Reactive super-hydrophobic TiO2 microsphere and preparation method and application thereof

A super-hydrophobic and reactive technology, which is applied in the preparation of microspheres, microcapsule preparations, wear-resistant fibers, etc., can solve the problems of performance degradation, easy drop of nanoparticles, poor friction resistance and durability, etc., and prolong the service life , low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of hybrid titanium sol: Weigh 150.0g of hydrochloric acid (1mol / L) and 55.0g of deionized water and mix to form component A; weigh 80.0g of tetra-n-butyl titanate and 20.0g of absolute ethanol, Stir mechanically at 150r / min for 3 minutes to evenly prepare component B;

[0045] (2) Add component B and component A dropwise to the ethanol solution at room temperature at 25°C at a rate of 2 drops / second to prepare a titanium sol until components A and B are completely added to 100.0 g of ethanol aqueous solution ;

[0046] (3) Add ammoniacal liquor (1mol / L) dropwise to adjust the pH of the system to 4;

[0047] (4) Measure 100mL of titanium dioxide sol at 25°C, add 4mL of octyltriethoxysilane (OTES), and react for 4h; then add 4mL of γ-glycidyl etheroxypropyltrimethoxysilane (KH560), and react for 4h, Stir mechanically at a speed of 500r / min to complete the modification of titanium dioxide;

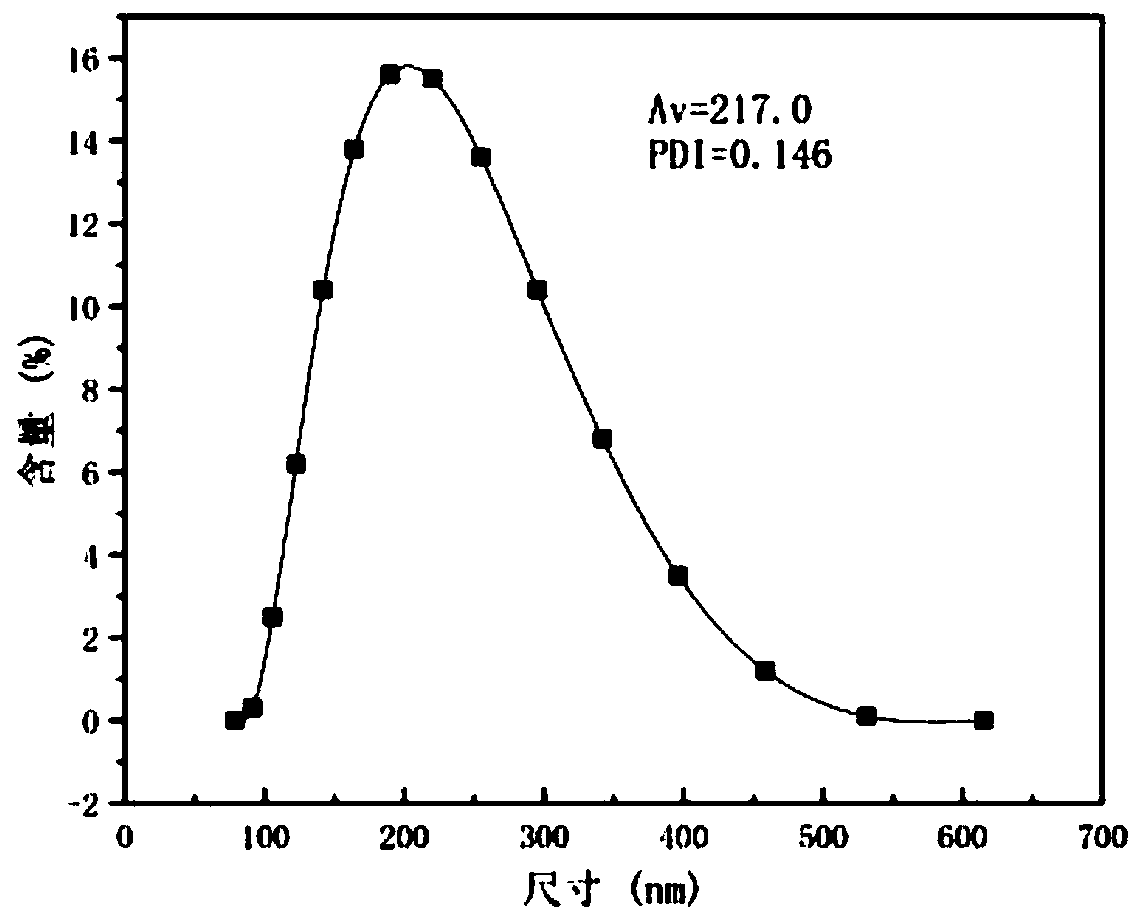

[0048] (5) Use a centrifuge to centrifuge the titanium sol at 1...

