Silicon-layered titanium carbide cathode material and preparation method thereof

A negative electrode material, titanium carbide technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., to achieve the effect of strong operability, simple process steps, and small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of described silicon-layered titanium carbide negative electrode material that the present invention proposes, comprises the following steps:

[0021] S1. Weigh Ti 3 AlC 2 Powder 10g, add 100g mass concentration and be in the HF solution of 40%, stir for 48 hours and etch, obtain Ti 3 C 2 suspension, the resulting Ti 3 C 2 The suspension is filtered and dried to obtain layered titanium carbide;

[0022] S2. Add nano-silicon particles and layered titanium carbide into ethanol at a weight ratio of 20:80, ultrasonically disperse for 30 minutes to obtain a slurry, filter the obtained slurry, and then dry at 60°C for 24 hours to obtain the silicon-layer titanium carbide anode material.

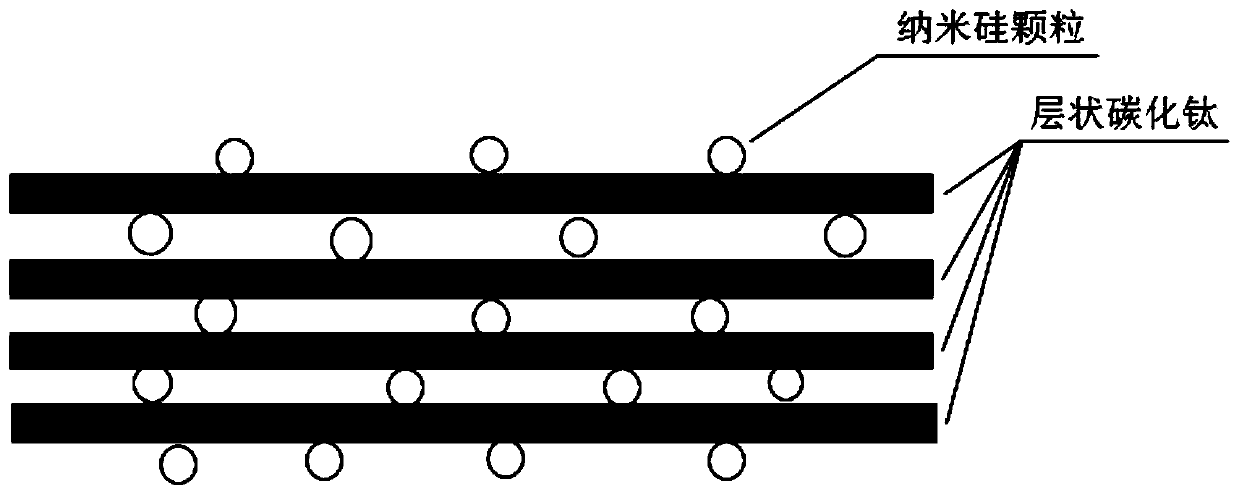

[0023] figure 1 It is a schematic structural view of silicon-layered titanium carbide negative electrode material in Example 1 of the present invention; by figure 1 It can be seen that in the silicon-layered titanium carbide negative electrode material, n...

Embodiment 2

[0028] A kind of preparation method of described silicon-layered titanium carbide negative electrode material that the present invention proposes, comprises the following steps:

[0029] S1. Weigh Ti 3 AlC 2 Powder 10g, add 150g mass concentration and be in the HF solution of 20%, stir 72 hours, prepare the suspension of layered titanium carbide; Then the suspension of layered titanium carbide is filtered, dry, obtain layered titanium carbide;

[0030] S2. Add nano-silicon particles and layered titanium carbide into ethanol at a weight ratio of 5:95, ultrasonically disperse for 5 minutes, filter with suction, and then dry at 105°C for 4 hours to obtain the silicon-layered titanium carbide negative electrode material.

Embodiment 3

[0032] A silicon-layered titanium carbide negative electrode material proposed by the present invention includes silicon particles and layered titanium carbide, and the silicon particles are evenly distributed on the surface and between the sheets of the layered titanium carbide.

[0033] A kind of preparation method of described silicon-layered titanium carbide negative electrode material that the present invention proposes, comprises the following steps:

[0034] S1. Weigh Ti 3 SiC 2 Powder 10g, add 100g mass concentration and be in the HF solution of 50%, stir 24 hours, prepare layered Ti 3 C 2 suspension; then the layered Ti 3 C 2 The suspension was filtered and dried to obtain layered Ti 3 C 2 ;

[0035] S2, the particle size is 30-80nm nano-silicon particles and layered Ti 3 C 2 Add it into ethanol at a weight ratio of 40:60, ultrasonically disperse for 60 minutes, then filter with suction, and dry at 80° C. for 13 hours to obtain the silicon-layered titanium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com