A kind of polyvinyl alcohol/modified nanocellulose supramolecular hydrogel and its preparation method and application

A technology of supramolecular hydrogel and nanocellulose, which is applied in the field of polyvinyl alcohol/modified nanocellulose supramolecular hydrogel and its preparation, can solve the problem of limited improvement of controlled release performance, failure to meet the needs of use, and low thermal expansion. Coefficient and other issues, to achieve good three-dimensional space structure, excellent water retention and adsorption performance, good release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

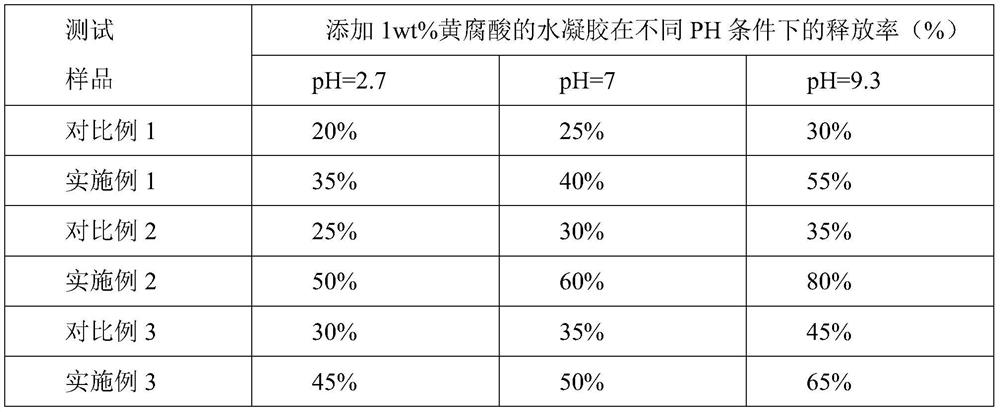

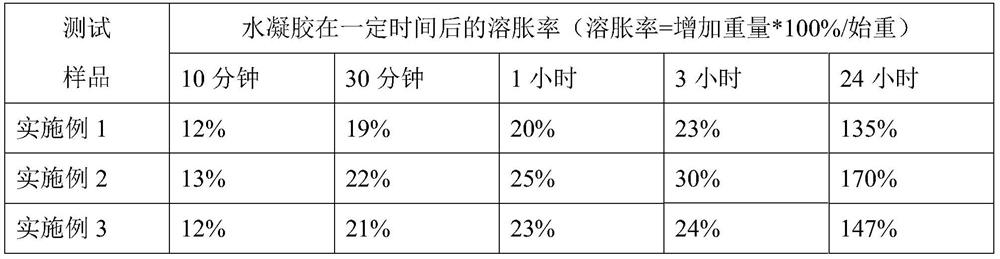

Embodiment 1

[0037] 1. Preparation of isocyanate-terminated 2-urea-4[H]-pyrimidinone:

[0038] Under nitrogen atmosphere, add 0.1mol 6-methylisocytosine and 1.5mol hexamethylene diisocyanate into 50ml of N,N-dimethylformamide, then react at 100°C for 16 hours, end the reaction, and lower the temperature to room temperature, the reactant was purified by n-pentane and placed in an oven for vacuum drying to obtain a white powder, which was the isocyanate-terminated 2-urea-4[H]-pyrimidinone, referred to as UPy-NCO;

[0039] 2. Preparation of polyvinyl alcohol / modified nanocellulose supramolecular hydrogel:

[0040] a) Add 20g of polyvinyl alcohol (abbreviation: PVA) into 100ml of water, stir at 100°C until completely dissolved, and prepare an aqueous solution of polyvinyl alcohol;

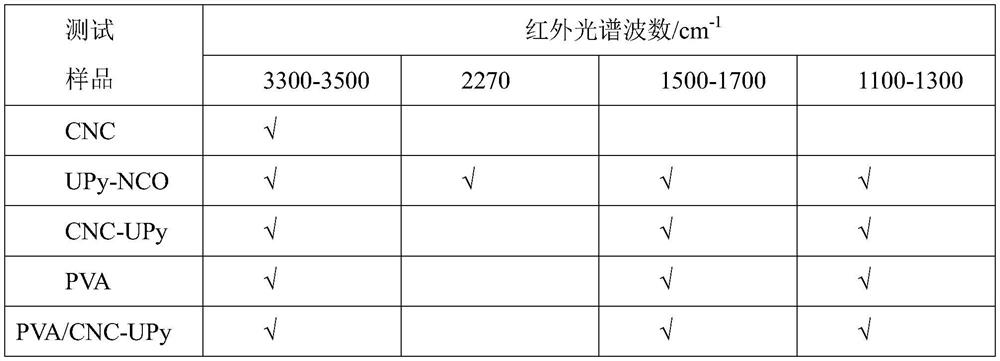

[0041] b) Add 1g of nanocellulose (abbreviation: CNC) and 6g of isocyanate-terminated 2-urea-4[H]-pyrimidinone to 50ml of rectification-grade DMF, add 0.1mL of dibutyltin dilaurate, at 100°C After reacting for 18 h...

Embodiment 2

[0050] 1. Preparation of isocyanate-terminated 2-urea-4[H]-pyrimidinone:

[0051] Under nitrogen atmosphere, add 0.1mol 6-methylisocytosine and 0.6mol hexamethylene diisocyanate into 50ml of N,N-dimethylformamide, then react at 110°C for 14 hours, end the reaction, and lower the temperature to room temperature, the reactant was purified by n-pentane and placed in an oven for vacuum drying to obtain a white powder, which was the isocyanate-terminated 2-urea-4[H]-pyrimidinone, referred to as UPy-NCO;

[0052] 2. Preparation of polyvinyl alcohol / modified nanocellulose supramolecular hydrogel:

[0053] a) Add 25g of polyvinyl alcohol into 100ml of water, stir at 100°C until completely dissolved, and prepare an aqueous solution of polyvinyl alcohol;

[0054] b) Add 2g of nanocellulose and 4g of isocyanate-terminated 2-urea-4[H]-pyrimidinone into 50ml of rectification-grade DMF, add 0.1ml of dibutyltin dilaurate, react at 110°C for 16 hours, and end reaction, the reactants were wa...

Embodiment 3

[0063] 1. Preparation of isocyanate-terminated 2-urea-4[H]-pyrimidinone:

[0064] Under a nitrogen atmosphere, add 1 mol of 6-methylisocytosine and 1.5 mol of hexamethylene diisocyanate into 50 ml of N,N-dimethylformamide, then react at 120°C for 12 hours, complete the reaction, and lower the temperature to At room temperature, the reactant was purified by n-pentane and dried in an oven under vacuum to obtain a white powder, which was the isocyanate-terminated 2-urea-4[H]-pyrimidinone, referred to as UPy-NCO;

[0065] 2. Preparation of polyvinyl alcohol / modified nanocellulose supramolecular hydrogel:

[0066] a) Add 30g of polyvinyl alcohol into 100ml of water, stir at 100°C until completely dissolved, and prepare an aqueous solution of polyvinyl alcohol;

[0067] b) Add 3g of nanocellulose and 3g of isocyanate-terminated 2-urea-4[H]-pyrimidinone into 50ml of rectification-grade DMF, add 0.1ml of dibutyltin dilaurate, and react at 120°C for 14 hours to end reaction, the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com