A kind of flame-retardant hdpe tube and its preparation method

A technology of seed tube and flame retardant synergist, which is applied in the field of plastic product processing, can solve the problems of reduced service life, low HDPE oxygen index, and aggravated combustion, so as to reduce smoke generation, improve flame retardant effect, and improve flame retardant performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

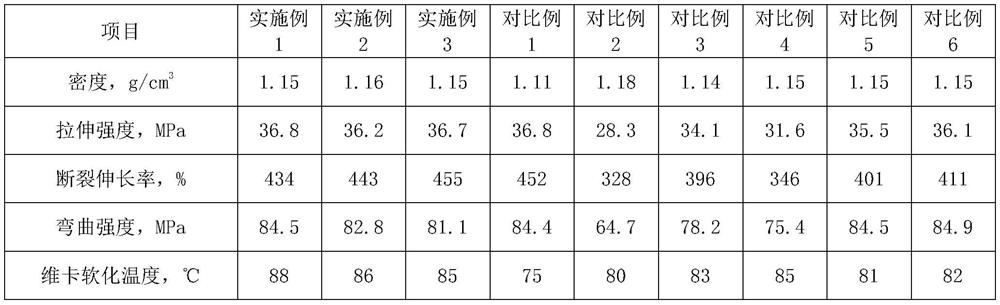

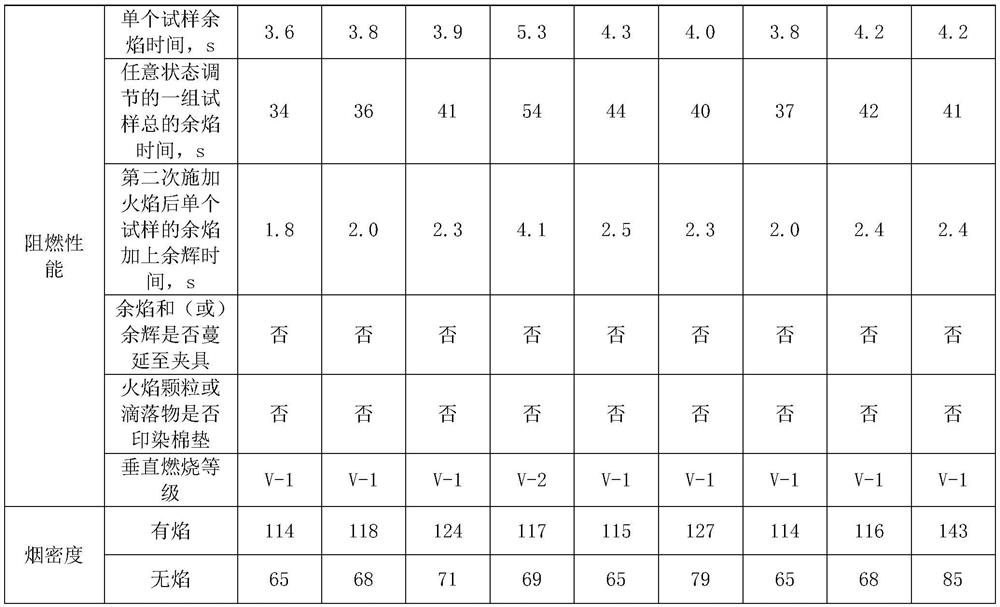

Examples

preparation example 1

[0038] Preparation example 1: 1. get 50kg of aluminum hydroxide and 6kg of medical stone powder, and screen through a 100-mesh sieve after grinding; 2. add 1kg of glycerol monostearate and 100kg of isopropyl to the screened aluminum hydroxide and medical stone powder alcohol, and then ultrasonically dispersed for 5min under the condition of ultrasonic power of 300W to obtain a suspension; 3. Add 1kg of titanate coupling agent to the suspension, raise the temperature to 85°C, stir for 10min at a speed of 1000r / min, and pass After suction filtration and washing, it was dried at a temperature of 160° C. for 8 hours, and then ground and sieved through a 600-mesh sieve to obtain modified aluminum hydroxide.

preparation example 2

[0039] Preparation example 2: 1. get 55kg of aluminum hydroxide and 7kg of medical stone powder, and screen through a 150 mesh sieve after grinding; 2. to add 1.5kg of glycerol monostearate and 110kg of isoglycerol to the screened aluminum hydroxide and medical stone powder. Propanol, and then ultrasonically dispersed for 8min under the condition of ultrasonic power of 320W to obtain a suspension; 3. Add 1.5kg of titanate coupling agent to the suspension, heat up to 90°C, and stir for 13min at a speed of 1500r / min , after suction filtration, washing, drying at a temperature of 170 ° C for 9 hours, and then grinding and sieving through a 600-mesh sieve to obtain modified aluminum hydroxide.

preparation example 3

[0040]Preparation example 3: 1. get 60kg aluminum hydroxide and 8kg medical stone powder, pass through 200 mesh sieves after grinding; alcohol, and then ultrasonically dispersed for 10min under the condition of ultrasonic power of 350W to obtain a suspension; 3. Add 2kg of titanate coupling agent to the suspension, heat up to 95°C, stir at a speed of 2000r / min for 15min, and pass After suction filtration and washing, drying at 180° C. for 10 hours, and then grinding and sieving through a 600-mesh sieve, the modified aluminum hydroxide is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com