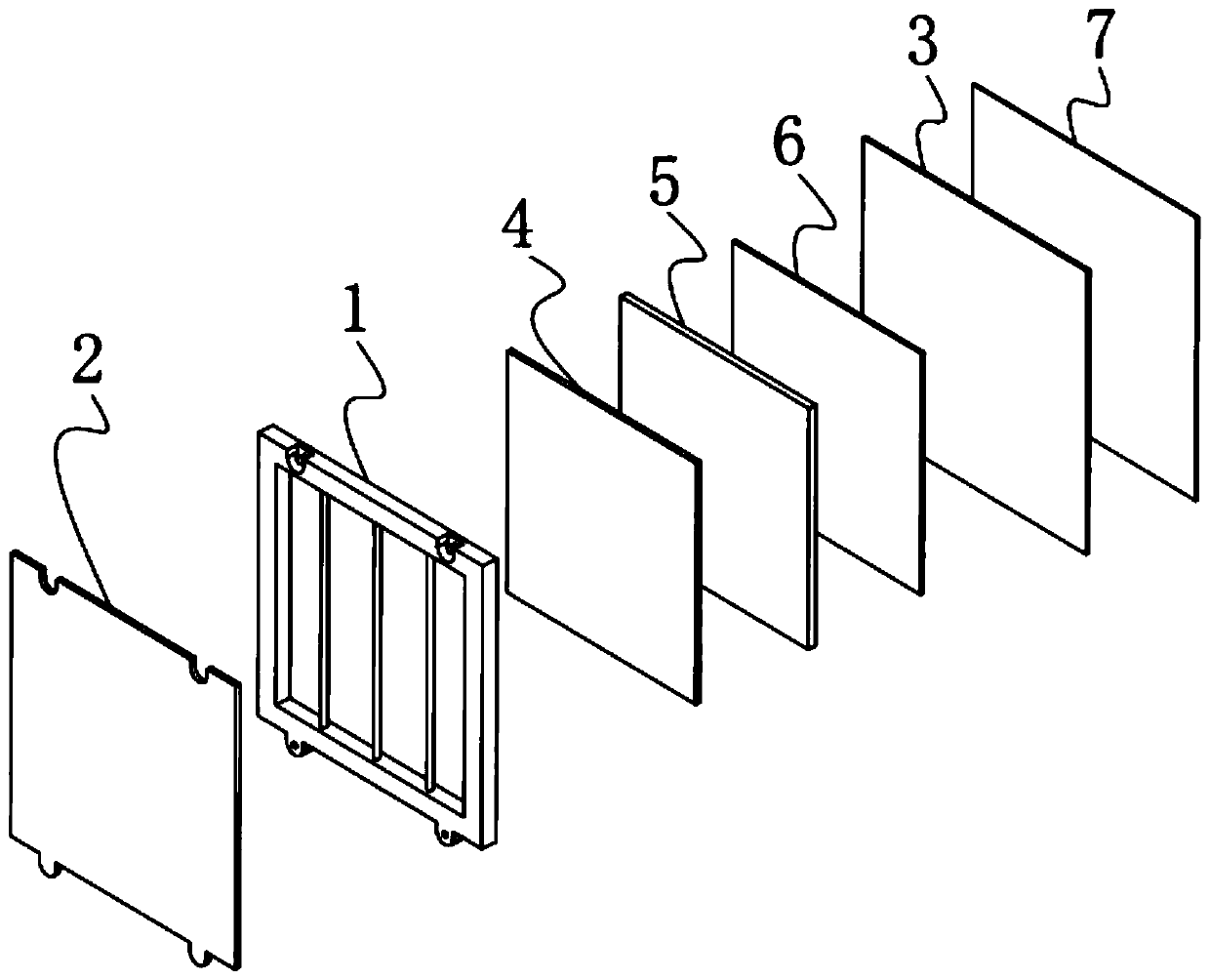

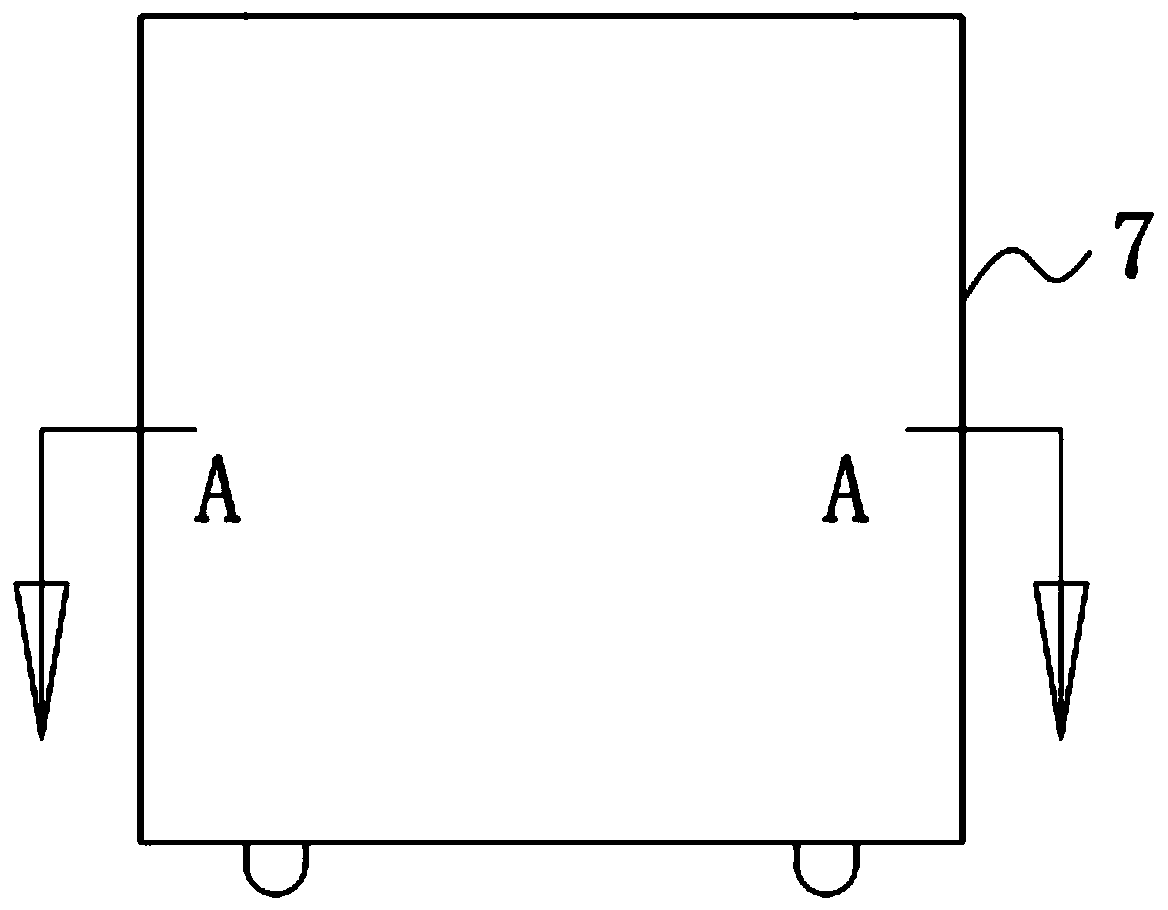

[0063] A building waterproof thermal insulation composite board, such as Figure 1-4 As shown, it includes a square fixed frame 1, the front of the square fixed frame 1 is fixed and sealed with a decorative panel 2 by an adhesive, and the rear of the square fixed frame 1 is fixed and sealed with a mounting plate by an adhesive 3. The inside of the square fixed frame 1 is provided with a first waterproof board 4, a thermal insulation board 5 and a second waterproof board 6 from front to back, and the front of the first waterproof board 4 is bonded to the The back of the decorative panel 2 is fixed and sealed, and the back of the first waterproof board 4 is fixed and sealed with the front of the thermal insulation board 5 through an adhesive, and the rear of the thermal insulation board 5 is fixed and sealed with an adhesive. It is fixed and sealed with the front of the second waterproof board 6 , and the back of the second waterproof board 6 is fixed and sealed with the front o...

Embodiment 2

[0095] The difference from Example 1 is that the production method of the building waterproof thermal insulation composite board comprises the following steps:

[0096] Get the following raw materials and weigh them in parts by weight:

[0097] The first group: 18 parts of polyethylene, 6 parts of carbon black, 4 parts of anti-aging agent, 5 parts of antioxidant, 8 parts of ultraviolet absorber, 4 parts of stabilizer and 10 parts of flame retardant;

