Odour purifying system in livestock and poultry breeding farm and application method thereof

A purification system and farm technology, applied in the field of odor purification systems in livestock and poultry farms, can solve the problems of little improvement in air quality, impact on the breeding industry, and no gas purification, so as to improve the quality of the air environment and protect the environment. The effect of healthy development and elimination of pathogenic bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

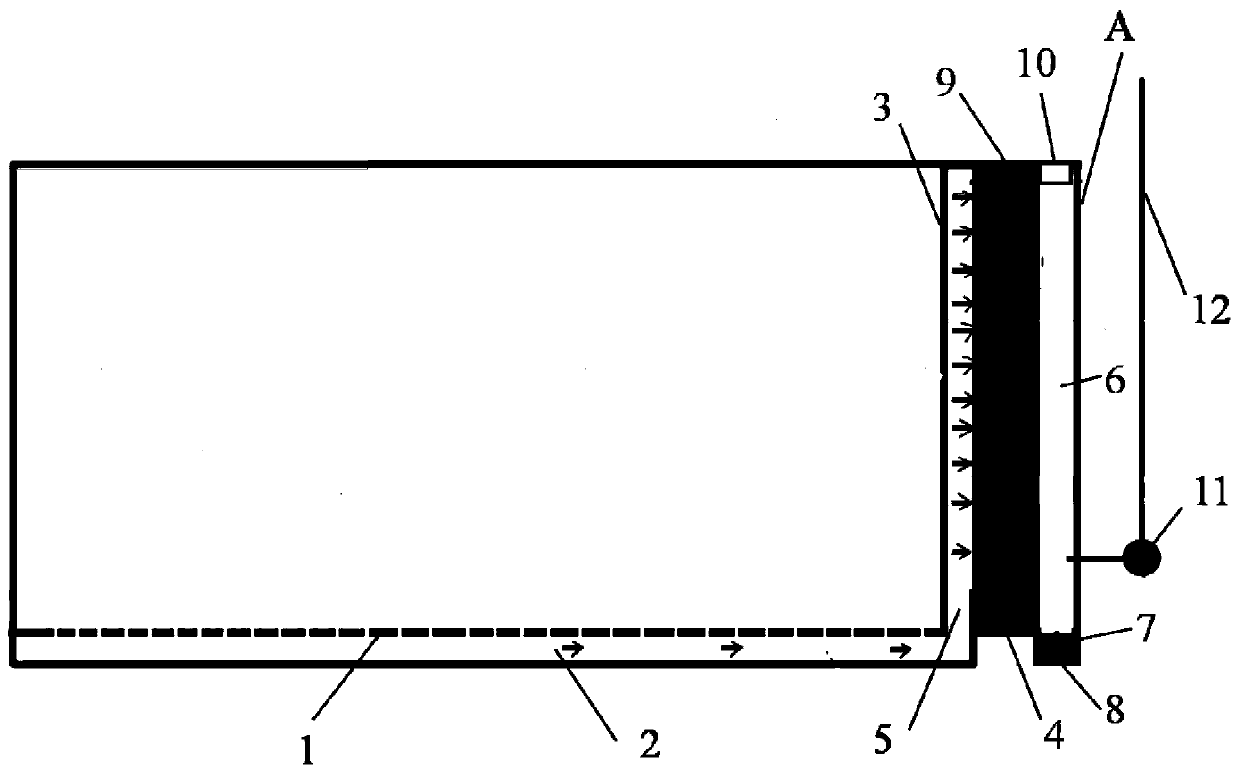

Embodiment 1

[0049] In this embodiment, the height of the porous biological deodorization wall is consistent with that of the livestock and poultry farm, and the thickness of the wall is 96cm. The porous biological deodorization wall of this embodiment is built with interlaced aerated concrete blocks, with a penetrating porosity of 30%, has good air permeability, has the ability to adsorb ammonia nitrogen, organic pollutants, and odor, and has hygroscopicity. , biocompatibility, corrosion resistance.

[0050] The application method of the odor purification system of the present embodiment is as follows:

[0051] Add a spray liquid consisting of aquaculture wastewater and tap water to the storage tank to maintain the ammonia nitrogen concentration in the tank at 1-20mg / L and COD at 40-60mg / L;

[0052] Start the spray water pump, spray the spray liquid to the porous biological deodorization wall, the microorganisms in the spray liquid proliferate and load into the porous biological deodoriz...

Embodiment 2

[0056] In this embodiment, the square wood perforated board is used as the support on both sides of the porous biological deodorization wall, and the middle is filled with broken particles of zeolite aerated concrete, with a particle size of 30-200 mm, to construct a porous biological deodorization wall with a thickness of 48 cm and through pores. The rate is 40-45%. It has good air permeability, has the ability to adsorb ammonia nitrogen, organic pollutants, and odor, and has hygroscopicity, biocompatibility, and corrosion resistance.

[0057] The application method of the odor purification system of the present embodiment is as follows:

[0058] Add a spray liquid composed of aquaculture wastewater and tap water into the storage tank to maintain the ammonia nitrogen concentration in the tank at 2-5mg / L and COD at 40-60mg / L;

[0059] Start the spray water pump, spray the spray liquid to the porous biological deodorization wall, the microorganisms in the spray liquid prolifera...

Embodiment 3

[0063] In this embodiment, the square wood perforated board is used as the support on both sides of the porous biological deodorization wall, and the middle is filled with aerobically fermented woody particles with a particle size of 10-100mm to construct a porous biological deodorization wall with a thickness of 20cm and good penetration. The porosity is 35-40%. It has good air permeability, the ability to adsorb ammonia nitrogen, organic pollutants, and odor, and has hygroscopicity, biocompatibility, and corrosion resistance.

[0064] The application method of the odor purification system of the present embodiment is as follows:

[0065] Add a spray liquid composed of aquaculture wastewater and tap water into the storage tank to maintain the ammonia nitrogen concentration in the tank at 2-5mg / L and COD at 40-60mg / L;

[0066] Start the spray water pump, spray the spray liquid to the porous biological deodorization wall, the microorganisms in the spray liquid proliferate and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com