A method for analyzing and separating 2,4-dicyano-3-isobutylglutaramide by high performance liquid chromatography

A technology of isobutylglutaramide and high performance liquid chromatography, applied in the field of analytical chemistry, to achieve the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for analyzing and separating 2,4-dicyano-3-isobutylglutaramide by high performance liquid chromatography, comprising the following steps:

[0032] (1) Chromatographic conditions: high performance liquid chromatography: Diana: UltiMate3000; column: SB-CN (250mm×4.6mm); mobile phase: acetonitrile: water = 40:60, adjust the pH to 6; flow rate: 1.0ml / min; Detection wavelength: 205nm; Column temperature: 25°C;

[0033] (2) Take the sample containing 2,4-dicyano-3-isobutylglutaramide, dissolve the sample with mobile phase, and prepare the concentration of 2,4-dicyano-3-isobutylglutaramide 2.5mg / ml sample solution;

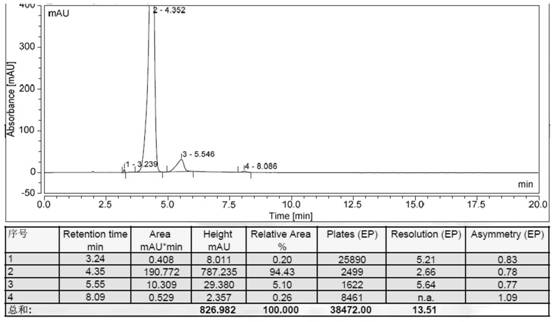

[0034] (3) Get 10 μ l of the obtained sample solution of step (2) and inject it into a high-performance liquid chromatograph to complete the analysis and separation of 2,4-dicyano-3-isobutylglutaramide (results are shown in the appendix figure 1 ).

Embodiment 2

[0036] Instruments and Conditions

[0037] High-performance liquid chromatography: Dianne: UltiMate3000;

[0038] Chromatographic column: SB-CN (250mm×4.6mm);

[0039] Mobile phase: methanol: water = 40:60, adjust the pH to 6;

[0040] Flow rate: 1.0ml / min;

[0041] Detection wavelength: 205nm;

[0042] Column temperature: 25°C;

[0043] Injection volume: 10 μl.

[0044] Experimental procedure

[0045] (1) Weigh 50mg of 2,4-dicyano-3-isobutylglutaramide, place it in a 20ml volumetric flask, add mobile phase to dissolve and dilute to the mark, shake well, and use it as a sample solution;

