Method for selectively modifying {110} surface of bismuth vanadate with NiOOH assistant

A bismuth vanadate and selective technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of selective modification and preparation technology that have not been reported, and achieve easy mass synthesis, The effect of low price and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of selective modification of NiOOH additives on bismuth vanadate {110} surface is as follows: first prepare 80ml of Na 2 SO 4 (0.1mol / L) solution in a three-necked flask. Then the pH of the above solution was adjusted to 8 with NaOH (0.1 mol / L). Then 0.15g of Pt / BiVO 4 The powder is mixed with the above solution under magnetic stirring to form a homogeneous suspension. Among them, Pt / BiVO 4 For the preparation method, see literature (R.G.Li., et al., Nat. Commun., 2013, 4, 1432.). Then add 219 μL of NiSO to the above suspension with a pipette gun 4 (0.13mol / L). After stirring at room temperature for 15 minutes, it was then illuminated for 5 hours under a xenon lamp (the xenon lamp needs to add a 420nm filter). The reaction product was washed three times with water, and dried in an oven at 40°C for 12 hours to obtain the product.

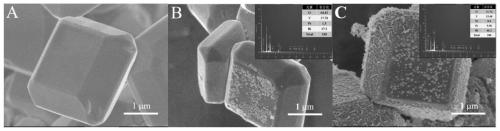

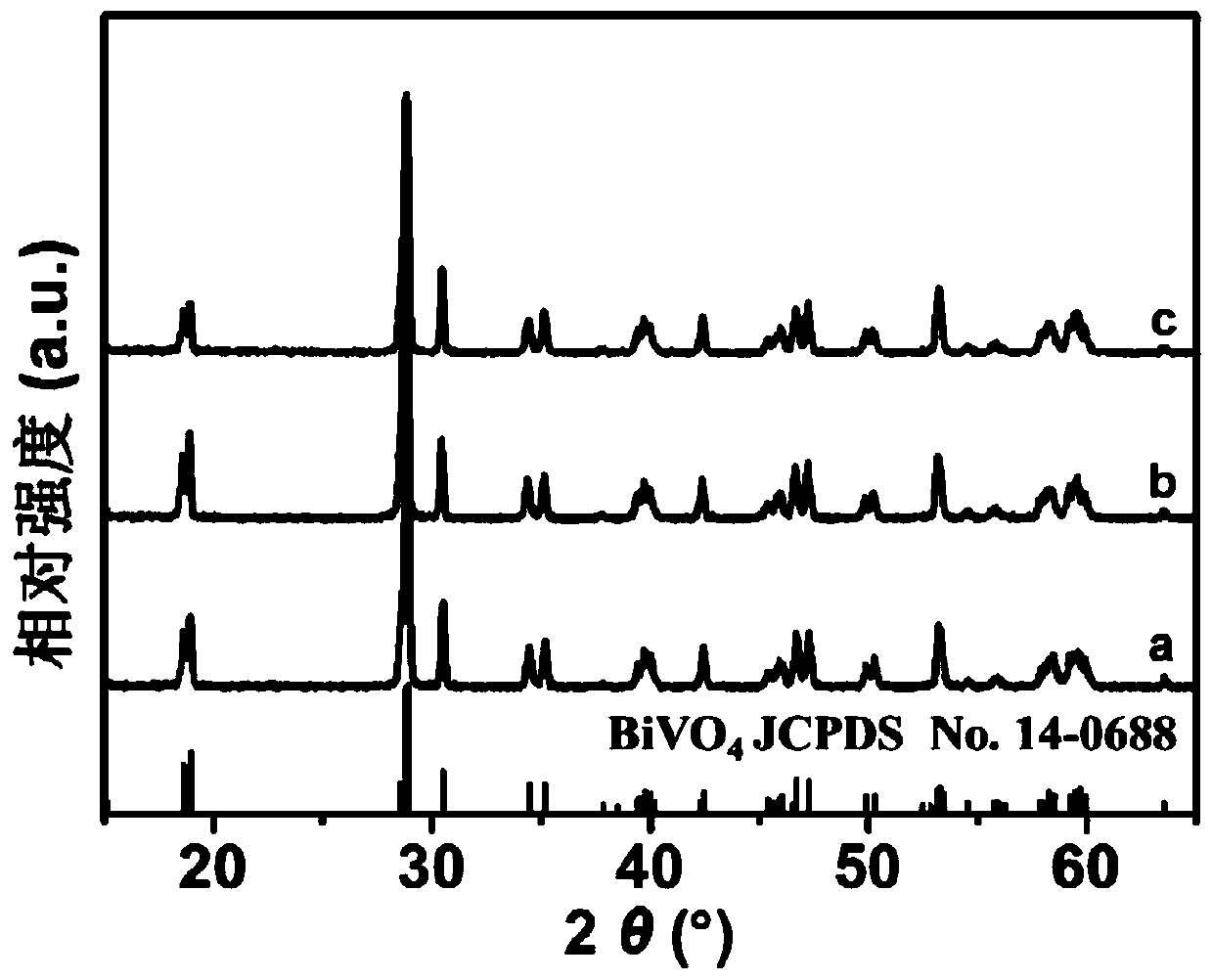

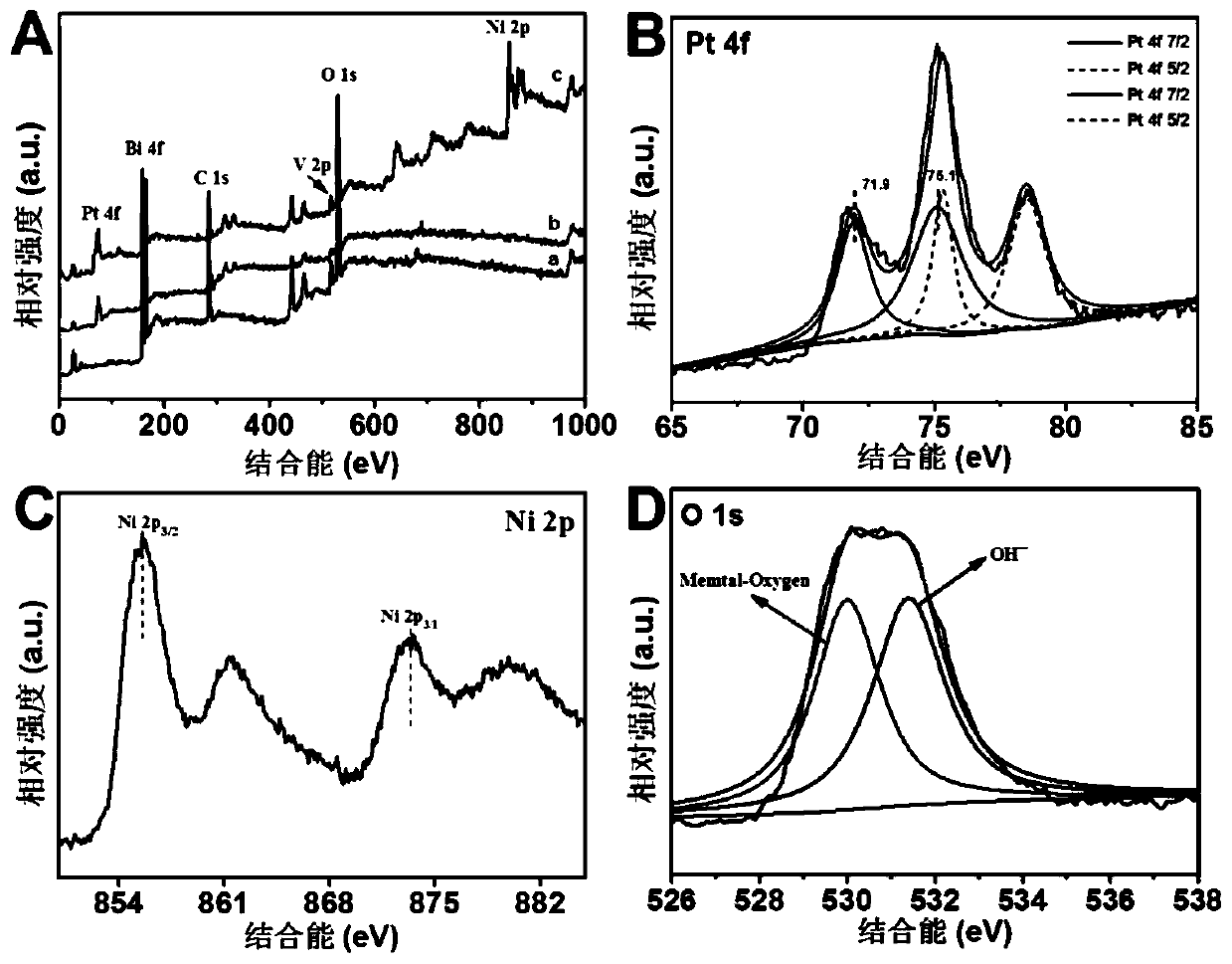

[0025] The characterization method of the selective modification of bismuth vanadate photocatalyst by NiOOH a...

experiment example 2

