Preparation method of carbon-based flexible lithium-sulfur battery cathode material of porous structure

A carbon-based flexible lithium-sulfur battery technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of lithium polysulfide intermediates easily soluble in electrolyte, sulfur active materials with poor conductivity, and inability to bend and fold, etc., to achieve Effects of slowing down the speed of dissolution and diffusion, increasing loading capacity, good operability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: This implementation mode records a method for preparing a porous structure carbon-based flexible lithium-sulfur battery positive electrode material. The specific steps of the method are as follows:

[0023] Step 1: use the three-dimensional carbon-based conductive fiber network as a current collector, and immerse it in a solution containing a sulfur active substance; or first immerse the three-dimensional carbon-based conductive fiber network as a current collector in a solvent, and then mix it with a solution containing a sulfur active substance; The concentration of the solution containing the sulfur active substance is 0.05-1.5 g / mL, and the ambient temperature of this step is 5-45°C;

[0024] Step 2: Under a closed vacuum or high pressure condition, the solution containing the sulfur active substance is infiltrated into the pore structure of the three-dimensional carbon-based conductive fiber network by shaking, and the same pressure c...

specific Embodiment approach 2

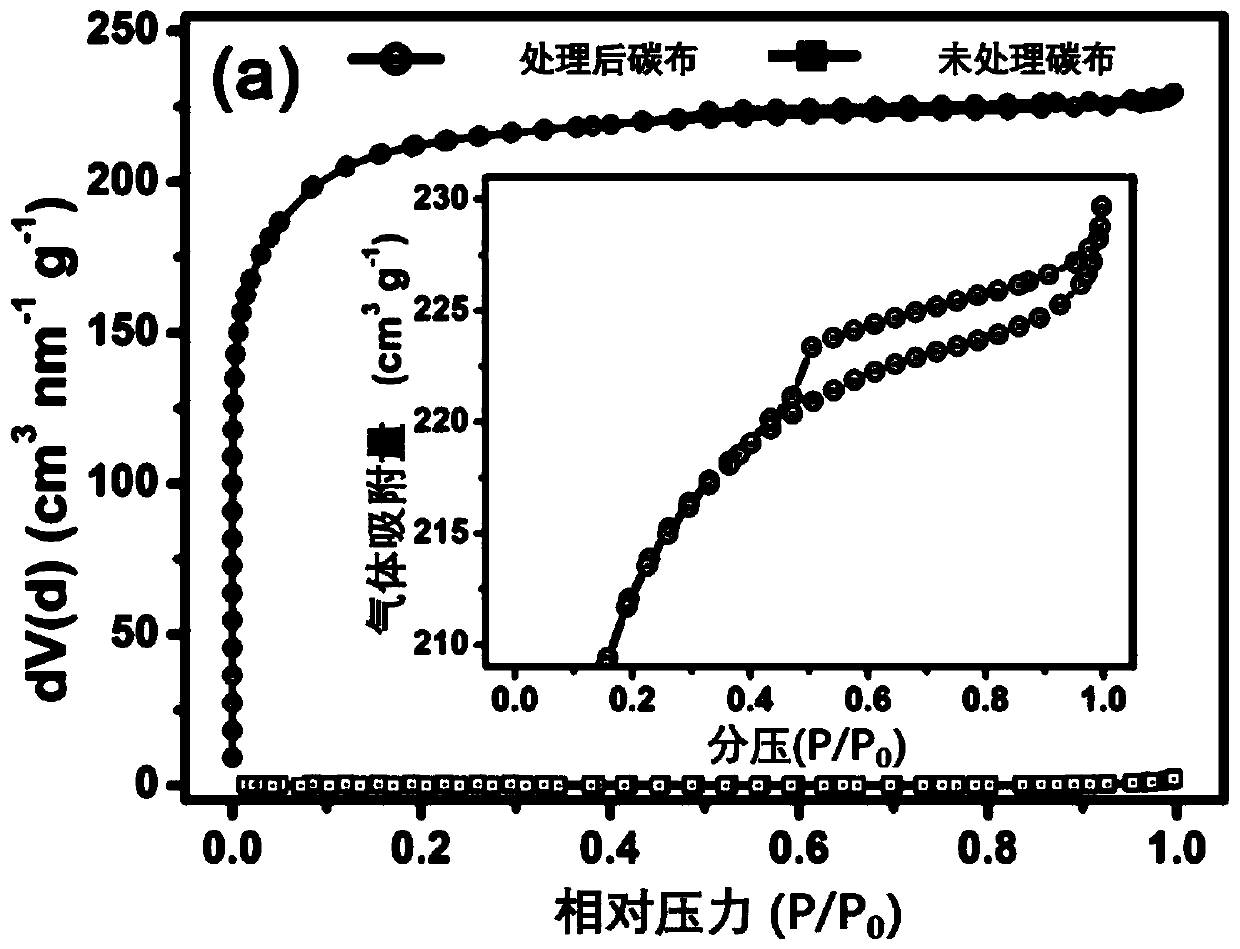