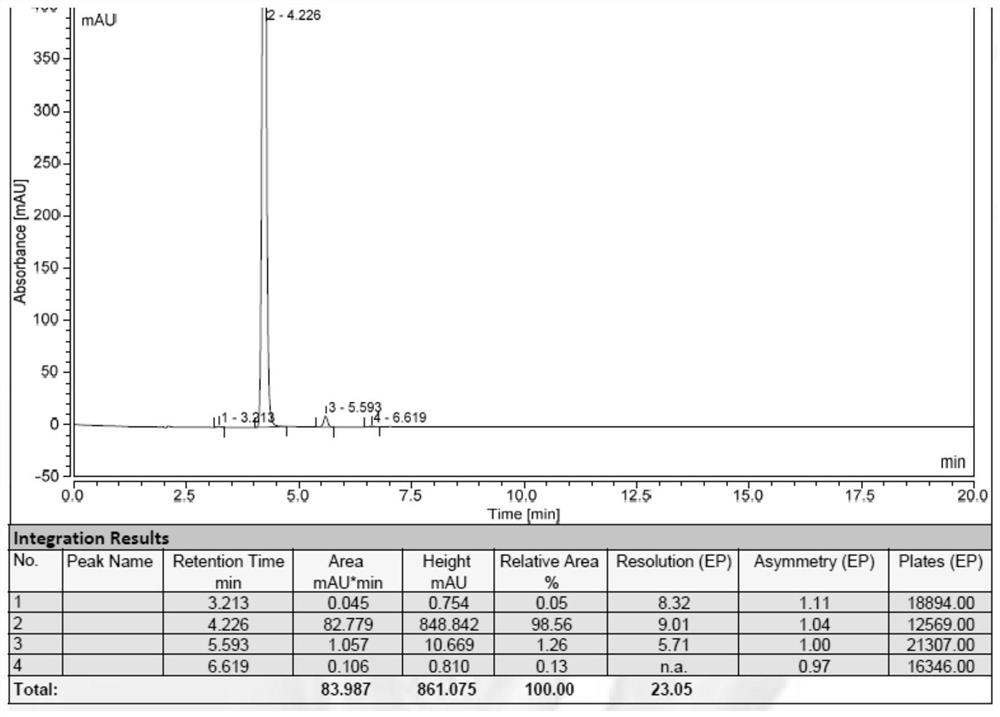

[0046] (2) Take the sample solution, carry out high-performance liquid chromatography analysis according to the above conditions, and record the chromatogram. see attached results figure 2 , figure 2 Peak No. 1 is 2,4-dicyano-3-isobutylglutaramide, and peak No. 2 is impurity. It can be seen that 2,4-dicyano-3-isobutylglutaramide and impurities are well separated. And the main peak ...

Embodiment 3

[0048] Instruments and Conditions

[0049] High-performance liquid chromatography: Dianne: UltiMate3000;

[0050] Chromatographic column: SB-CN (250mm×4.6mm);

[0051] Mobile phase: acetonitrile: water = 30:70, adjust the pH to 6;

[0052] Flow rate: 1.0ml / min;

[0053] Detection wavelength: 205nm;

[0054] Column temperature: 35°C;

[0055] Injection volume: 10 μl.

[0056] Experimental procedure

[0057] (1) Weigh 50mg of 2,4-dicyano-3-isobutylglutaramide, put it in a 20ml volumetric flask, add mobile phase to dissolve and dilute to the mark, shake well, and use it as the sample solution.

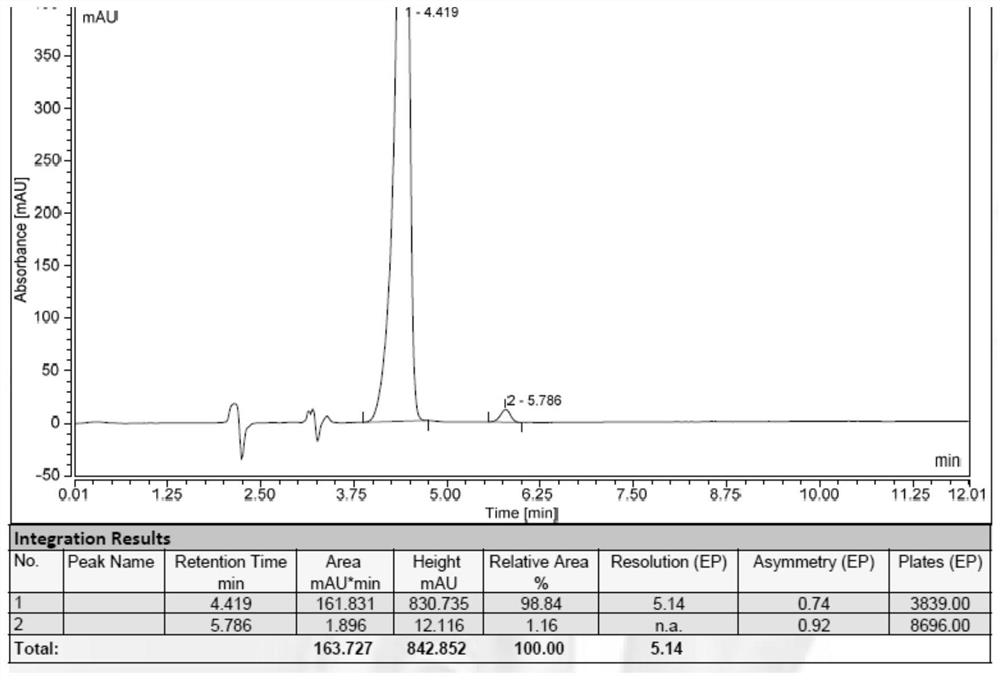

[0058] (2) Take the sample solution, carry out high-performance liquid chromatography analysis according to the above conditions, and record the chromatogram. see attached results image 3 , image 3 Peak No. 1 is an impurity peak, peak No. 2 is cyanoacetamide, peak No. 3 is 2,4-dicyano-3-isobutylglutaramide, and peak No. 4 is an impurity peak. It can be seen that under this con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com