Complete pellet feed for improving production performance of Shanbei white cashmere goat, preparation method and application thereof

A technology of pellet feed and production performance, applied in application, animal feed, animal feed, etc., can solve the problems affecting the health and production performance of northern Shaanxi white cashmere goats, the shortage of forage, nutritional cost, and unreasonable matching, so as to solve the problems of forage Effects of shortage, improved rumen health, and faster cashmere production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh the following raw materials by weight: 40 parts of corn, 6 parts of sprayed corn husks, 5 parts of wheat bran, 8.2 parts of alfalfa powder, 10 parts of soybean meal, 7 parts of cotton meal, 10 parts of soybean hulls, 5 parts of apple pomace, sunflower 5 parts of shell, 0.3 part of ruminant yeast, 0.05 part of guanidinoacetic acid, 1 part of stone powder, 0.5 part of sodium bicarbonate, 0.6 part of sodium chloride, 0.3 part of sodium sulfate, 0.1 part of coated methionine, 0.45 part of lysine, anti-mold 0.03 part of sweetener, 0.02 part of sweetener, 0.03 part of xylooligosaccharide, 0.02 part of compound enzyme preparation, 0.2 part of trace element additive, and 0.2 part of multivitamin.

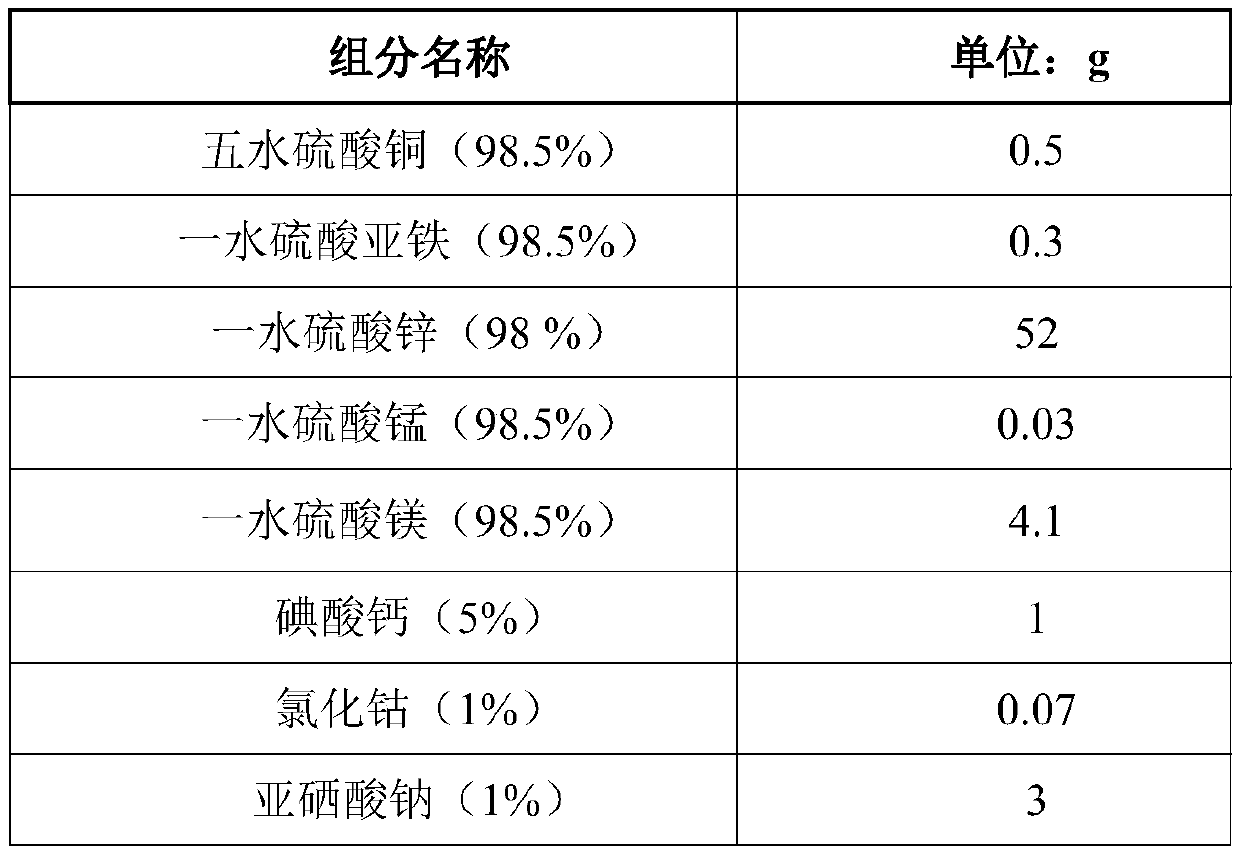

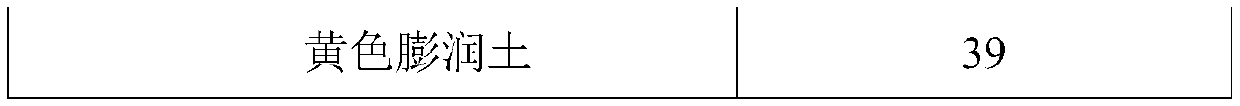

[0032] Among them, the trace element additive is composed of the composition in Table 1, and the multivitamin is composed of the composition in Table 2.

