Inkjet printing method by using coating-type ink with organic-inorganic coated pigment color paste

A pigment paste, inorganic coating technology, applied in the direction of pigment paste, dyeing method, application, etc., can solve the problems of poor affinity between pigment and fabric, poor fabric feel, poor color fastness, etc., to reduce seepage phenomenon, improve color yield, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

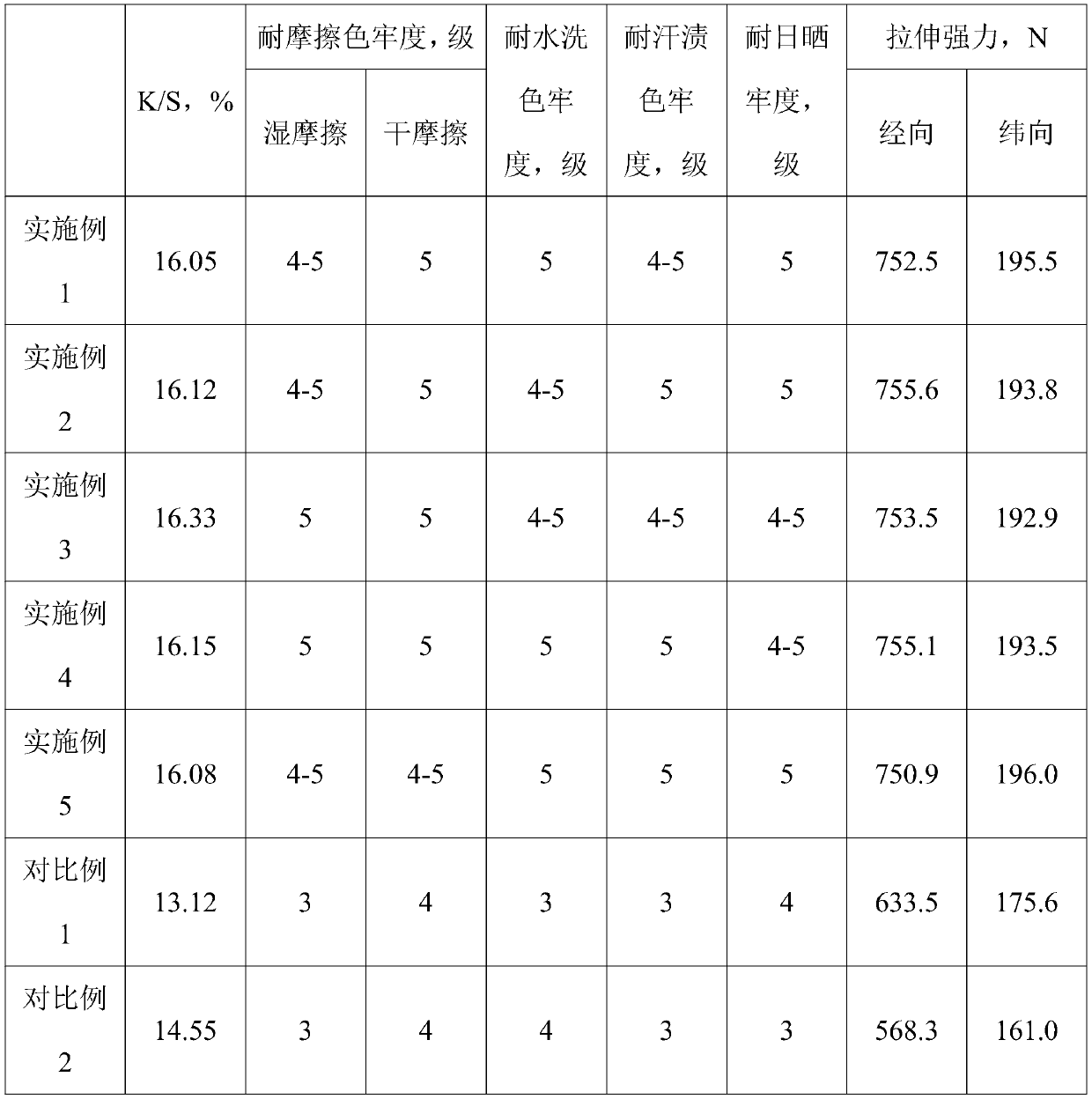

Examples

Embodiment 1

[0036] A method of ink-jet printing using a paint-based ink comprising an organic-inorganic coated pigment paste, comprising the following steps:

[0037] (1) Add 1g of magenta pigment particles and 0.013gspan80 to deionized water to prepare a mixed solution and transfer it to a ball mill tank, control the material-liquid ratio to 1:1, set the speed at 580rpm, and ball mill for 7 hours to obtain a pigment dispersion Stir 5g of gelatin and deionized water at 40-50°C until the solid dissolves to obtain a gelatin solution, add the pigment dispersion liquid dropwise to the gelatin solution, continue to stir and mix at 40-50°C for 1 hour, and then add 1g of the mass A sodium citrate solution with a concentration of 5% was used to adjust the pH to 3.5-4, and cooled to room temperature to obtain a mixed emulsion; the mixed emulsion was mixed with 1.88 g of a glutaraldehyde solution with a mass concentration of 8% and stirred at 10°C for 1 hour. After filtering, the microcapsule pigme...

Embodiment 2

[0044] A method of ink-jet printing using a paint-based ink comprising an organic-inorganic coated pigment paste, comprising the following steps:

[0045] (1) Add 1g of magenta pigment particles and 0.013gspan80 to deionized water to prepare a mixed solution and transfer it to a ball mill tank, control the material-liquid ratio to 1:1, set the speed at 580rpm, and ball mill for 7 hours to obtain a pigment dispersion Stir 10g of gelatin and deionized water at 40-50°C until the solid dissolves to obtain a gelatin solution, add dropwise pigment dispersion to the gelatin solution, continue stirring and mixing at 40-50°C for 1 hour, then add 1g of the mass A sodium citrate solution with a concentration of 5% was used to adjust the pH to 3.5-4, and cooled to room temperature to obtain a mixed emulsion; the mixed emulsion was mixed with 2.5 g of a glutaraldehyde solution with a mass concentration of 8% and stirred at 10° C. for 1 hour. After filtering, the microcapsule pigment is obt...

Embodiment 3

[0052] A method of ink-jet printing using a paint-based ink comprising an organic-inorganic coated pigment paste, comprising the following steps:

[0053] (1) Add 1 g of cyan pigment particles and 0.013 gspan80 to deionized water to prepare a mixed solution and transfer it to a ball mill tank, control the material-liquid ratio to 1:1, set the rotation speed to 580 rpm, and ball mill for 7 hours to obtain a pigment dispersion; Stir 6g of gelatin and deionized water at 40-50°C until the solid dissolves to prepare a gelatin solution, add dropwise pigment dispersion to the gelatin solution, continue stirring and mixing at 40-50°C for 1 hour, then add dropwise 1g of mass concentration Adjust the pH to 3.5-4 for the 5% sodium citrate solution, cool to room temperature to prepare a mixed emulsion; mix the mixed emulsion with 1.9 g of a glutaraldehyde solution with a mass concentration of 8% and stir at 10°C for 1 hour, then Filtration to obtain microcapsule pigments;

[0054] (2) Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com