A method for growing perovskite single crystal by layer solution method

A perovskite, solution method technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low success rate of single crystal growth, harsh experimental environment requirements, complicated operation process, etc., and achieve crystal nucleation. The effect of stable growth process, low experimental environment requirements and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

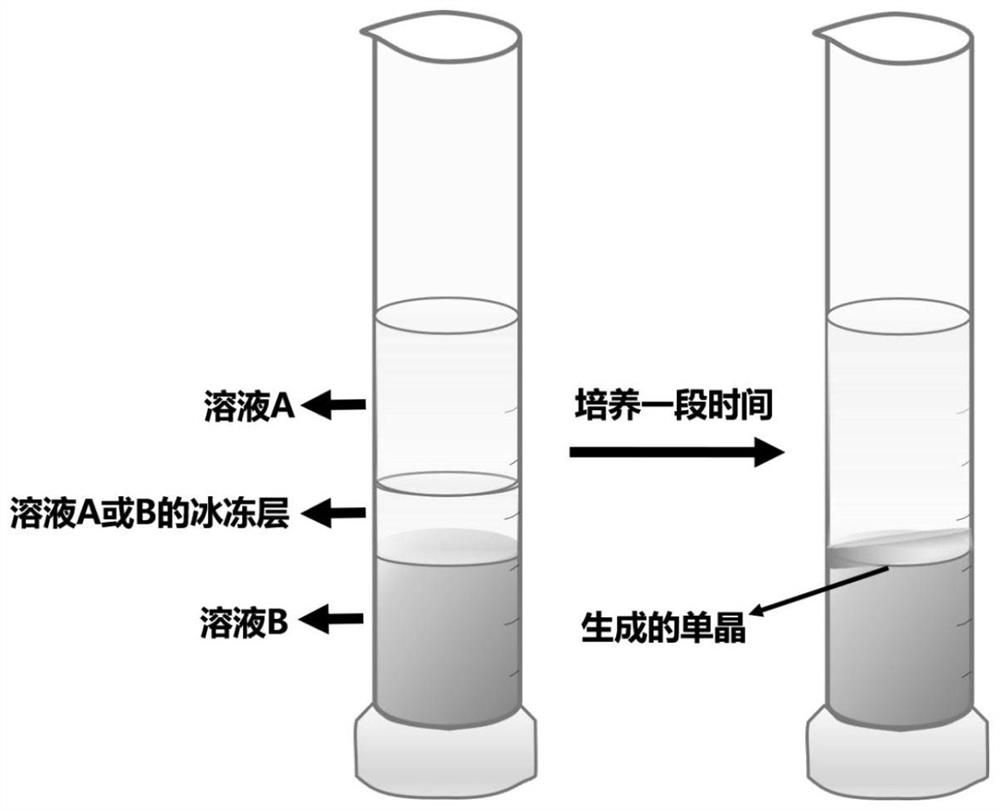

Method used

Image

Examples

Embodiment 1

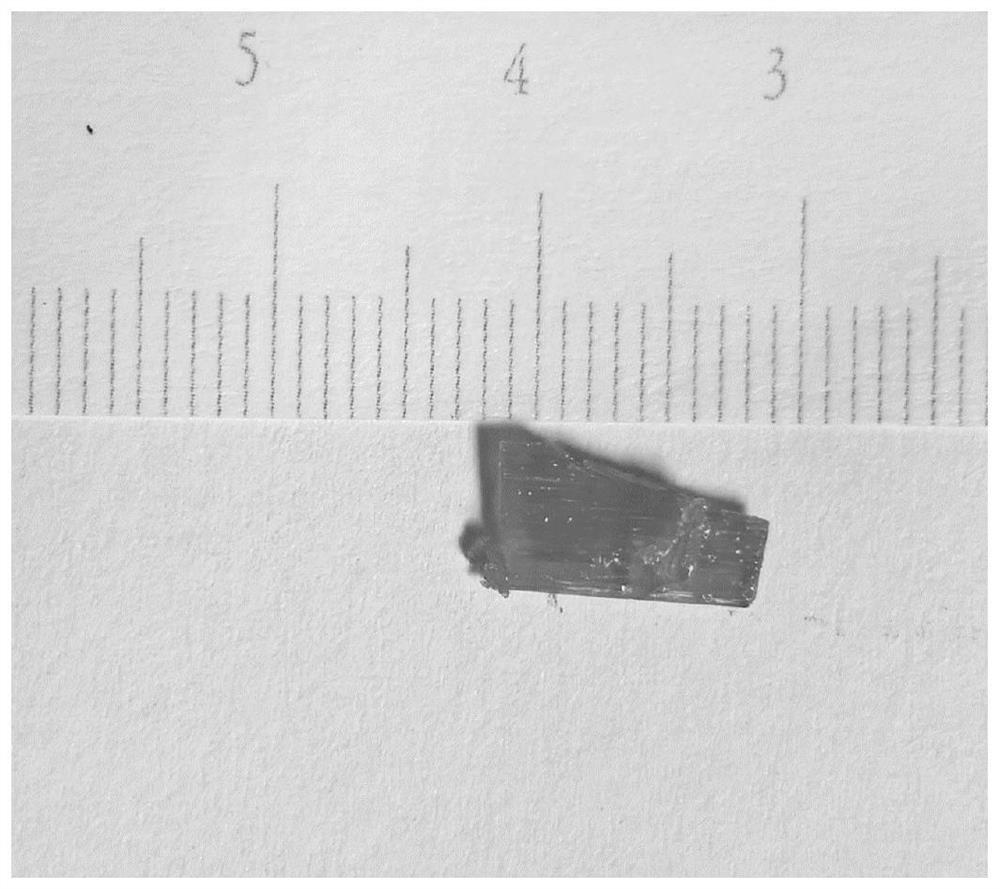

[0037] Add 3 cm of solution B (BiI 3 HI solution, 1mol / L), 1cm of solution B frozen layer (temperature is -20 ℃), 3cm of solution A (PhAI (benzyl ammonium iodide) ethanol solution, 1mol / L), where solution A , The titration rate of B was 1mL / min, and the perovskite single crystal PhABiI was obtained after static culture at 25°C for 10 days 3 , the physical picture of the obtained perovskite single crystal is shown in figure 2 shown.

[0038] Depend on figure 2 It can be seen that the size of the perovskite single crystal obtained by the method of the present invention is 1.1 cm, and the crystallinity is good, and the crystal quality is high.

