Quaternary ammonium salt modified Pd/C electrocatalyst as well as electrode and preparation and application thereof

An electrocatalyst and quaternary ammonium salt technology, applied in the field of electrochemistry, can solve the problems of weakening the mass transfer effect, affecting the dechlorination performance, etc., and achieve the effects of improving the dechlorination efficiency, high recycling rate and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

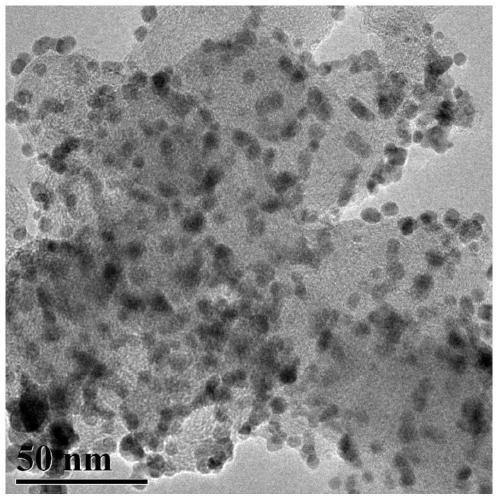

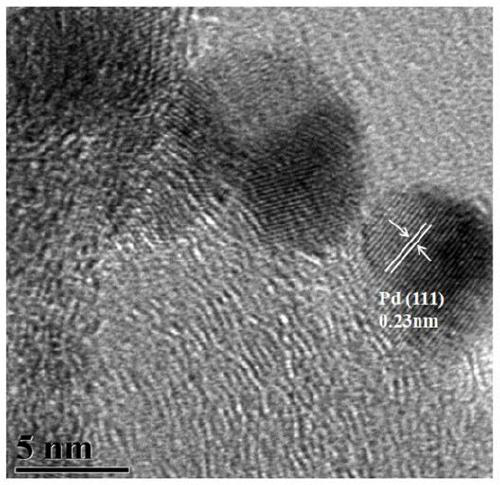

[0034] Embodiment 1: prepare the Pd / C electrocatalyst modified by quaternary ammonium salt

[0035] (1) Weigh 20mg of carbon powder, disperse it in 40mL deionized water, put it into an ultrasonic cleaner and ultrasonically evenly, and then transfer it to a constant temperature magnetic stirrer for stirring;

[0036] (2) After weighing 18 mg of sodium tetrachloropalladate and dissolving it in 10 mL of deionized water, slowly add it dropwise to the uniformly dispersed carbon powder solution of (1), and continue stirring;

[0037] (3) After stirring the mixture on a magnetic stirrer for 40 minutes, add NaBH dropwise 4 Solution, keep stirring for reaction, suction filter after the reaction, wash with deionized water several times, put it into a constant temperature oven and dry to obtain nano Pd / C composite material;

[0038] (4) The tetraethylammonium chloride that takes 0.3637g is dissolved in the ethanol of 50mL;

[0039] (5) Weigh 15 mg of nano-Pd / C composite material and di...

Embodiment 2

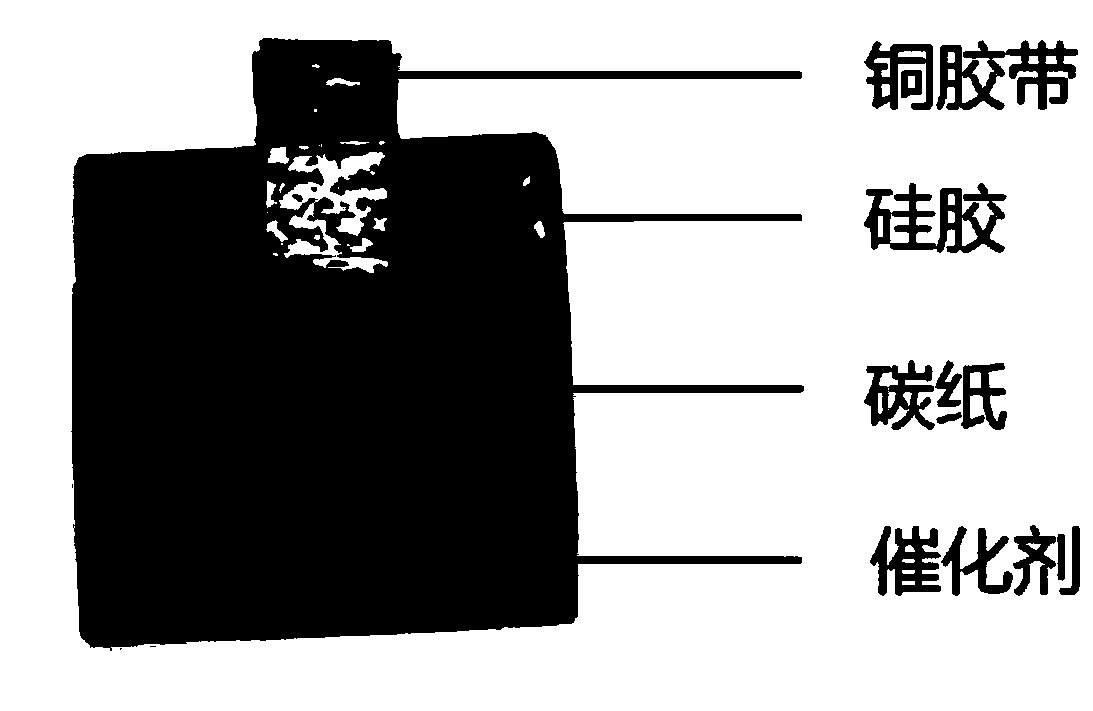

[0041] Embodiment 2: prepare the Pd / C electrocatalyst electrode of quaternary ammonium salt modification

[0042] (1) Cut 3*3cm 2 Then cut out 2cm of copper glue, fold it in half, paste it on both sides of the carbon paper, and leave a length of 0.5cm, and apply silica gel on the carbon paper area with copper glue, with a thickness of 1mm;

[0043] (2) In the Pd / C electrocatalyst modified by the quaternary ammonium salt prepared in Example 1, add 40uL Nafion, 0.4mL isopropanol as a binder, and ultrasonically disperse the mixed solution; pipette the mixed solution with a dropper, Evenly drip onto the blank carbon paper (that is, the area without copper glue and silica gel). When dripping, you need to wait for the last applied liquid to evaporate completely before dripping it again; after dripping, put it in a constant temperature oven and bake it. The Pd / C electrocatalyst electrode modified by quaternary ammonium salt can be obtained.

[0044] The real photo of the Pd / C elect...

Embodiment 3

[0045] Example 3: Use the Pd / C electrocatalyst electrode modified by the quaternary ammonium salt prepared in Example 2 to investigate its dechlorination effect on the pollutant 2,4-dichlorophenol

[0046](1) The construction of the dechlorination reaction device, the steps are as follows:

[0047] a) The dechlorination reaction tank is an H-type electrolyzer; the anode chamber is separated from the cathode chamber by a cation exchange membrane (Nafion-117), and the volume of the two chambers is 200mL; sodium sulfate is added to the anode chamber and the cathode chamber as Electrolyte, the volume is 100mL, and nitrogen gas must be flowed for 10min before the reaction; B-type magnetic stirring bar stirring;

[0048] b) According to the principle of the three-electrode system, build the circuit of the electrocatalytic dechlorination device, wherein the counter electrode is a platinum electrode (30mm×30mm), the reference electrode is Ag / AgCl (3.0M KCl), and the working electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com