[0033] Table 1 Trace element additive formula table

[0034]

[0035]

[0036] Table 2 Compound vitamin formula tabl...

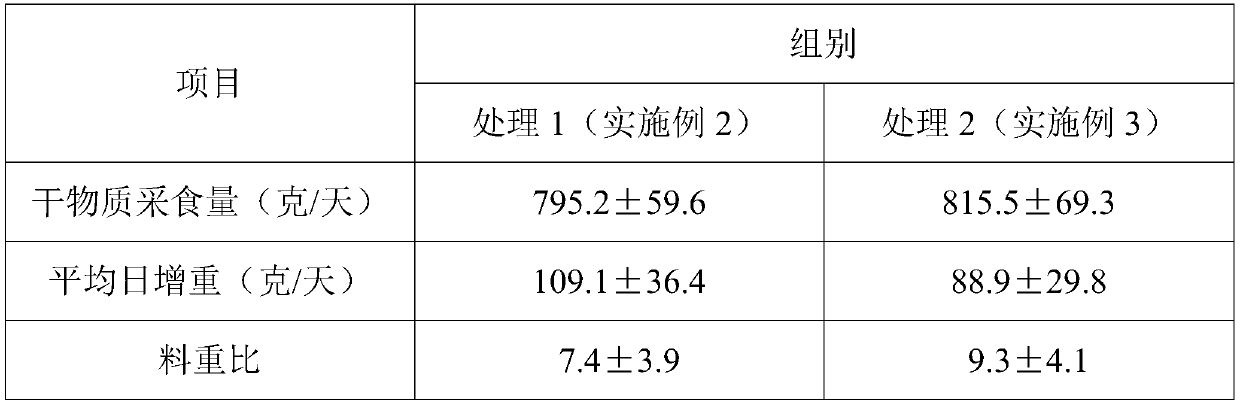

Embodiment 2

[0040] Weigh the following raw materials by weight: 43 parts of corn, 6 parts of sprayed corn husks, 5 parts of wheat bran, 6.5 parts of alfalfa powder, 10 parts of soybean meal, 6 parts of cotton meal, 10 parts of soybean hulls, 5.9 parts of apple pomace, sunflower 5 parts of shell, 0.1 part of ruminant yeast, 0.05 part of guanidinoacetic acid, 0.33 part of stone powder, 0.4 part of sodium bicarbonate, 0.4 part of sodium chloride, 0.4 part of sodium sulfate, 0.1 part of coated methionine, 0.3 part of lysine, anti-mold 0.03 parts of sweeteners, 0.02 parts of sweeteners, 0.05 parts of xylooligosaccharides, 0.02 parts of compound enzyme preparations, 0.2 parts of trace element additives, and 0.2 parts of multivitamins.

[0041] Wherein the trace element additive is composed of the Table 1 distribution in Example 1, and the multivitamin is composed of the Table 2 distribution in Example 1.

[0042] Preparation method: crush corn, and sieve with a double-layer primary cleaning sie...

Embodiment 3

[0044] Weigh the following raw materials by weight: 43 parts of corn, 6 parts of sprayed corn husks, 5 parts of wheat bran, 6.5 parts of alfalfa powder, 10 parts of soybean meal, 6 parts of cotton meal, 10 parts of soybean hulls, 5.9 parts of apple pomace, sunflower 5 parts of shell, 0.1 part of ruminant yeast, 0.08 part of guanidinoacetic acid, 0.45 part of stone powder, 0.4 part of sodium bicarbonate, 0.4 part of sodium chloride, 0.4 part of sodium sulfate, 0.3 part of lysine, 0.03 part of antifungal agent, sweet taste 0.02 parts of agent, 0.02 parts of compound enzyme preparation, 0.2 part of trace element additive, and 0.2 part of multivitamin.

[0045]Wherein the trace element additive is composed of the Table 1 distribution in Example 1, and the multivitamin is composed of the Table 2 distribution in Example 1.

[0046] Compared with Example 2, Example 3 cancels the coating amino acid and xylooligosaccharide.

[0047] Preparation method: crush corn, and sieve with a dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com