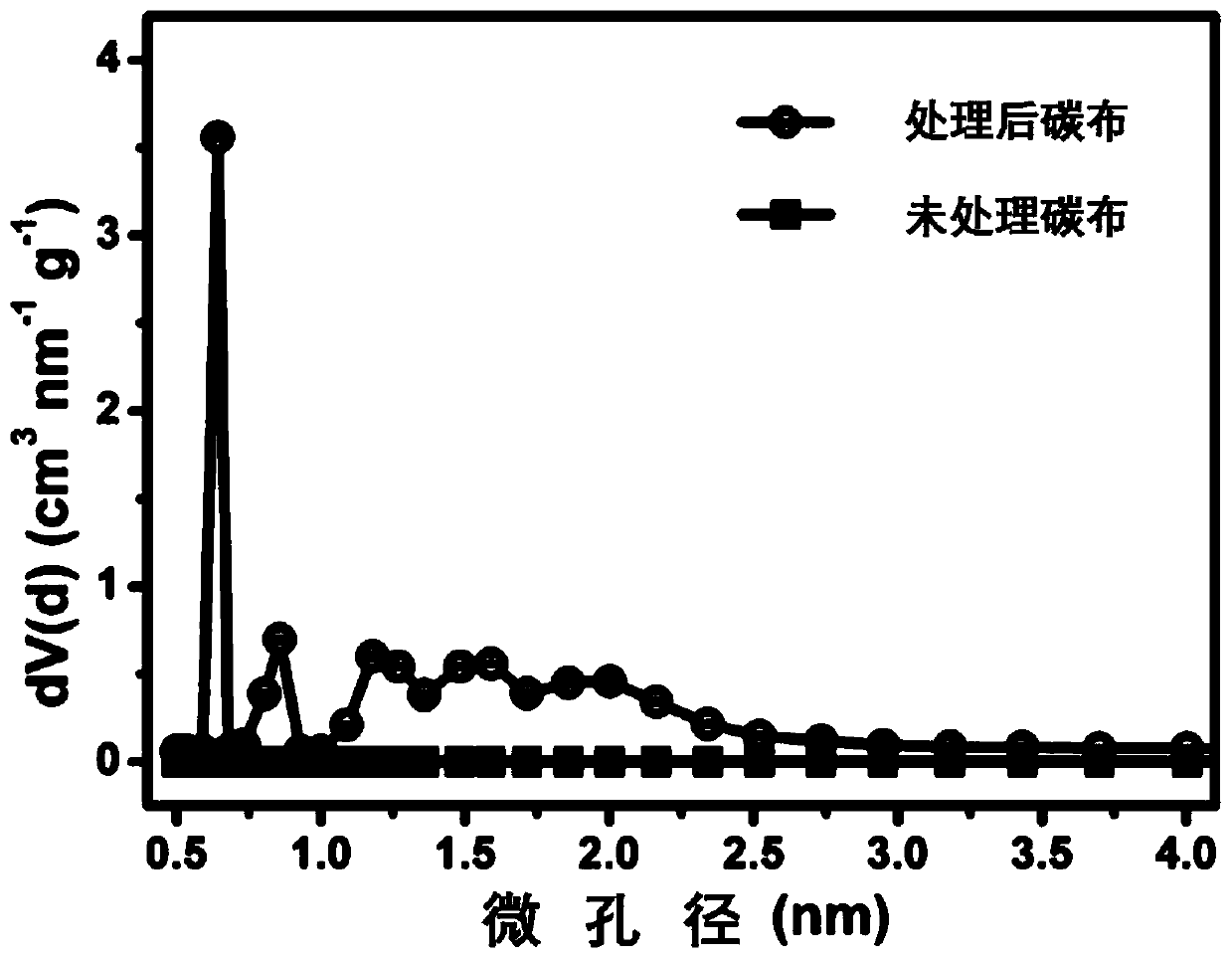

[0026] Specific embodiment 2: The preparation method of a porous carbon-based flexible lithium-sulfur battery positive electrode material described in specific embodiment 1, the described three-dimensional carbon-based conductive fiber network has a rich pore structure such as figure 1 , 2 As shown in the BET test results, including micropores, mesopores and macropores, the pore structure is mainly distributed in the range of micropores and mesopores from 0.5 to 3.5 nm.

specific Embodiment approach 3

[0027] Embodiment 3: The preparation method of a porous structure carbon-based flexible lithium-sulfur battery positive electrode material described in Embodiment 1. In step 1, the three-dimensional carbon-based conductive fiber network is prepared according to the following method:

[0028] Using carbon fibers or materials that can form highly conductive carbon-based fibers after carbonization as raw materials, treat them in an atmosphere with an oxidation volume concentration of 1% to 80% at 250-610°C to partially oxidize the carbon materials to obtain a ratio with a certain strength. A three-dimensional carbon-based conductive fiber network with controllable surface area, high conductivity and flexibility; the treatment temperature is 250-610° C., and the oxygen volume concentration is 1%-80%.

[0029] The three-dimensional carbon-based conductive fiber network can be a carbon-based fiber with certain conductivity and strength made of natural cellulose fibers such as bamboo,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com