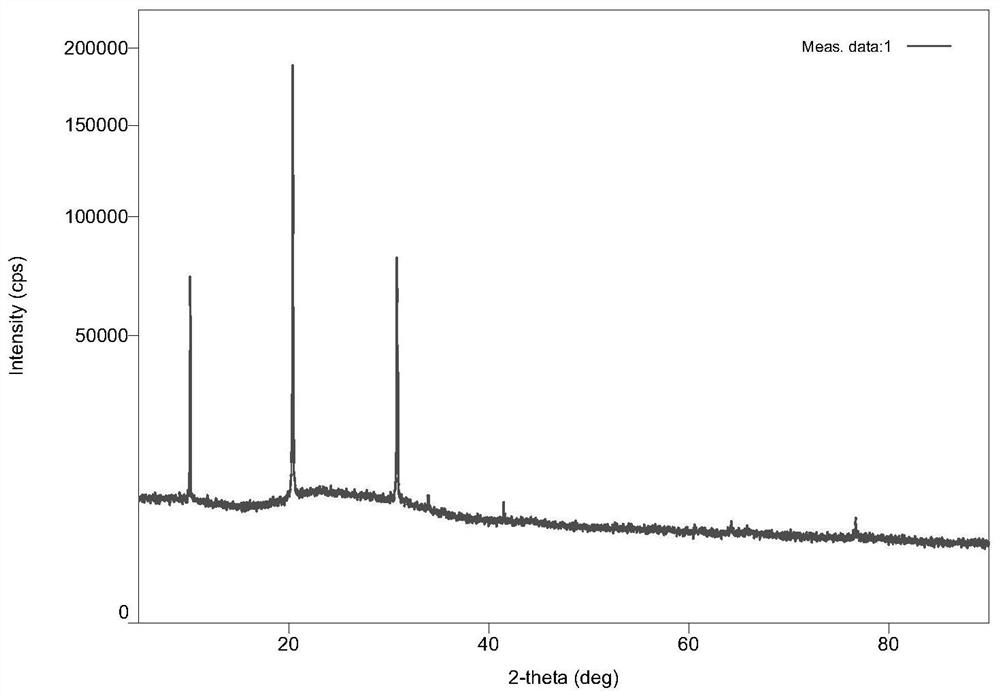

[0039] Carry out X-ray diffraction to the obtained perovskite single crystal, the obtained result is as follows image 3 shown. Depend on image 3 It can be seen that there are only three obvious characteristic peaks in the XRD diffraction pattern, and the distribution of the three peaks has certain rules, which are obviously the ...

Embodiment 2

[0041] Add 2 cm of solution B (C 4 h 12 DMF solution of BrN (tetramethylammonium bromide), 1mol / L), 0.5cm of frozen layer of solution B (at a temperature of 10°C), 4cm of solution A (CuBr 2 (copper bromide) hydrobromic acid solution, 1mol / L), wherein the rate of instillation of solutions A and B is 0.2mL / min, after standing and culturing for 30 days under the condition of -20°C, a perovskite single crystal is obtained [ C 4 h 12 N] 2 CuBr 4 .

Embodiment 3

[0043] Add 2 cm of solution B (C 4 h 12 DMF solution of IN (tetramethylammonium iodide), 1mol / L), 0.1cm of frozen layer of solution B (temperature is 0°C), 1cm of solution A (CuI 2 (the DMF solution of copper iodide, 1mol / L), wherein the rate of addition of solution A, B is 2mL / min, obtain perovskite single crystal [C 4 h 12 N] 2 CuI 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com