[0033] In order to test the influence of different electrolyte solutions (sodium sulfate, sodium chloride, sodium nitrate, potassium sulfate, potassium chloride, potassium nitrate) on the photocatalysts selectively modified by bismuth vanadate {110} surface NiOOH additives, except that the electrolyte solutions were different Except that, other conditions such as solution pH (pH=8) and water-soluble nickel salt (nickel sulfate solution) etc. are all the same as in Example 1. The experimental results show that when sodium sulfate, sodium chloride, sodium nitrate, potassium sulfate, potassium chloride, and potassium nitrate are used as electrolyte solutions, NiOOH can be selectively deposited on BiVO 4 {110} face.

experiment example 3

[0035] In order to test the influence of the pH of the solution on the selective modification of NiOOH additives, other reaction conditions such as the light time (5h) and the electrolyte solution (sodium sulfate solution) of the solution were the same as in Example 1 except that the pH of the solution was different. The experimental results show that when the pH of the solution is less than 2, there is no NiOOH formation on the bismuth vanadate {110} surface. Because the strong alkaline environment will dissolve NiOOH, which is not conducive to the formation of NiOOH. When the pH of the solution is greater than 12, NiOOH will be deposited on different sides of the bismuth vanadate randomly deposited on it. When the pH of the solution is in the range of 2-12, NiOOH can be selectively deposited on the bismuth vanadate {110} surface. Therefore, the optimal pH of the solution is 2-12 during the preparation process of selective modification of NiOOH additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com