Ultrasonic-assisted electrochemical mechanical polishing processing device and method for SiC single crystal wafer

An ultrasonic-assisted, mechanical polishing technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problem of low material removal rate, and achieve the effect of high removal efficiency, easy processing method and simple processing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

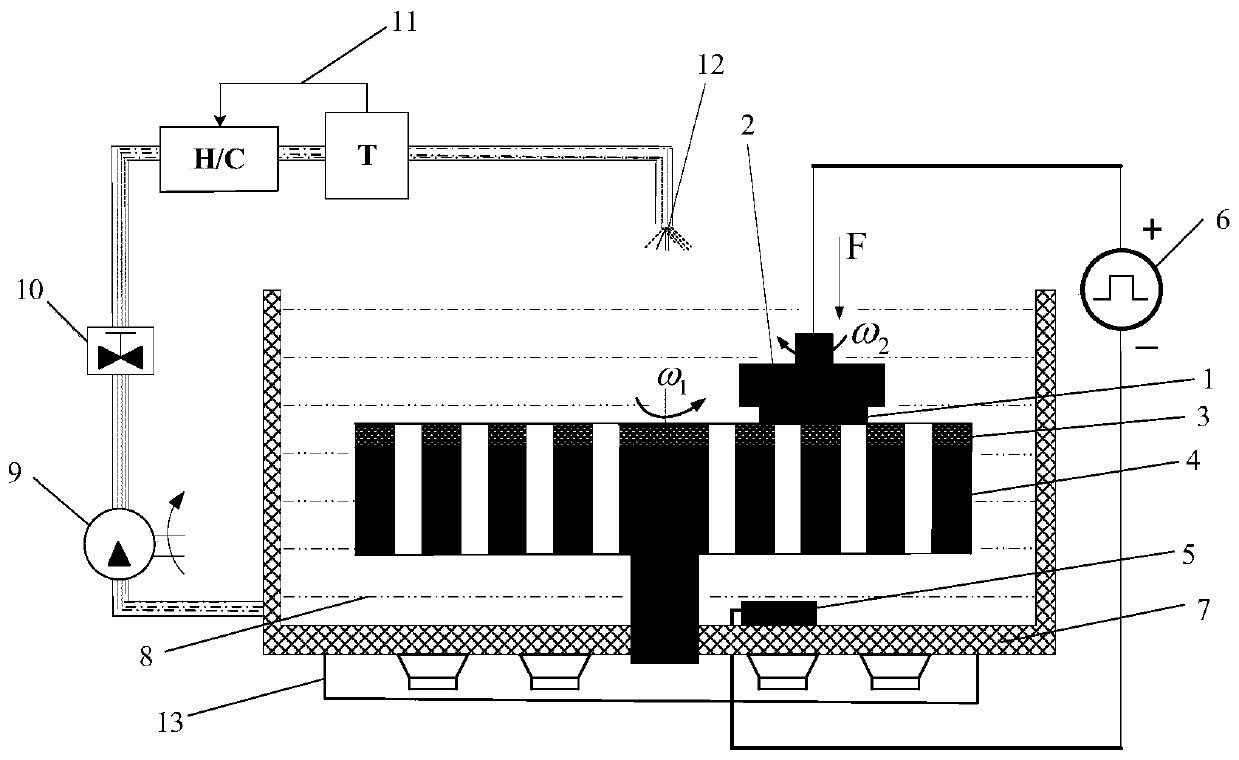

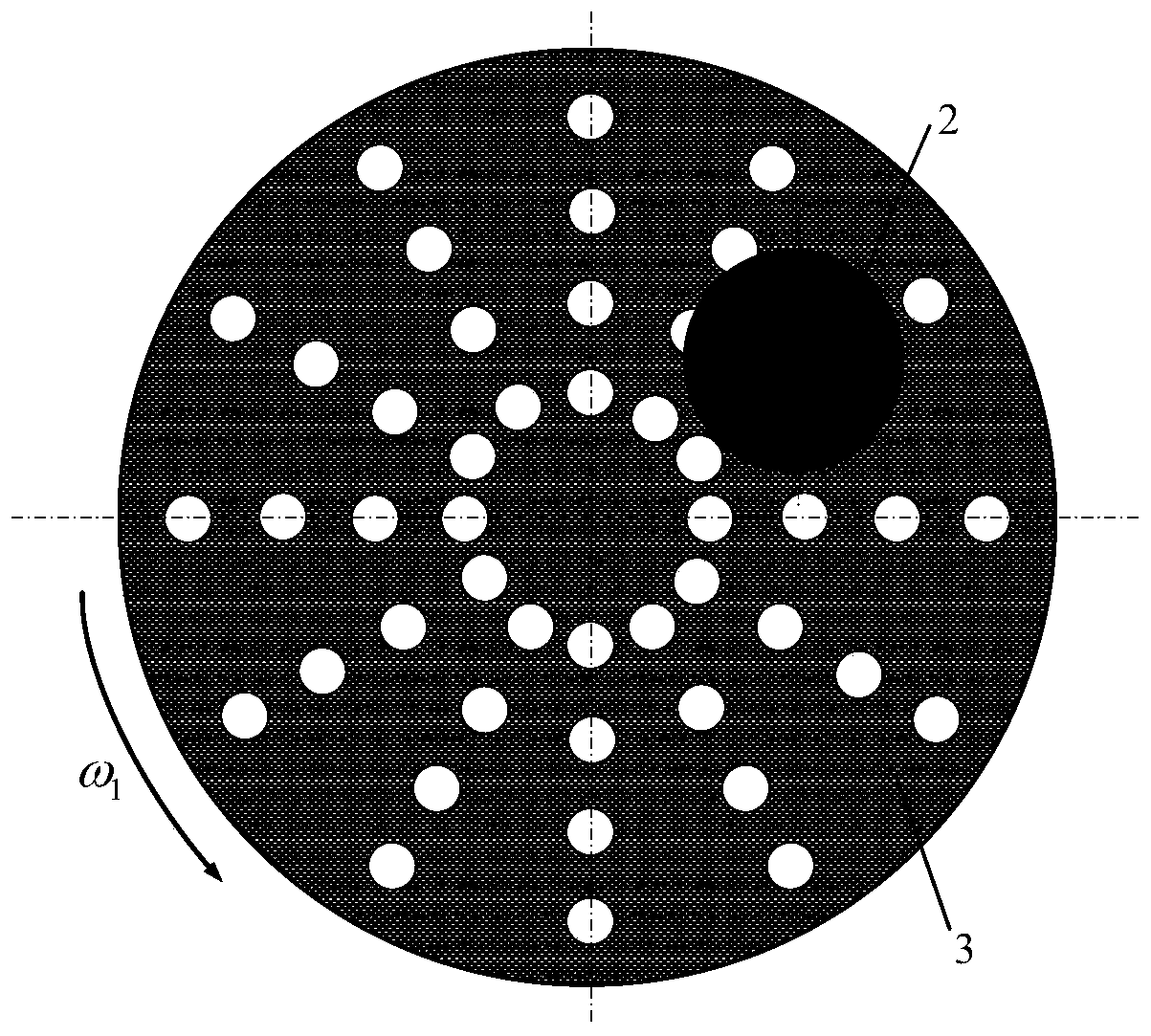

[0030] An ultrasonic-assisted electrochemical mechanical polishing device for a SiC single wafer, such as figure 1 Shown, comprise glass tank 7, the bottom outer surface of glass tank 7 is provided with ultrasonic device 13, glass tank 7 inside is full of polishing liquid 8, is provided with the polishing disc 4 that can rotate along central axis in the polishing liquid 8, on the polishing disc 4 A polishing pad 3 is arranged on the surface, and a carrier plate 2 that can rotate along the central axis is connected to the top of the SiC single wafer 1 through conductive glue, and the rotation direction of the polishing plate 4 and the carrier plate 2 is opposite; The surface is provided with a stainless steel electrode 5, the stainless steel electrode 5 is connected to the negative pole of the pulse power supply 6, the positive pole of the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com