Single cell protein from thermophilic fungi

A thermophilic fungus, protein technology, applied in the field of microbiology and fermentation, can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

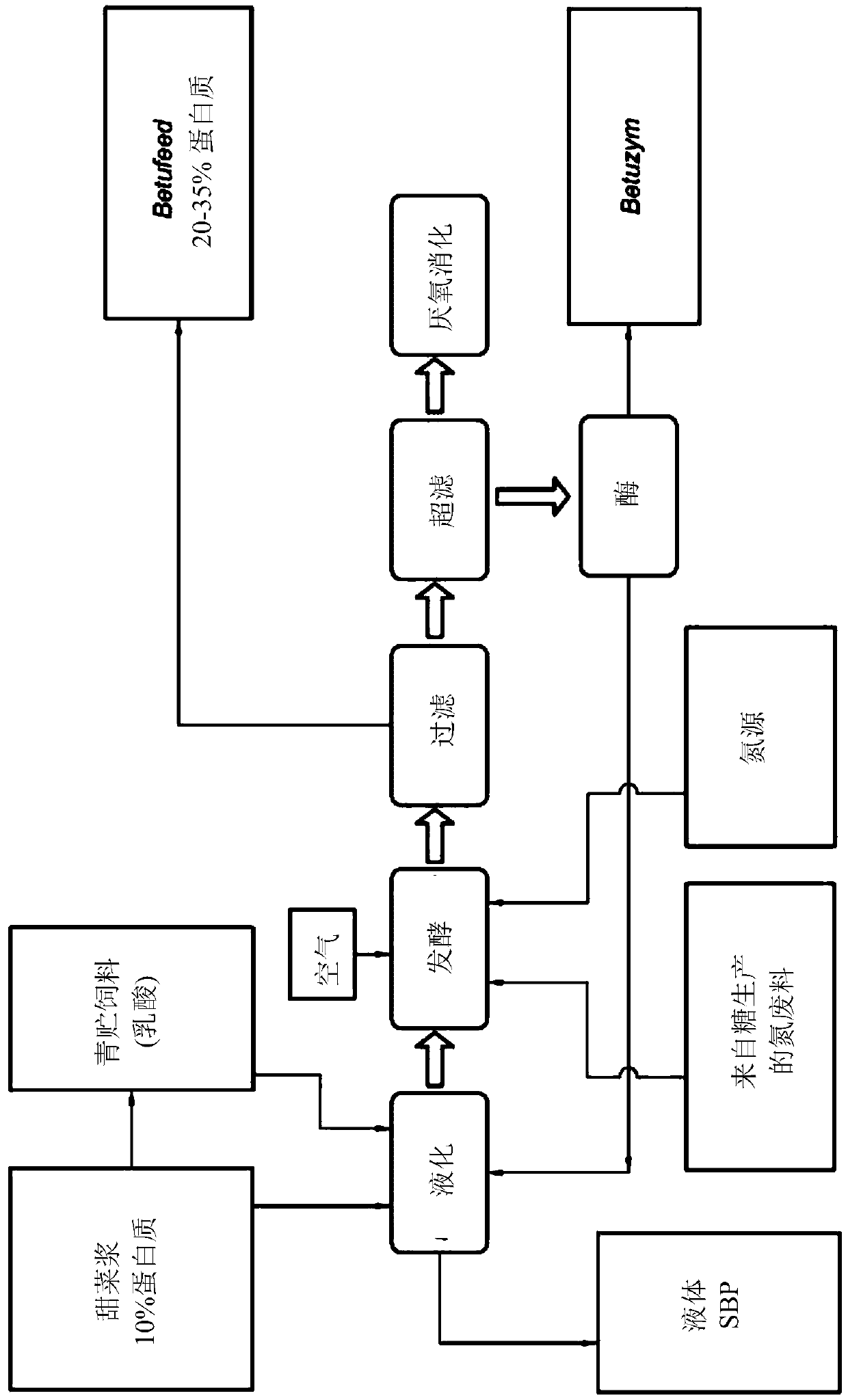

Method used

Image

Examples

Embodiment 1

[0070] Example 1. Production of protein-enriched animal feed from sugar beet pulp

[0071] Thaw 1 ml of frozen Rasamsonia composticola CBS 141695 mycelium (-80°C, glycerol stock solution) and inoculate into 35 ml of yeast extract / glucose medium (each 20 g / L), the medium was sterilized at 121° C. for 20 minutes, and incubated at 45° C. at 220 rpm with an eccentric distance of 25 mm for 48 hours.

