A functionalized zirconium-based metal-organic framework/graphene oxide composite material and its preparation method and application

An organic framework and composite material technology, applied in the field of materials science and engineering, can solve the problems that limit the wide application of graphene oxide and its composite materials, high impurity content of product materials, and reduced specific surface area, so as to achieve fast adsorption rate and aromatic Excellent family structure and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

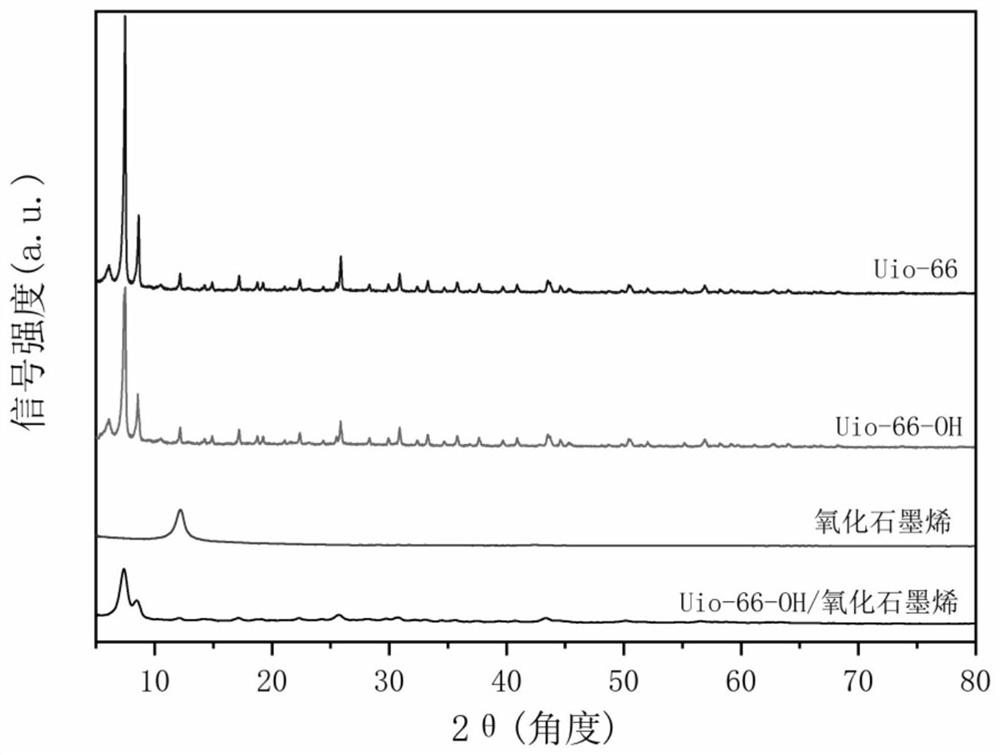

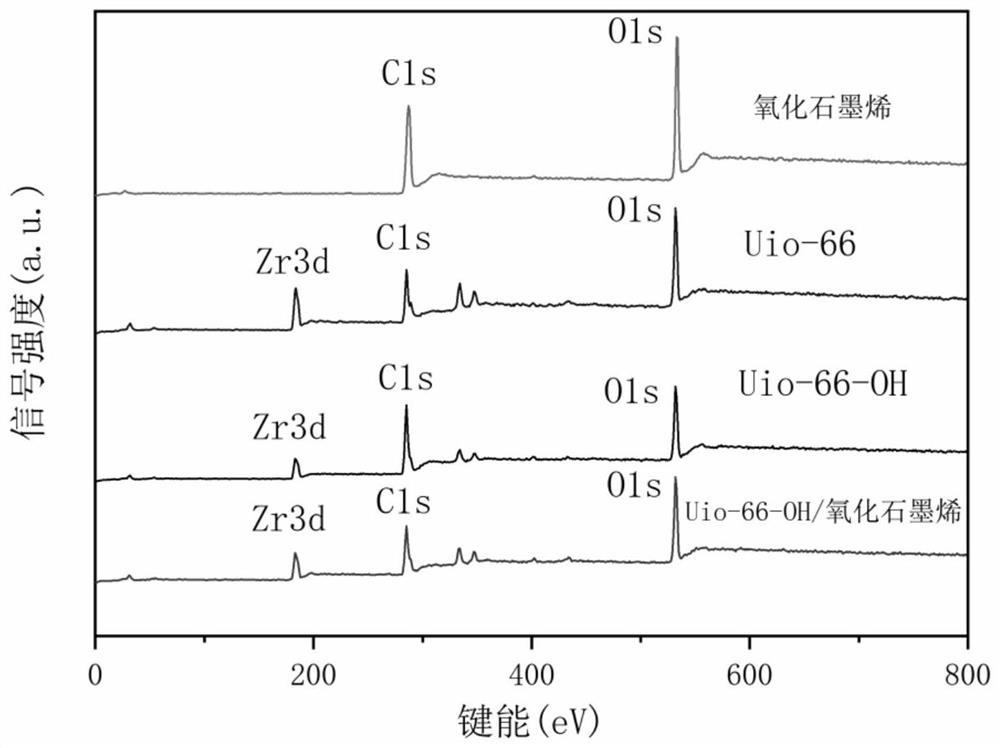

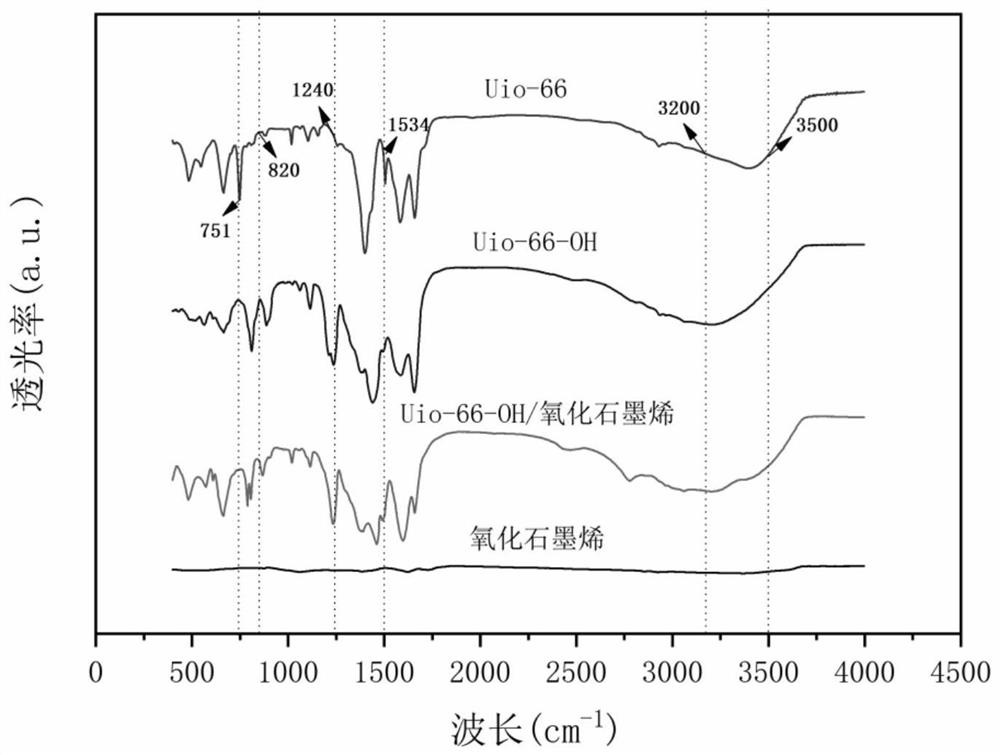

[0040] A functionalized zirconium-based metal-organic framework / graphene oxide composite material, the composite material uses a functionalized zirconium-based metal-organic framework as a carrier, and the functionalized zirconium-based metal-organic framework is doped with graphene oxide, wherein the functionalized zirconium-based The metal organic framework is Uio-66-OH.

[0041] In this example, the mass percentage of graphene oxide in the functionalized zirconium-based MOF / graphene oxide composite material is 0.884%.

[0042] A preparation method of the functionalized zirconium-based metal-organic framework / graphene oxide composite material in the above-mentioned embodiment of the present invention, comprising the following steps:

[0043] (1) Weigh 1.400g of 2,5-dihydroxyterephthalic acid (organic ligand) and add it to 40mL N,N-dimethylformamide (high boiling point organic solvent). Stir at 300r / min for 5min to completely dissolve 2,5-dihydroxyterephthalic acid in N,N-di...

Embodiment 2

[0068] Application of a functionalized zirconium-based metal-organic framework / graphene oxide composite material in the treatment of dye wastewater, specifically using the functionalized zirconium-based metal-organic framework / graphene oxide composite material (Uio-66- OH / graphene oxide) to process methylene blue wastewater, comprising the following steps:

[0069] Take the functionalized zirconium-based metal-organic framework / graphene oxide composite material (Uio-66-OH / graphene oxide) prepared in Example 1, the zirconium-based metal-organic framework material (Uio-66-OH / graphene oxide) prepared in Comparative Example 1 ), the functionalized zirconium-based metal-organic framework (Uio-66-OH) prepared in Comparative Example 2, each 25 mg, was added to 50 mL of methylene blue wastewater with a concentration of 20 mg / L, and was shaken rapidly to make the adsorbent fully Disperse in wastewater so that the adsorbent can be fully dispersed in methylene blue wastewater, fix it in ...

Embodiment 3

[0074] Application of a functionalized zirconium-based metal-organic framework / graphene oxide composite material in the treatment of dye wastewater, specifically using the functionalized zirconium-based metal-organic framework / graphene oxide composite material (Uio-66- OH / graphene oxide) to process methylene blue wastewater, comprising the following steps:

[0075] Take 50 mg of the functionalized zirconium-based metal-organic framework / graphene oxide composite (Uio-66-OH / graphene oxide) prepared in Example 1 and add it to 100 mL of methylene blue wastewater with a concentration of 20 mg / L, and shake it rapidly The adsorbent is fully dispersed in the wastewater, so that the adsorbent can be fully dispersed in the methylene blue wastewater, placed on a magnetic stirrer, and adsorbed at 25°C and 300r / min for 1 hour to complete the treatment of methylene blue in the wastewater.

[0076] During the adsorption process, when the adsorption time is 1min, 3min, 5min, 8min, 10min, 15mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com