Environment-friendly kitchen waste continuous treatment device and method

A kitchen waste and processing device technology, which is applied in the field of environment-friendly kitchen waste continuous processing devices, can solve the problems of limited landfill storage space, potential health and safety hazards, and high moisture content, and achieve resource utilization and zero waste discharge. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

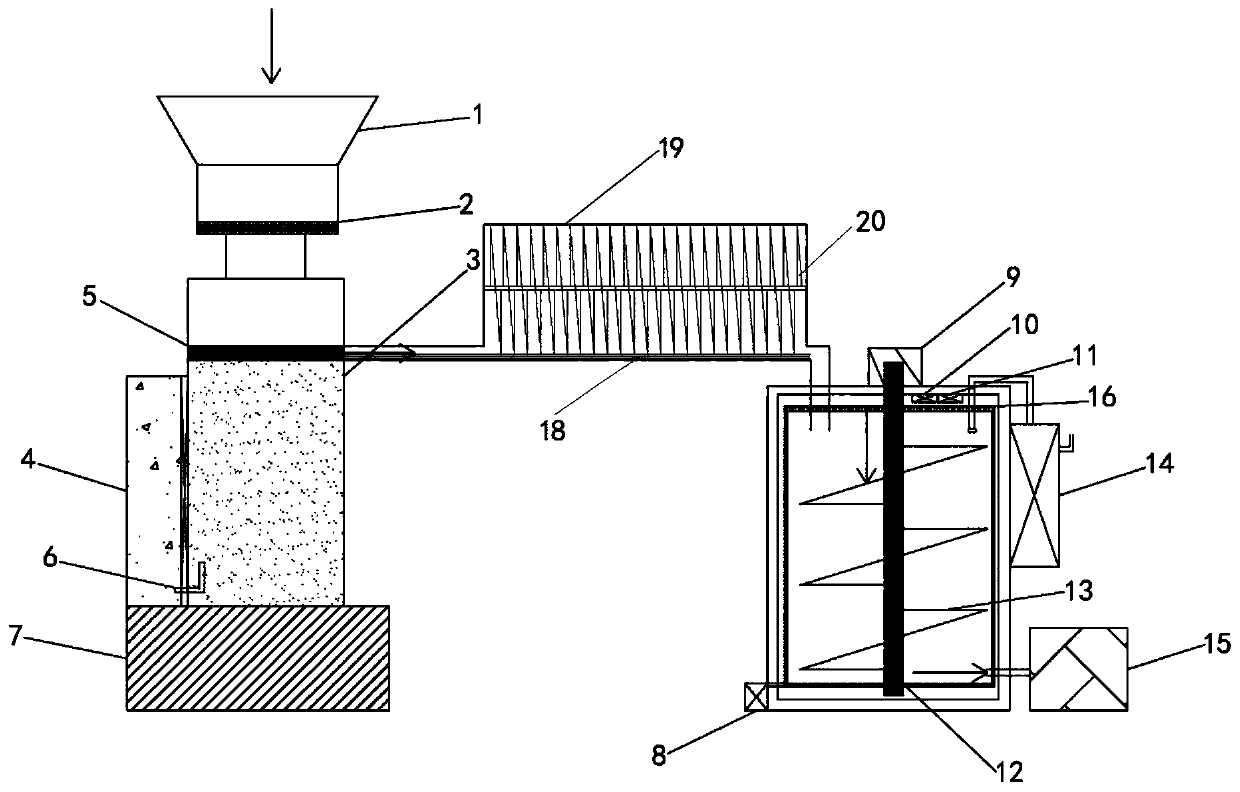

[0034] An environment-friendly continuous treatment device for food waste, including pretreatment equipment, a main reactor and exhaust gas treatment equipment connected in sequence, wherein:

[0035]Pretreatment equipment includes solid filtering device, oil-water separation device and organic waste crushing device. The feed end of the solid filter device is connected to the feed device 1, the oil-water separation device is installed under the solid filter device, the organic waste crushing device is installed at the discharge end of the solid filter device, and the outlet end of the organic waste crushing device is connected to the main reactor. feed pipe. The solid filtering device comprises an inert solid filter 2 and a solid-liquid separation screen 5, the front end of the inert solid filter 2 is connected to the feeding device 1, and the solid-liquid separation screen 5 is installed below the inert solid filter 2, and the solid-liquid separation screen 5 It is installed...

Embodiment 2

[0045] A small restaurant produces about 500kg of kitchen waste every day. First, the glass, plastic, wood and scrap metal in it are separated from the organic waste through an inert solid filter device, and the oil and water in the liquid are separated through an oil-water separation system. The organic waste is crushed by the waste crushing system and enters the main reactor for 8 hours of aerobic fermentation. The aeration device continuously supplies oxygen to the reactor so that the oxygen concentration in the reactor is maintained at around 10%. The system adjusts and maintains the temperature of the reactor at 65°C, and controls the humidity in the reactor at 30% through the humidity control system. Finally, the volume of waste after aerobic fermentation is reduced by 50%, and organic fertilizers are produced to realize resource utilization. , A small amount of waste gas produced by the reaction is collected and treated by the tail gas treatment system, and then discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com