Device for continuously growing carbon nanotubes and method adopting method

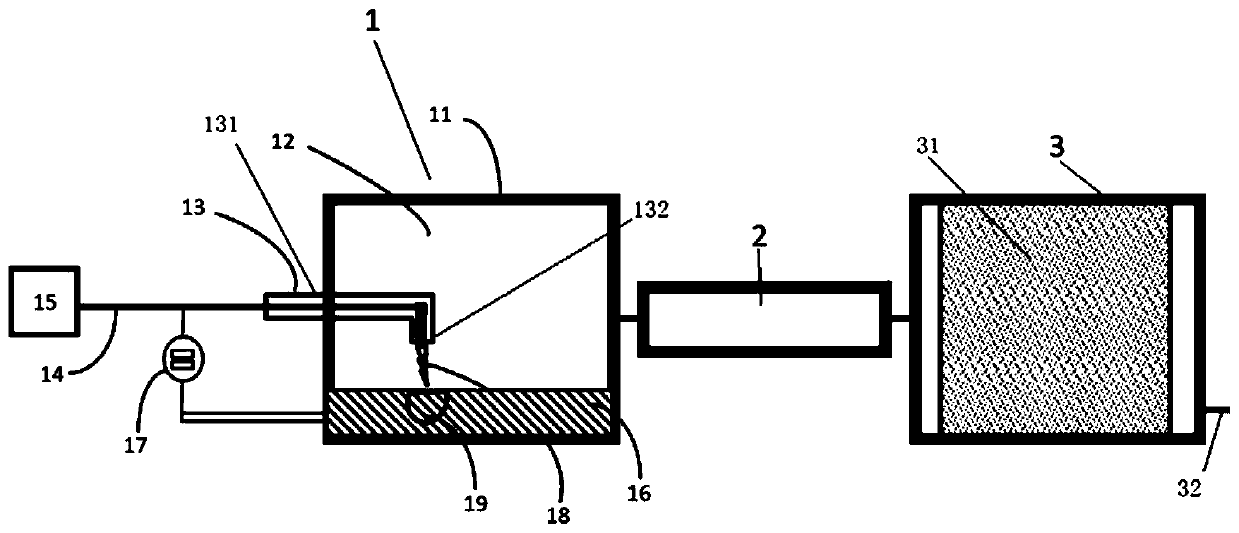

A technology of carbon nanotubes and carbon sources, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve problems such as difficult industrialized batch production, reduce production efficiency, increase the overall energy consumption of the arc system, and prevent anode The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

