Preparation method of porous composite photo-thermal hydrogel based on polyvinyl alcohol and graphite powder

A technology of polyvinyl alcohol and graphite powder, which is applied in lighting and heating equipment, steam generation methods using solar energy, steam generation methods, etc., to achieve the effects of saving production costs, good mechanical properties, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the porous composite photothermal gel based on polyvinyl alcohol and graphite powder in this embodiment comprises the following steps:

[0032] Disperse 0.03g of graphite powder in 30mL of deionized water with vigorous stirring for 1h; add 3g of polyvinyl alcohol and stir vigorously at 80°C for 1.5h to completely dissolve; dissolve 1g of polyethylene glycol 20000 in 5mL of acetone, then add dropwise Among them, continue to stir to obtain a black viscous mixture; pour the mixture into a mold, put it in a -20°C refrigerator overnight, and perform freezing and cross-linking; take the sample out of the refrigerator and soak it in absolute ethanol for 12h, and then deionize Soak in water for 2 hours to obtain a composite hydrogel.

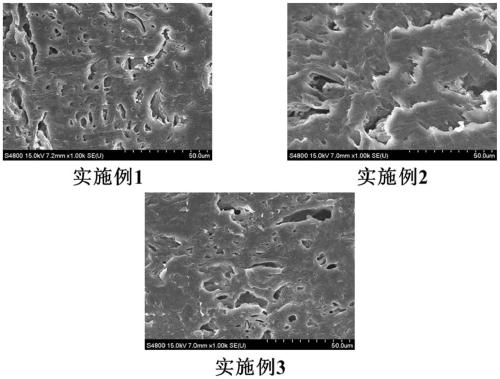

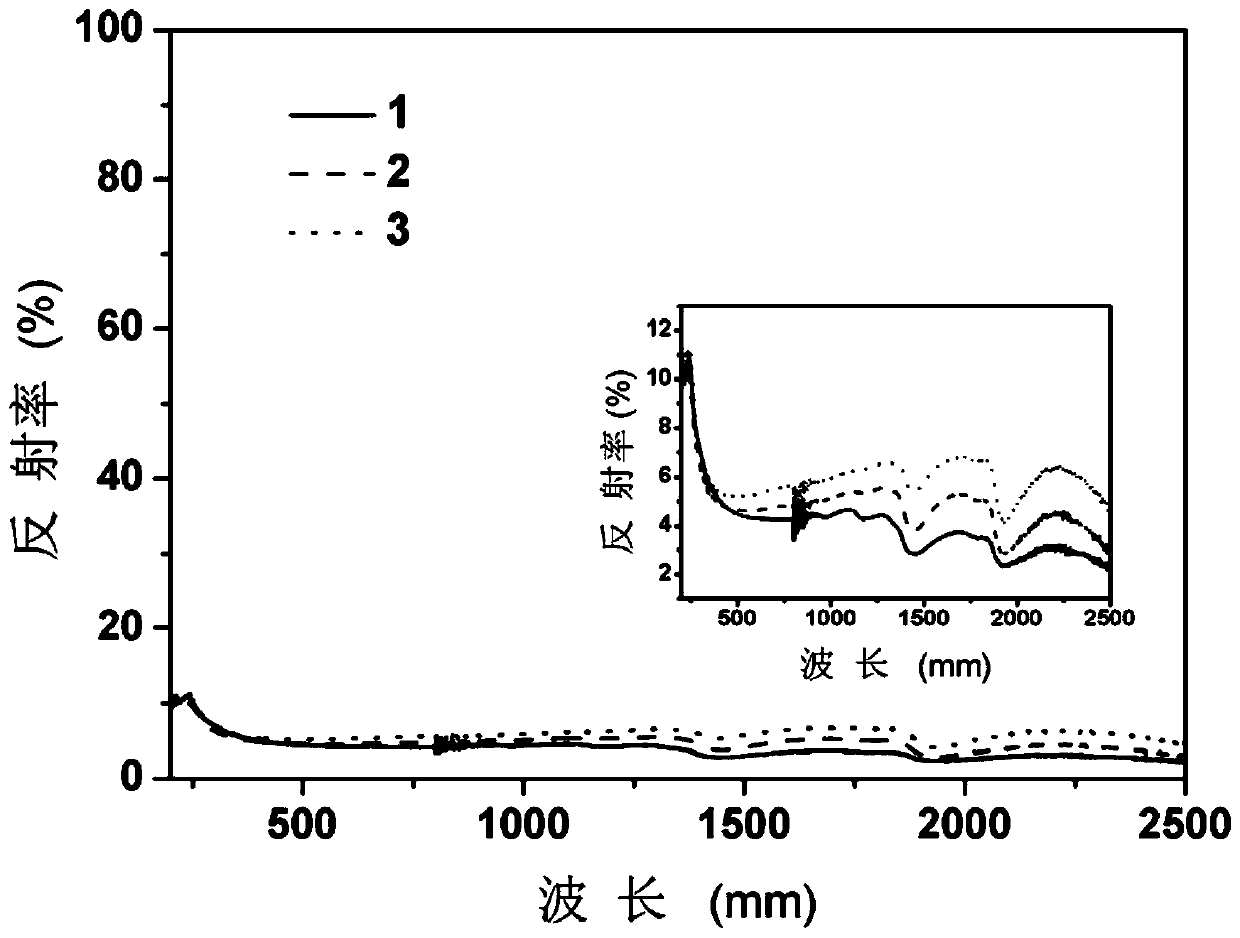

[0033] Measure the reflectance (i.e. optical properties) of the hydrogel with a UV-visible-near-infrared spectrophotometer, and the test range is 200-2500nm; after the hydrogel is freeze-dried, observe the morphology wit...

Embodiment 2

[0036] Disperse 0.09g of graphite powder in 30mL of deionized water with vigorous stirring for 1h; add 3g of polyvinyl alcohol and stir vigorously at 80°C for 2h to completely dissolve; dissolve 0.5g of polyethylene glycol 20000 in 10mL of acetone, then add dropwise Among them, continue to stir to obtain a black viscous mixture; pour the mixture into a mold, put it in a -20°C refrigerator overnight, and perform freezing and cross-linking; take the sample out of the refrigerator and soak it in absolute ethanol for 12h, and then deionize Soak in water for 2 hours to obtain a composite hydrogel.

[0037] Measure the reflectance (i.e. optical properties) of the hydrogel with a UV-visible-near-infrared spectrophotometer, and the test range is 200-2500nm; after the hydrogel is freeze-dried, observe the morphology with a scanning electron microscope; use a rheometer to measure the water The mechanical properties of the gel (including storage modulus and loss modulus); such as Figur...

Embodiment 3

[0039] Disperse 0.18g of graphite powder in 30mL of deionized water with vigorous stirring for 1h; add 3g of polyvinyl alcohol and stir vigorously at 85°C for 1.5h to achieve complete dissolution; dissolve 1g of polyethylene glycol 20000 in 10mL of acetone, then add dropwise Among them, continue to stir to obtain a black viscous mixture; pour the mixture into a mold, put it in a -20°C refrigerator overnight, and perform freezing and cross-linking; take the sample out of the refrigerator and soak it in absolute ethanol for 24h, and then deionize Soak in water for 2 hours to obtain a composite hydrogel.

[0040] Measure the reflectance (i.e. optical properties) of the hydrogel with a UV-visible-near-infrared spectrophotometer, and the test range is 200-2500nm; after the hydrogel is freeze-dried, observe the morphology with a scanning electron microscope; use a rheometer to measure the water The mechanical properties of the gel (including storage modulus and loss modulus); such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com