[0098] The second group: 25 parts of polystyrene resin, 12 parts of polyurethane, 18 parts of benzene, 10 parts of absolute ethanol, 10 parts of ethylene glycol ether and 11 parts of flame retardant;

[0099] The third group: 35 parts of polyvinyl chloride resin, 10 parts of dioctyl phthalate, 12 parts of tribasic lead sulfate, 14 parts of stearic acid amide, 18 parts of calcium carbonate powder and zinc dialkyl dithiophosphate 14 copies;

[0100] Purchase the following materials:

[0101] Group 4: Purchasing custom-made marbl...

Embodiment 3

[0109] The difference from Example 2 is that the production method of the building waterproof thermal insulation composite board comprises the following steps:

[0110] Get the following raw materials and weigh them in parts by weight:

[0111] The first group: 20 parts of polyethylene, 8 parts of carbon black, 5 parts of anti-aging agent, 6 parts of antioxidant, 10 parts of ultraviolet absorber, 5 parts of stabilizer and 12 parts of flame retardant;

[0112] The second group: 30 parts of polystyrene resin, 15 parts of polyurethane, 20 parts of benzene, 12 parts of absolute ethanol, 12 parts of ethylene glycol ether and 12 parts of flame retardant;

[0113] The third group: 40 parts of polyvinyl chloride resin, 12 parts of dioctyl phthalate, 14 parts of tribasic lead sulfate, 15 parts of stearic acid amide, 20 parts of calcium carbonate powder and zinc dialkyldithiophosphate 15 copies;

[0114] Purchase the following materials:

[0115] Group 4: Purchasing custom-made marbl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com