Natural plant manual cold-made soap and preparation method thereof

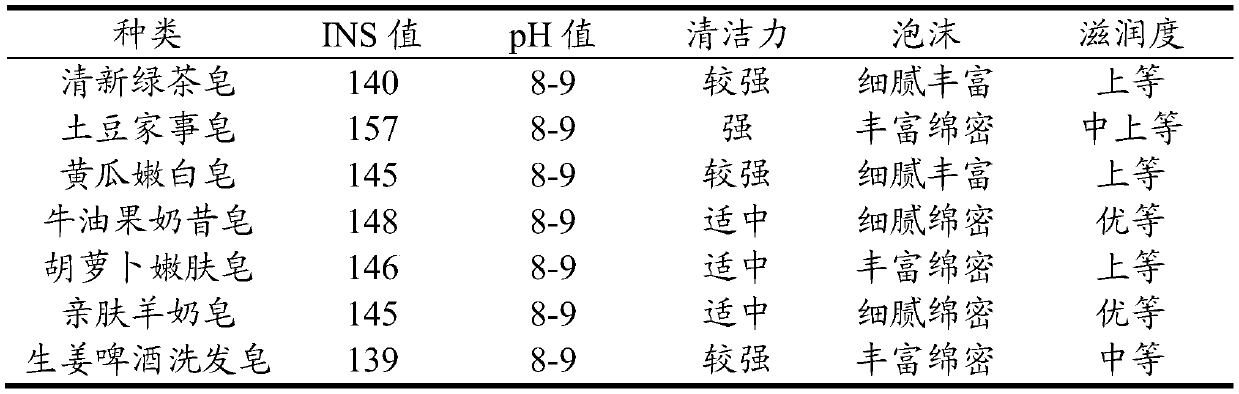

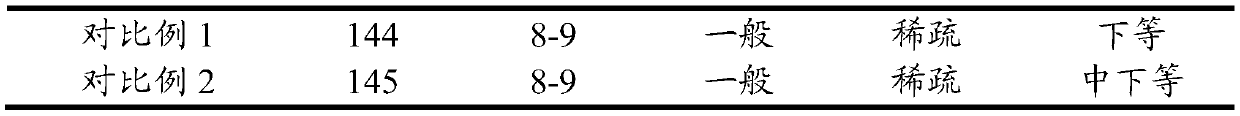

A technology of natural plants and natural vegetable oils, applied in the field of natural plant handmade cold-process soap and its preparation, can solve the problems of general cleaning power and less foam, and achieve the effects of rich foam, natural ingredients and improved cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a kind of natural vegetable manual cold process soap, including natural oil 192g, water phase substance 85g, sodium hydroxide 29g;

[0034] Wherein the natural oil is formed by mixing 50g of olive oil, 50g of coconut oil, 40g of shea butter, 20g of grapeseed oil, 20g of rice bran oil and 12g of nut oil; wherein the water phase material is milk and green tea.

[0035] Present embodiment also provides the preparation method of this manual cold process soap, comprises the following steps:

[0036] S1, take by weighing 50g olive oil, 50g coconut oil, 40g shea butter, 20g grapeseed oil, 20g rice bran oil and 12g nut oil and mix to obtain natural oil;

[0037] Freeze milk at -20°C into milk ice cubes, weigh 80g of milk ice cubes, soak 5g of green tea in 20mL of boiling water for 20min, filter to obtain filtrate, mix milk ice cubes with 5mL of green tea filtrate, and set aside;

[0038] Take by weighing sodium hydroxide 29g, set aside;

[0039...

Embodiment 2

[0044] This embodiment provides a kind of natural plant handmade cold process soap, including natural oil 200g, water phase substance 76g, sodium hydroxide 30g;

[0045] Wherein the natural oil is formed by mixing 72g coconut oil, 56g palm oil, 12g white oil and 60g canola oil; wherein the water phase substance is potato clear juice.

[0046] Present embodiment also provides the preparation method of this manual cold process soap, comprises the following steps:

[0047] S1, take by weighing 72g coconut oil, 56g palm oil, 12g white oil and 60g canola oil and mix to obtain natural oil, for subsequent use;

[0048] After washing and peeling the potatoes, crush them, and filter to obtain clear potato juice, weigh 76g of potato clear juice, and set aside;

[0049] Take by weighing sodium hydroxide 30g, set aside;

[0050] S2. Mix the potato clear juice weighed in S1 with the sodium hydroxide weighed in S1, and stir at 36° C. to completely dissolve the sodium hydroxide to obtain a...

Embodiment 3

[0055] This embodiment provides a kind of natural plant handmade cold process soap, including natural oil 200g, water phase substance 74g, sodium hydroxide 29g;

[0056] Wherein the natural oil is formed by mixing 54g olive oil, 40g coconut oil, 50g palm oil, 10g white oil and 46g sweet almond oil; wherein the water phase substance is cucumber juice.

[0057] Present embodiment also provides the preparation method of this manual cold process soap, comprises the following steps:

[0058] S1, take by weighing 54g olive oil, 40g coconut oil, 50g palm oil, 10g white oil and 46g sweet almond oil and mix to obtain natural oil, set aside;

[0059] Cucumber is crushed, and filtered to obtain cucumber juice, take 74g of cucumber juice, set aside;

[0060] Take by weighing sodium hydroxide 29g, set aside;

[0061] S2. Mix the cucumber juice weighed in S1 with the sodium hydroxide weighed in S1, and stir at 32° C. to completely dissolve the sodium hydroxide to obtain an aqueous phase mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com