Embodiment 2

[0050](1) Preparation of hybrid titanium sol: Weigh 150.0g of hydrochloric acid (1mol / L) and 55.0g of deionized water and mix to form component A; weigh 80.0g of tetra-n-butyl titanate and 20.0g of absolute ethanol, Stir mechanically at 150r / min for 3 minutes to evenly prepare component B;

[0051] (2) Add component B and component A dropwise to the ethanol solution at room temperature at 25°C at a rate of 2 drops / second to prepare a titanium sol until components A and B are completely added to 100.0 g of ethanol aqueous solution ;

[0052] (3) Add ammoniacal liquor (1mol / L) dropwise to adjust the pH of the system to 4;

[0053] (4) Measure 100mL of titanium dioxide sol at 25°C, add a mixture of 2mL of dodecyltriethoxysilane (DTEOS) and 2mL of γ-chloropropyltriethoxysilane (CPTS), and react for 4 hours; then add 4mL of γ -glycidyl etheroxypropyltrimethoxysilane (KH560), reacted for 4h, and mechanically stirred at a speed of 500r / min to complete the modification of titanium d...

Embodiment 3

[0056] (1) Preparation of hybrid titanium sol: Weigh 150.0g hydrochloric acid (1mol / L) and 55.0g deionized water, mix and make component A; weigh 80.0g tetra-n-butyl titanate and 20.0g absolute ethanol, Stir mechanically at 150r / min for 3 minutes to evenly prepare component B;

[0057] (2) Add component B and component A dropwise to the ethanol solution at room temperature at 25°C at a rate of 2 drops / second to prepare a titanium sol until components A and B are completely added to 100.0 g of ethanol aqueous solution ;

[0058] (3) Add ammoniacal liquor (1mol / L) dropwise to adjust the pH of the system to 4;

[0059] (4) Measure 100mL of titanium sol at 25°C, add 4mL of methyltriethoxysilane (MTES), and react for 4h; then add 4mL of γ-glycidyl etheroxypropyltrimethoxysilane (KH560), and react for 4h, Stir mechanically at a speed of 500r / min to complete the modification of titanium dioxide;

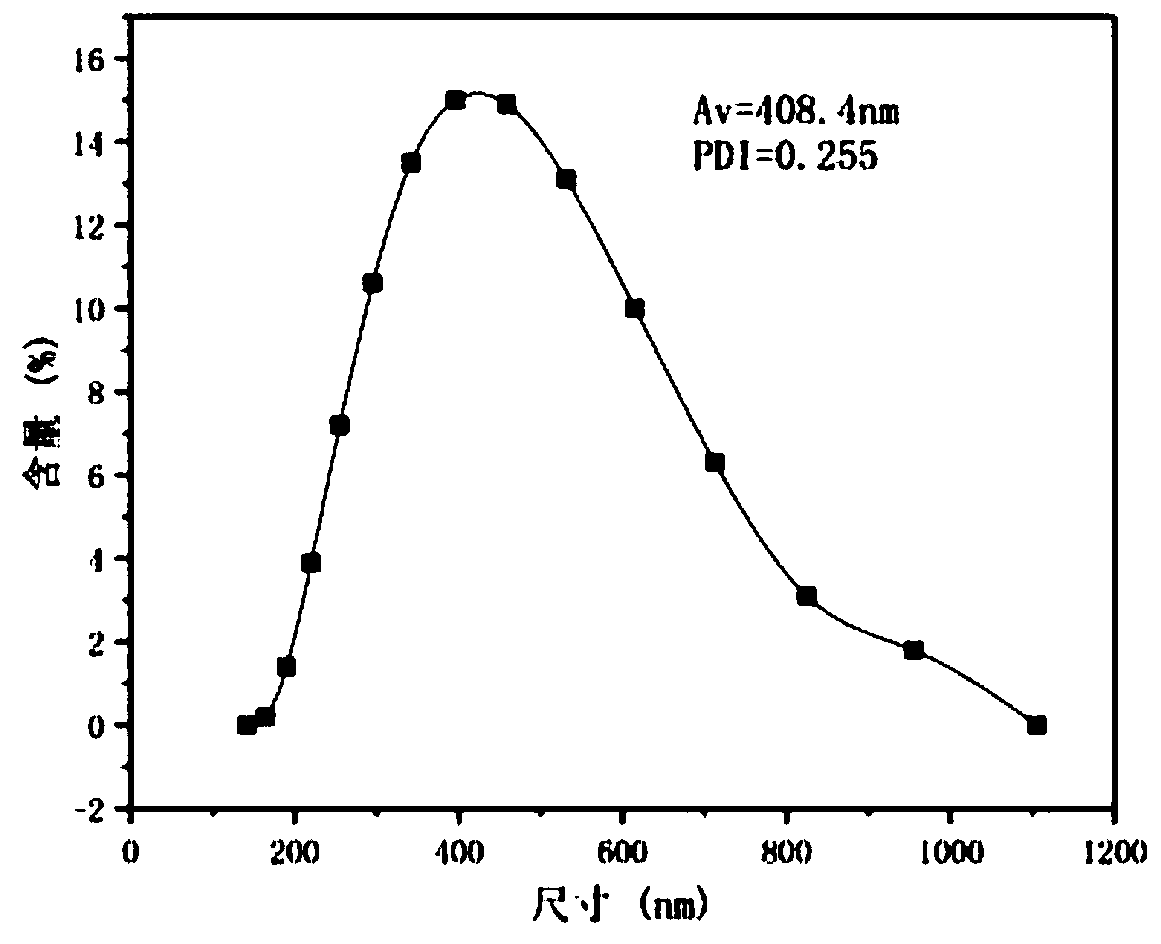

[0060] (5) Use a centrifuge to centrifuge the titanium sol at 1000r / min for 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com