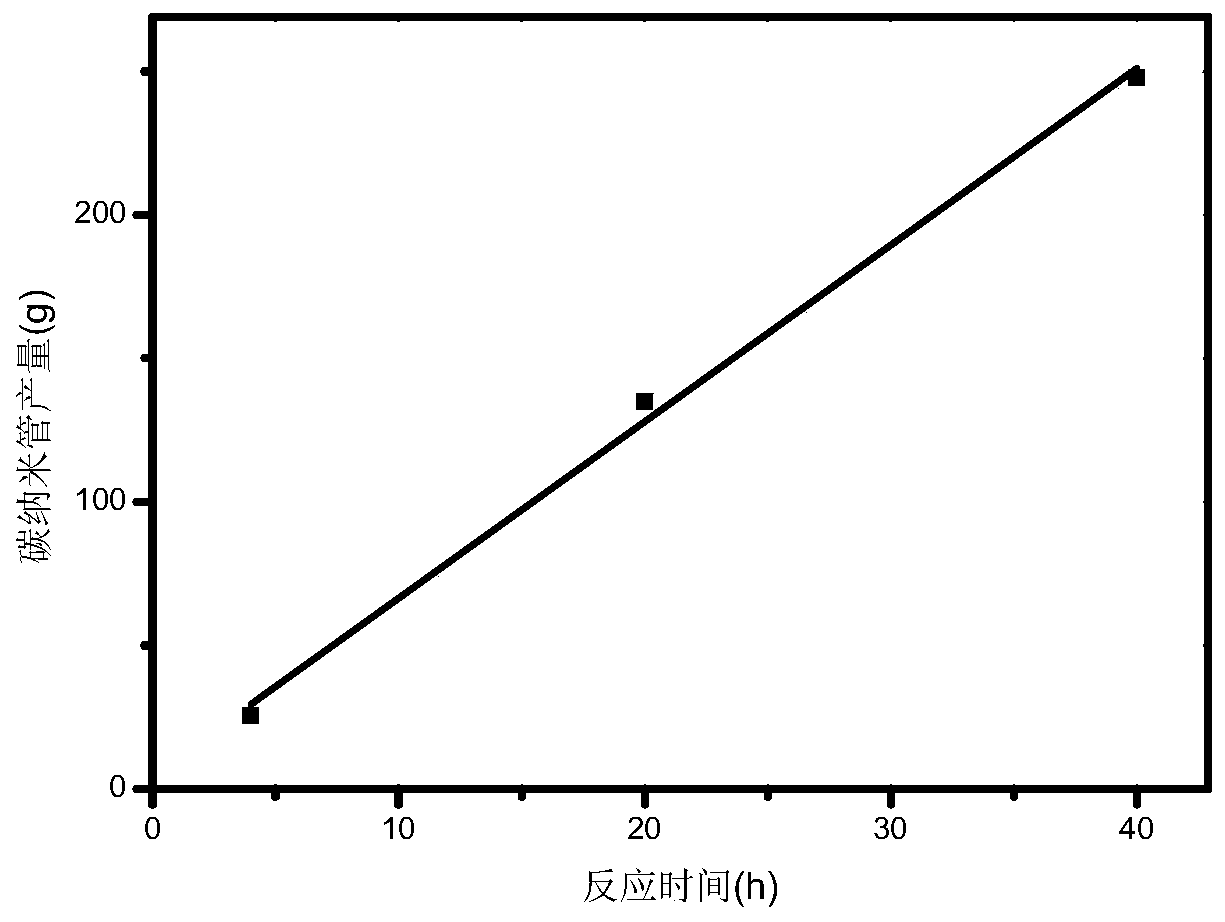

[0048] Pump the vacuum of the whole device to 5 Pa, turn off the vacuum pump, fill in 300 Torr argon gas from the hollow air intake path, turn on the power of the arc welding device, adjust the current to 200 A to trigger the arc, turn on the vacuum pump again, and enter the air from the hollow Add argon and methane to the gas circuit at a total flow rate of 750 sccm (flow rate ratio 2:1), adjust the exhaust valve of the system to maintain the vacuum degree of the arc chamber at 60000 Pa, and turn off the arc welding power supply after the reaction lasts for 4 hours to stop the reaction. After the device is completely cooled , 25.6 g carbon nanotubes were collected in the deposition chamber.

Embodiment 2

[0050] Pump the vacuum of the whole device to 5 Pa, turn off the vacuum pump, fill in 300 Torr argon gas from the hollow air intake path, turn on the power of the arc welding device, adjust the current to 200 A to trigger the arc, turn on the vacuum pump again, and enter the air from the hollow Add argon and methane to the gas circuit at a total flow rate of 750 sccm (flow rate ratio 2:1), adjust the exhaust valve of the system to maintain the vacuum degree of the arc chamber at 60000 Pa, and turn off the arc welding power supply to stop the reaction after the reaction lasts for 20 hours. After the device is completely cooled , 135 g carbon nanotubes were collected in the deposition chamber.

Embodiment 3

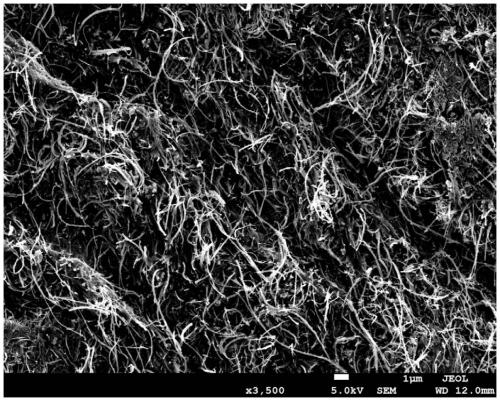

[0052] Pump the vacuum of the whole device to 5 Pa, turn off the vacuum pump, fill in 300 Torr argon gas from the hollow air intake path, turn on the power of the arc welding device, adjust the current to 200 A to trigger the arc, turn on the vacuum pump again, and enter the air from the hollow Add argon and methane to the gas path at a total flow rate of 750 sccm (flow rate ratio 2:1), adjust the exhaust valve of the system to maintain the vacuum degree of the arc chamber at 60000 Pa, and turn off the arc welding power supply after the reaction lasts for 40 hours to stop the reaction. After the device is completely cooled , 248 g carbon nanotubes were collected in the deposition chamber. The scanning morphology of the sample is as follows figure 2 As shown, the carbon nanotubes grown by the invented device have high purity and can reach tens of microns in length.

[0053] In embodiments 1 to 3, in the arc discharge vacuum furnace, the arc discharge method can adopt DC arc di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com