Technology of synthesizing tert-amyl alcohol based on catalytic distillation solvent method

A technology of catalytic distillation and catalytic distillation column, which is applied in the field of hydration to generate tert-amyl alcohol based on the catalytic distillation of C5 fractions by solvent method, can solve the problems of poor tert-pentene conversion rate and reaction selectivity, etc., so as to reduce energy consumption and improve reaction selectivity. The effect of sex, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

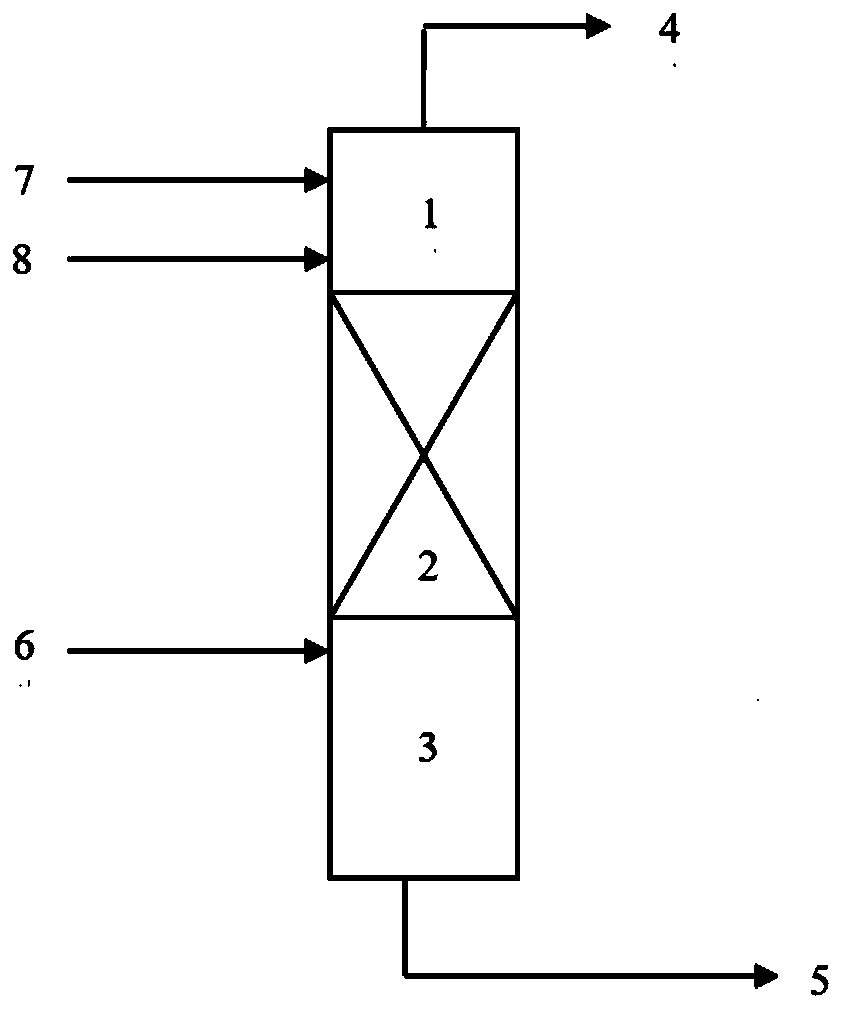

[0034] see figure 1 As shown in the process flow diagram, the process for synthesizing tert-amyl alcohol based on the catalytic distillation solvent method described in this embodiment is a C5 fraction and water with a tert-amylene content of 40% (m / m) as raw materials, and ethylene glycol Butyl ether is the solvent, with DOO6 as the catalyst of the hydration reaction; wherein, the control space velocity is 0.50h -1 , Ethylene glycol butyl ether: water (v / v) = 3: 1, water: tert-amylene (mol) = 5: 1, reaction zone temperature 61-64 ° C, pressure 0.27 MPa, reflux ratio R=2, carry out hydration reaction.

[0035] After the reaction, gas chromatographic analysis showed that the content of tert-amylene in the top C5 fraction was 6.8% (m / m), and the content of tert-amyl alcohol in the bottom product was 17.95% (m / m). The conversion of tert-amylene was calculated to be 89%, and the selectivity to tert-amyl alcohol was 99.2%.

Embodiment 2

[0037] see figure 1 As shown in the process flow diagram, the process for synthesizing tert-amyl alcohol based on the catalytic distillation solvent method described in this embodiment is a C5 fraction and water with a tert-amylene content of 40% (m / m) as raw materials, and ethylene glycol Butyl ether is the solvent, and DOO6 is the catalyst of the hydration reaction; wherein, the control space velocity is 1.0h -1 , Ethylene glycol butyl ether: water (v / v) = 4: 1, water: tert-amylene (mol) = 5: 1, reaction zone temperature 65-68 ° C, pressure 0.32 MPa, reflux ratio R=2, carry out hydration reaction.

[0038] After the reaction finished, it was known through gas chromatography analysis that the content of tert-amylene in the top C5 cut was 11.2% (m / m), and the content of tert-amyl alcohol in the tower bottom product was 15.53% (m / m). The conversion of tert-amylene was calculated to be 81%, and the selectivity to tert-amyl alcohol was 99.5%.

Embodiment 3

[0040] see figure 1 As shown in the process flow diagram, the process for synthesizing tert-amyl alcohol based on the catalytic distillation solvent method described in this embodiment is a C5 fraction and water with a tert-amylene content of 40% (m / m) as raw materials, and ethylene glycol Butyl ether is the solvent, and DOO6 is the catalyst of the hydration reaction; wherein, the control space velocity is 1.0h -1 , Ethylene glycol butyl ether: water (v / v) = 5: 1, water: tert-amylene (mol) = 5: 1, reaction zone temperature 65-68 ° C, pressure 0.32 MPa, reflux ratio R=2, carry out hydration reaction.

[0041] After the reaction finished, it was known through gas chromatography analysis that the content of tert-amylene in the top C5 cut was 11.2% (m / m), and the content of tert-amyl alcohol in the tower bottom product was 15.53% (m / m). The conversion of tert-amylene was calculated to be 81%, and the selectivity to tert-amyl alcohol was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com