[0072] 10 ml of this 48 hour preculture was transferred to the sugar beet pulp medium as follows:

[0073] Prepare 250ml of medium in a 2L baffled Erlenmeyer flask containing sufficient mineral solution of K, P, S, Ca, Mg, Zn, Fe, Mn, Cu (for good fungal growth (US20020039758)), 1.75 gr / L NaNO 3 , 1.75gr / L di-ammonium sulfate, 0.1gr / L yeast extract and 20gr / L Fibrex 500 (commercial beet pulp Nordic Sugar milled to a fine paste). The medium was supplemented with 10 drops of soybean oil to prevent foaming and sterilized at 121°C for 20 minutes.

[0074] After fermentation, the ferme...

Embodiment 2

[0077] Example 2. Production of SCP in a fed-batch process.

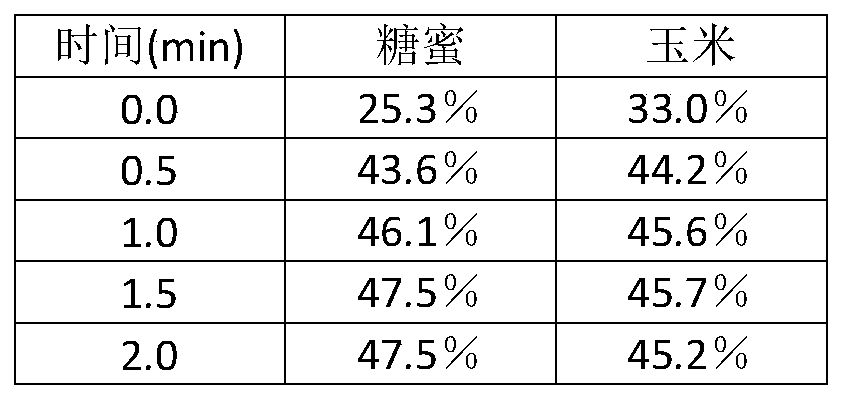

[0078] Beet pulp was liquefied at 45°C to 27% dry matter using 0.02g VisCO Reductase AC100 (Weiss Biotech) per gram of syrup from the silage process. The beet pulp was diluted with water to a dry matter concentration of 8% and shaken in a shaker incubator at 150 rpm with a 25 mm eccentric distance. At the beginning of liquefaction, the pH of the silage was 3.8, and after 3 hours, the liquefied beet pulp was added to the hydrolysis reactor, diluted with water to 5.2% dry matter, and stirred at 400 rpm in a 15 L stirred tank reactor, The temperature was set at 60° C. for another 6 hours and the pH was controlled to pH 4 using 8% ammonia as titrant. The hydrolyzate was then harvested and frozen until used as feed to the fermentation.

[0079]A 1 ml frozen vial (glycerol stock solution at -80°C) of strain Rasamsonia composticola CBS141695 was thawed and added to 35 mL of medium containing yeast extract 20 g / L and gluc...

Embodiment 3

[0082] Example 3. Production of fish from dried SCP

[0083] 525 g of the 33% dry matter biomass filter cake obtained in Example 2 were mixed with wheat gluten 12.4 gr, commercially available fish feed (27 gr) and 3.5 g of calcium carbonate, extruded through a 1 mm extruder and fluidized in Dry in a bed drier at 30°C. 145 g of dry SCP were obtained with about 30.8% protein on dry matter basis. 80% of all protein in this diet comes from SCP. The dried filter cake was ground and sieved on a 0.5mm sieve.

[0084] After feeding a total of 15.4 grams of fresh weight of 7 tilapias per day at 27-28° C. for 30 days, 58.7 grams of fish were obtained, whereas a total of 109.5 grams of feed was added, demonstrating 0.54 grams of fresh fish per gram of feed. The fish are very lively and healthy, love the food and have normal droppings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com